10-STEP PROCESS FOR MANUFACTURING STEEL STRUCTURES

Let’s explore the following 10-Step Process for Steel Structure Manufacturing with Tri Viet Steel Building. Steel structures are a type of structure made from steel, widely used in building construction, from houses, offices, factories to public works, bridges, roads,…

1. Overview of Steel Structures

1.1. What Is a Steel Structure?

A steel buildings structure consists of steel components and structures designed and manufactured in factories for assembly into complete structures. These are parts and details assembled from steel, creating load-bearing frameworks for structures. Steel structures are lightweight, rigid, durable, easy to construct, and transport.

1.2. Common Types of Steel Structures:

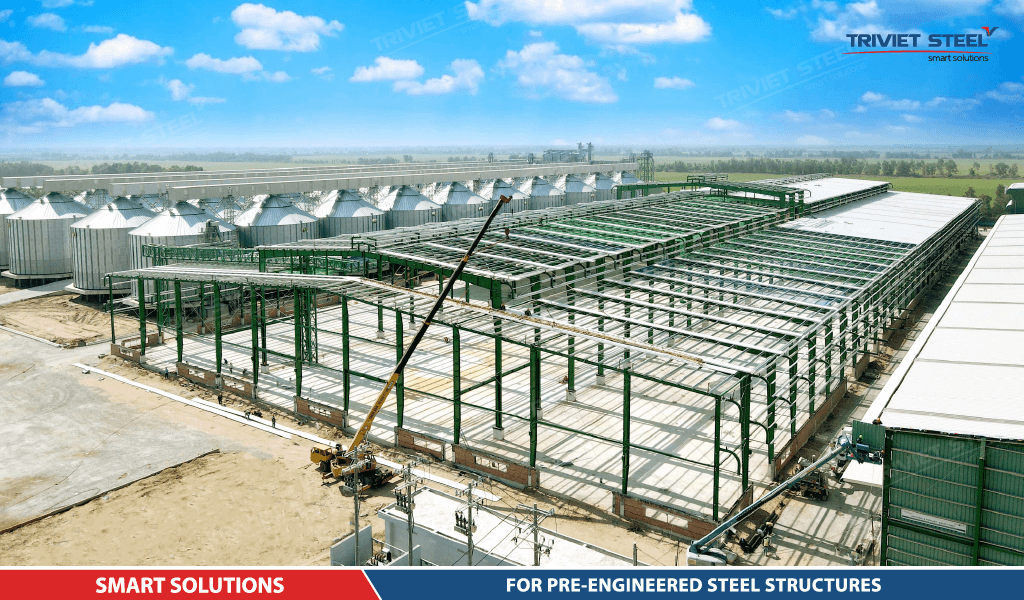

- Pre-engineered steel house structures: used for warehouses, offices, and more.

- Steel bridge structures: used in bridge construction.

- High-rise steel structures: used in skyscrapers.

- Special steel structures: airports, stadiums, and more.

1.3. Benefits of Steel Structures:

- Cost-saving and time-saving due to factory production.

- Easy transport and assembly.

- High durability, excellent load-bearing capacity, and fire resistance.

- Versatility in design and size.

- Reusable and eco-friendly.

2. Manufacturing Process

The manufacturing process of steel structures consists of the following 10 steps:

1. Collection of raw materials:

- Import various types of steel: steel sheets, steel profiles, steel coils with a variety of sizes.

- Steel sheets: are the main material for making frames and walls of the structure. Usually have a thickness of 2mm to 20mm depending on the design requirements.

- Steel profiles: used for purlins, rivets, connecting parts.

- Steel coils: used to reinforce weld joints, increase the rigidity of the structure.

- Thoroughly check: size, quality, cleanliness of steel before entering production.

2. Cutting steel according to design:

- Use modern cutting machines to cut steel into pieces of the required size.

- After cutting, check the size and shape of the details carefully against the design drawings.

