EXPORTED STEEL STRUCTURES: A LANDSCAPE OF POTENTIAL AND OPPORTUNITIES FOR VIETNAM

In an increasingly interconnected global economy, the exported steel structures sector is emerging as a promising area for Vietnamese businesses. With the growing global demand for infrastructure development, the export market for steel structures presents lucrative opportunities for domestic manufacturers.

Vietnam, with its competitive labor costs and improving product quality, is steadily asserting its presence on the global steel structure manufacturing map. Many Vietnamese enterprises are already participating in the supply chain for major international projects, contributing to the country’s export value and enhancing the reputation of its industrial sector.

1. Current Status of Vietnam Exported Steel Structures Industry

In recent years, Vietnam exported steel structures industry has made significant strides. According to data from the General Department of Vietnam Customs, the export value of all types of steel (including steel structures) reached 8.55 billion USD in 2022, a 5.8% increase compared to 2021. Exported steel structures and related products contributed significantly to this figure.

The primary export markets for Vietnamese steel structures include:

- The United States: This is the largest market, accounting for approximately 30% of total export value.

- Japan: Ranking second, capturing about 15-20% of the market share.

- ASEAN Countries: Representing approximately 15% of the market share.

- The EU and Australia: Each market accounts for around 10% of the market share.

2. Advantages and Challenges of Vietnam Exported Steel Structures Industry

2.1. Advantages:

- Abundant Labor Force with Competitive Costs: Vietnam offers a large pool of skilled and unskilled labor at competitive wages.

- Strategic Geographical Location: The country’s location facilitates exports to major markets within the region.

- Government Support: Supportive government policies encourage industrial growth and exports.

- Improved Logistics Infrastructure: Enhancements in logistics infrastructure streamline the transportation of goods.

2.2. Challenges:

- Intense Competition: Vietnamese manufacturers face fierce competition from established steel-producing countries like China and South Korea.

- Fluctuating Input Material Prices: The industry is susceptible to price volatility of raw materials, particularly crude steel.

- Stringent International Quality Standards: Meeting increasingly demanding technical requirements and quality standards of the international market poses a challenge.

- Shortage of Skilled Technical Labor: The industry faces a shortage of highly skilled technical personnel specialized in steel structure fabrication.

3. Exported Steel Structure Standards: A Key Factor

To compete effectively in the international market, Vietnamese exported steel structure manufacturers must adhere to stringent international standards. Some common standards include:

- ASTM (American Society for Testing and Materials): A widely recognized standard used globally, particularly important for exporting to the US market.

- JIS (Japanese Industrial Standards): Essential for exporting to the Japanese market.

- EN (European Standards): Required for exporting to EU countries.

- AS (Australian Standards): Crucial for the Australian and New Zealand markets.

Compliance with these standards is not just a mandatory requirement; it’s also a way to enhance a company’s reputation and competitiveness in the global marketplace. Vietnamese businesses need to invest in quality management systems, testing equipment, and personnel training to ensure products consistently meet these standards.

4. Opportunities and Challenges: Seizing and Overcoming

Alongside the challenges, Vietnam exported steel structure industry possesses numerous opportunities for robust future growth:

4.1. Opportunities:

- Growing Global Demand: Global demand for steel structures continues to rise, particularly in developing countries experiencing rapid urbanization.

- Free Trade Agreements (FTAs): FTAs offer tariff advantages, boosting the competitiveness of Vietnamese steel structures.

- Manufacturing Shift: The trend of manufacturing shifting from developed to developing countries creates opportunities for Vietnam to attract investment and adopt modern technologies.

4.2. Challenges:

- Intense Competition: Stiff competition persists from major steel structure exporting countries like China, South Korea, and Japan.

- Stringent Technical Barriers to Trade (TBTs): Increasingly strict TBTs require companies to continuously improve product quality and meet specific market requirements.

- Shortage of Skilled Labor: A shortage of highly qualified personnel, especially engineers and skilled technical workers, remains a challenge.

5. Development Solutions: Elevating the Position of Vietnamese Exported Steel Structures

To effectively harness the potential and overcome challenges, Vietnam exported steel structure industry should focus on the following key solutions:

- Enhancing Competitiveness: Invest in technological innovation, adopt advanced quality management systems, improve labor productivity, and minimize production costs to create high-quality steel structures at competitive prices.

- Market Diversification: While maintaining existing markets, actively seek and expand into new potential markets, particularly in ASEAN, South America, and Africa.

- Promoting Trade: Participate in international trade fairs and exhibitions, develop product showcase websites, connect with foreign partners, and promote the Vietnamese steel structure brand globally.

