WHAT IS THE STEEL STRUCTURE IN PRE-ENGINEERED STEEL BUILDINGS ?

In the era of industrialization and technological advancement, pre-engineered steel buildings have become an indispensable part of the construction industry. In this article, we will delve deeper into steel structures, from the concept to their specific applications, along with the fascinating aspects of pre-engineered steel buildings.

1. Steel Structures – From Concept to Deeper Understanding

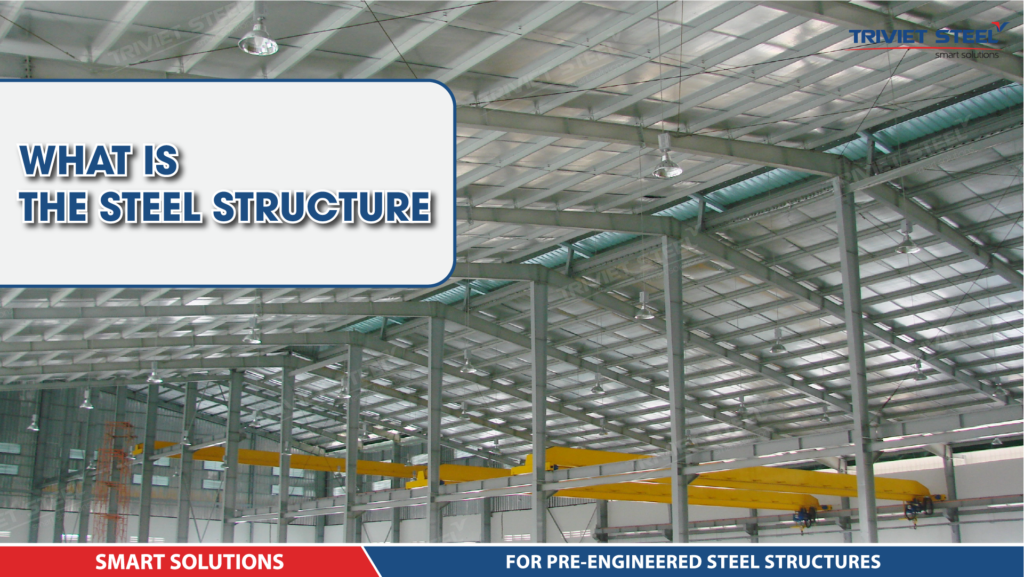

1.1. What is Steel Structure ?

Steel structure, as the name suggests, involves the use of steel as the primary material to construct various building structures. Steel is chosen for its robust load-bearing capacity, durability, and excellent corrosion resistance. These advantages have made steel structures the top choice for numerous critical construction projects worldwide.

1.2. Advancements in Steel Structure Technology

Technology is continually advancing, and steel structures are no exception. Progress in technology makes the design and construction of structures using steel structures more efficient, saving time and resources, and ensuring higher safety standards for both workers and end-users.

1.3. Common types of steel structures

The steel frame structure is widely used and common in various native buildings, including warehouses, factories, industrial workshops, shopping centers, office buildings, conference centers, and transportation infrastructure such as airports and train stations. Here are some typical structural types:

- Frame structure: beams and columns

- Grid structure: arches and lattice structures

- Beam bridge

- Suspension bridge

- Truss structure: bars or trusses

- Arch bridge

- Vaulted architecture

- Suspension bridge

- Truss bridge: truss components

2. Pre-Engineered Steel Buildings – Modernity in Construction

2.1. What are Pre-Engineered Steel Buildings?

Pre-Engineered Buildings are a type of building made up of steel structures, designed and manufactured with exact quantities and detailed dimensions according to technical drawings at the factory and then brought to the factory. works to carry out the erection and finishing phase.

When installed, the components will be linked together by bolts. That way we can understand the process of making the finished product (including a combination of inspection and quality control steps. ) of a pre-engineered steel building through 3 main stages: Design – Manufacturing – Installation.