3. Pressing to shape the details:

- Details such as sheet wings and partitions are pressed to create the correct shape according to the design.

- The pressing process uses a large compressive force to act on the steel billet to change the original shape.

- After pressing, check the size and accuracy of the detail carefully against the drawing.

4. Welding the details into components:

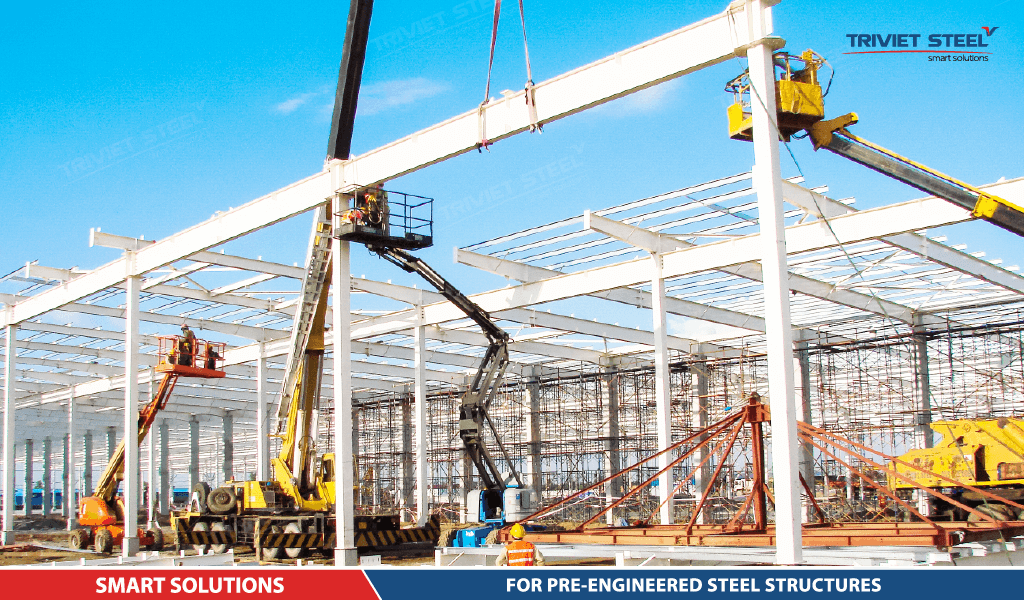

- Use a specialized automatic welding system to weld the steel parts into a complete component.

- Automatic welding ensures high accuracy, beautiful welds and secure connections.

- After welding, check the quality of the welds, the straightness and the edges of the component carefully.

5. Straightening the component:

- The component after welding will be straightened using a specialized machine.

- Straightening helps to remove any warping and ensure the flatness, accurate edges of the component.

- Check the flatness with a ruler, the angle with a specialized angle gauge.

6. Assembly of connecting parts:

- Assemble the auxiliary parts such as bolts, rivets, welds, etc. to connect the parts of the component.

- Use specialized pliers and screwdrivers to tighten the bolts to the correct force.

- Check the position and size of the auxiliary parts carefully before welding.

7. Complete welding:

- Continue welding the auxiliary parts to the component to complete the product.

- Check the strength of the welds carefully, correct any errors immediately.

- The component after welding will be cleaned and painted.

8. Surface cleaning:

- Use a sandblasting system to clean the entire surface of the component.

- Completely remove dirt, rust, slag that affects the quality of the welds and the paint color.

- The surface after cleaning must be dry, clean, rough, and uniform.

9. Protective coating:

- Apply 1-2 coats of anti-rust primer as a base for the component.

- Spray a PU coating with a standard thickness.

- The paint helps to protect the component from the effects of the environment, extending its lifespan.

10. Final inspection:

- Check the entire component before packaging and storing.

- Steel structures are carefully stored to prevent scratches and strong impacts.

- Transport to the construction site for installation safely and in accordance with the process.