- Developing Human Resources: Train a high-quality workforce to meet the increasing demands of modern steel structure manufacturing.

- Improving Support Policies: The government should implement policies that support steel structure businesses in accessing preferential loans, participating in training and technology transfer programs, and promoting trade.

6. Solutions for Vietnam Exported Steel Structure Industry Development

6.1. Enhancing Competitiveness:

- Invest in modern, automated production technologies to increase productivity and product quality.

- Optimize production processes and reduce costs to achieve price competitiveness.

- Focus on high-value-added steel structure products that meet specific market demands.

6.2. Invest in Research and Development (R&D):

- Develop new steel structure products aligned with green and sustainable building trends.

- Research the application of new materials and advanced technologies in steel structure manufacturing.

6.3. Training and Human Resource Development:

- Collaborate with universities and colleges to train specialized personnel.

- Organize internal training programs to enhance employee skills.

- Attract foreign experts for technology and experience transfer.

6.4. Strengthening Trade Promotion:

- Participate in international steel and construction trade fairs and exhibitions.

- Build a strong brand for Vietnamese steel structures in the international market.

- Utilize e-commerce channels to reach global customers.

7. Triviet Steel – Your Trusted Partner for Exported Steel Structure Projects

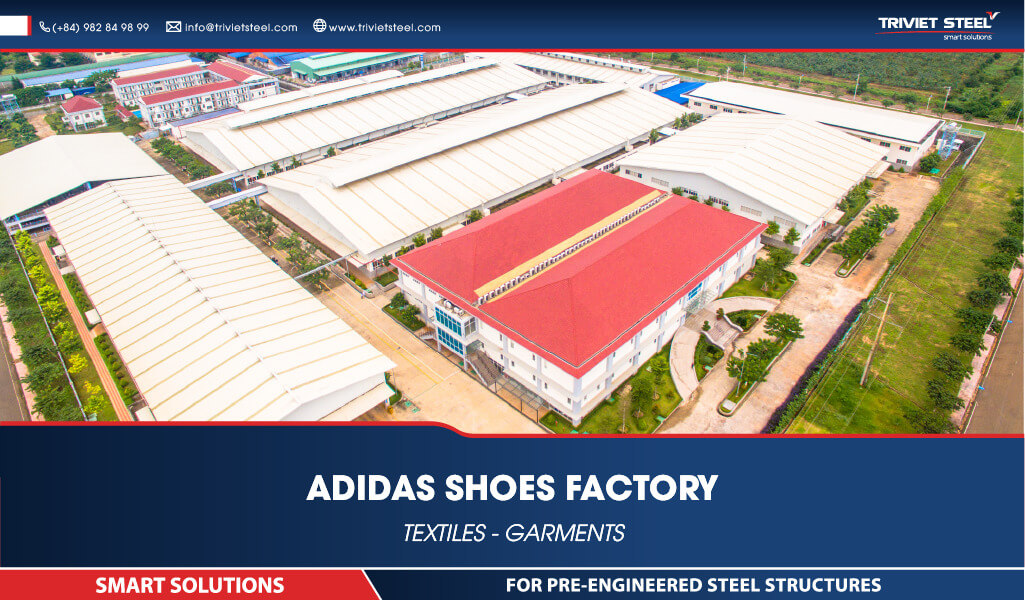

As a pioneer in Vietnam steel structure manufacturing sector, Triviet Steel is a proud and reliable partner for numerous key domestic and international projects. With modern facilities, advanced production technology, and a team of skilled engineers and workers, we are committed to providing customers with high-quality steel structures that meet the most stringent requirements.

Triviet Steel Strengths:

- Large Production Capacity: A modern factory with substantial capacity, meeting diverse demands for volume and types of steel structures.

- Advanced Technology: Utilizing automated production technology ensures high precision and minimizes errors.

- International Quality Standards: Products meet international quality standards such as ASTM (US), JIS (Japan), EN (Europe), and AS (Australia).

- Experienced Personnel: A team of highly qualified and experienced engineers and workers specializing in steel structure design and fabrication.

- Professional Services: Dedicated consulting, design support, fabrication, and comprehensive steel structure erection services tailored to meet customer requirements.

Triviet Steel has affirmed its position as a leading exported steel structure manufacturer in Vietnam, contributing to the global reach of the Vietnamese brand. We are committed to continuous improvement and innovation to provide customers with the best products and services, partnering with clients on modern and sustainable projects.

English

English Tiếng Việt

Tiếng Việt