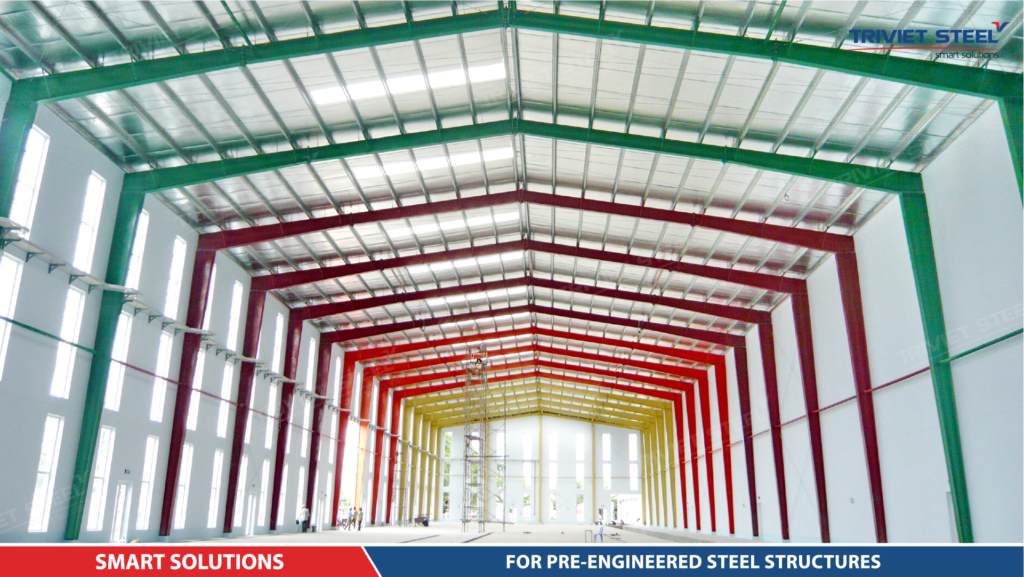

2.2. Structure of pre-engineered buildings

Pre-engineered steel buildings have 3 main components:

- Skeletal structure: a combination of columns, steel truss, beams…

- Sub-structural system: Purlins (Z, C, and U purlins…), struts for the top of the wall, rib, wall beams, and other components.

- Covering system and accessories such as roof corrugated iron, wall corrugated iron…

In addition, to serve the needs of investors and customers, the designs of pre-engineered steel buildings can integrate the following structures:

- Mezzanine floor, crane girders (helping to support the crane system), roof support system, walkways…..

- Detailed accessories: canopies, roof extensions, frills, gutters, gutters, roof tops, ventilation systems, bracing cables…

3. Benefits of Using Steel Structures and Pre-Engineered Buildings

3.1. Cost Savings:

Pre-engineered steel buildings are one of the construction solutions that help save costs while still achieving high efficiency. The cost of constructing Pre-engineered steel buildings is lower compared to projects using reinforced concrete, thanks to the savings in raw materials.

3.2. Flexibility and Convenience in Design:

Unlike structures built with reinforced concrete, Pre-engineered steel buildings are transportable and easy to assemble. Steel components are manufactured in factories, allowing for changes or upgrades to the structure by simply drilling holes and bolting new components together, facilitating quick and convenient installation.

3.3. Lightweight Structures:

An advantage of Pre-engineered steel buildings is their ability to be combined with super lightweight materials. This helps reduce the load-bearing pressure while introducing new and environmentally friendly design options by utilizing secondary materials, thereby limiting construction waste in the environment.

3.4. High Mold Resistance Capability:

Pre-engineered steel buildings possess a high resistance to mold and moisture due to their well-designed water-resistant features and the use of a vertical roof system, water drainage components, and roof flashing.

3.5. Fast Construction Time:

For small-scale projects that demand rapid construction progress, pre-engineered steel buildings are a worthy consideration. Pre-fabricated components are manufactured to size and shape specifications in the design, so when construction takes place on-site, labor only needs to assemble them, significantly reducing construction time.

4. Disadvantages of Pre-engineered Steel Buildings

While pre-engineered steel buildings have many advantages, they also come with the following disadvantages:

4.1. Low Fire Resistance:

Steel is not easily flammable, but when temperatures reach around 500-600 degrees Celsius, steel becomes ductile and loses its strength. To address this drawback, manufacturers often apply fire-resistant coatings to enhance the fire resistance of pre-engineered steel buildings.

4.2. Susceptible to Corrosion in Hot and Humid Weather:

Humid climates like those in Vietnam can lead to corrosion and rusting of steel. Therefore, pre-engineered steel frames often require an external layer of paint to protect them.

4.3. Relatively High Maintenance Costs:

As a consequence of the above two disadvantages, additional maintenance costs are incurred to improve fire resistance and corrosion protection for the structure.