3. Important Criteria in Steel Structure Manufacturing

3.1. Quality Steel Raw Materials:

One of the most important factors in steel structure manufacturing is the raw materials. We ensure that the materials must have clear certificates of origin and must comply with international standards such as ASTM, BS, JIS, and other standards. The quality of the materials contributes significantly to the durability

3.2. Modern Equipment System:

To meet the high requirements of steel structure manufacturing, we use a system of modern, standard and stable machinery. These devices help to create quality products and ensure uniformity in the production process.

3.3. Experienced Engineers and Workers:

The team is a key factor in steel structure manufacturing. At Tri Viet Steel, we ensure that the team of engineers and workers are professionally trained and have reliable experience in the field of steel structure manufacturing. This ensures that they have the knowledge and skills necessary to create quality products.

3.4. Strict Quality Control:

The team is a key factor in steel structure manufacturing. At Tri Viet Steel, we ensure that the team of engineers and workers are professionally trained and have reliable experience in the field of steel structure manufacturing. This ensures that they have the knowledge and skills necessary to create quality products.

4. Conclusion:

With these standards and criteria, Tri Viet Steel is committed to providing quality and reliable steel structure products for all construction projects. We always comply with the highest standards and ensure that all products meet the strictest standards.

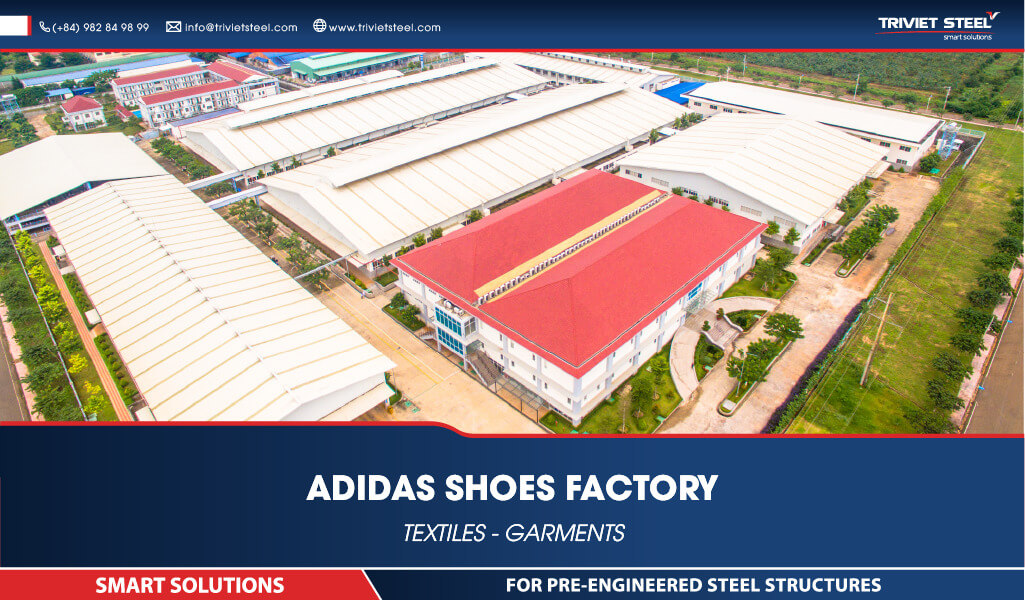

5. Tri Viet Steel – Professional and Reliable Steel Structure Manufacturing Unit

With nearly 20 years of experience in the design, manufacturing and installation of prefabricated steel buildings, Tri Viet Steel Building is one of the leading steel structure manufacturing and construction units in Vietnam.

- Modern machinery and equipment, advanced technology imported from Europe.

- Experienced, skilled team of engineers, regularly trained.

- Committed to providing the best quality steel structure products, perfect service.

- Quick and affordable advice, quotation for steel structure production and installation.

Tri Viet Steel Building has confidently asserted itself as a reliable partner in the field of prefabricated steel buildings. Please contact us today to explore potential projects and create outstanding works for a sustainable future.

English

English Tiếng Việt

Tiếng Việt