5. Conclusion

Steel structures and pre-engineered steel buildings are not only modern trends in the construction industry but also intelligent and sustainable solutions for the future. Their flexibility, durability, and time-saving characteristics have proven their value in constructing a wide range of structures, from high-rise buildings to bridges and industrial facilities. They not only help conserve resources but also contribute to building a greener and more sustainable future for our planet.

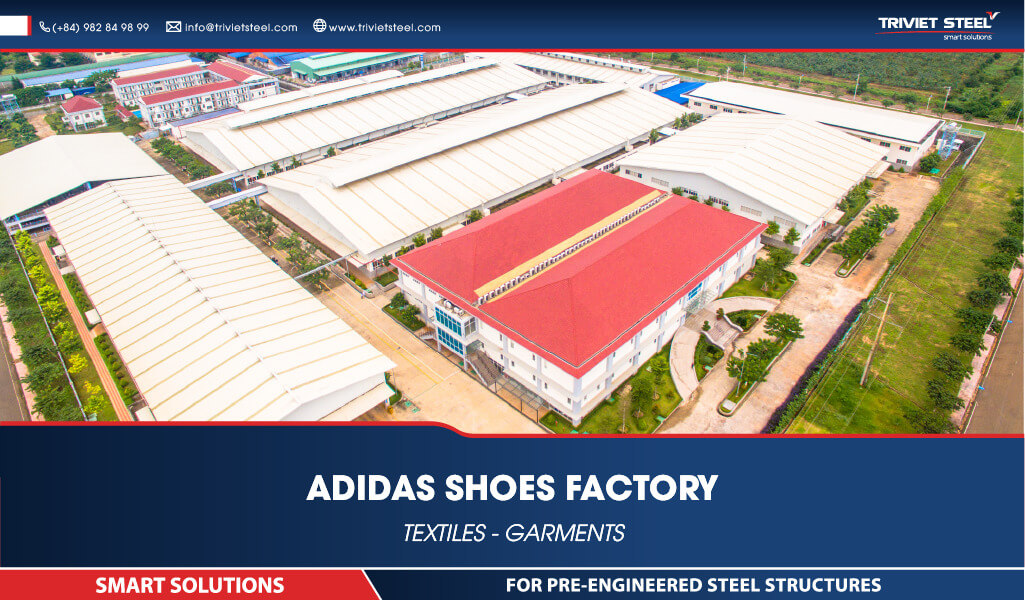

6. Tri Viet Steel Building- A Leading Steel Structure And Pre-Engineered Steel Buildings Company In Vietnam

6.1. Overview of Tri Viet Steel Building Company

Tri Viet Steel Building Company was established in 2004 with the goal of becoming one of the top enterprises in the field of steel structures in Vietnam. With over 18 years of experience, we have completed more than 500 projects of various sizes across the country, ranging from industrial, residential, commercial constructions to special projects such as airports, bridges, and terminals.

We take pride in being one of the companies capable of designing, manufacturing and installing prefabricated steel buildings according to customer requirements, with a team of professional and dedicated engineers, architects, and installation experts. We consistently adhere to strict technical standards and quality management processes to ensure the highest level of customer satisfaction with our products and services.

6.2. Why Choose Tri Viet Steel Building Company?

Tri Viet Steel is one of the leading companies in the field of steel structures in Vietnam. We take pride in the following factors:

1. Professional and Dedicated Staff:

Tri Viet Steel boasts a team of professionals including engineers, architects, designers, welders, and installers with high qualifications and years of experience in the steel structure industry.

2. Modern and Advanced Infrastructure:

Currently, Tri Viet Steel operates with two production workshops covering an area of 10,000 square meters each, equipped with the most modern and advanced machinery and equipment in the steel structure industry. We have the capability to produce high-quality steel structure products with high precision and meet international technical standards.”

3. Best Product and Service Quality:

Tri Viet Steel always prioritizes product and service quality. We utilize imported materials and accessories from reputable global suppliers to ensure that our structural steel products are of high durability, safety, and aesthetics.

We also maintain a strict quality management system, adhering to quality inspection, control, and certification processes according to ISO 9001:2015, ISO 14001:2015, and OHSAS 18001:2007 standards.

4. Rapid and On-Time Construction:

Tri Viet Steel employs an efficient pre-engineered steel building construction process that allows us to complete projects within a timeframe of 15 to 30 days, depending on the project’s scale and specifications. We consistently adhere to our commitments regarding project timelines, providing transparent and timely progress reports to our clients.

English

English Tiếng Việt

Tiếng Việt