PRE-ENGINEERED STEEL BUILDINGS – CONSTRUCTION TREND IN 2023

Pre-engineered steel buildings are increasingly popular in Vietnam due to their outstanding advantages in fast construction and cost-effectiveness. Let’s learn more about this smart construction method.

1. What is Pre-Engineered Steel Buildings ?

A pre-engineered steel building is a structure designed and manufactured in a factory, with steel components, and then transported and assembled on-site. Pre-engineered buildings have the advantages of saving construction time, cost, and high aesthetic appeal.

The process of pre-engineered building construction consists of three stages: Design – Manufacturing – Installation. In the design phase, engineers create detailed technical drawings for each part of the building. The manufacturing stage involves fabricating steel components according to the design specifications at the factory. Finally, these components are transported and assembled into a complete structure on-site.

In this way, pre-engineered buildings save time and costs while ensuring aesthetics and construction quality. This is a trend favored by many investors.

1.1. Advantages of Prefabricated Steel Buildings

- Quick construction, time-saving.

- Consistent quality due to mass production.

- Cost-effective and efficient.

- Can be relocated and reassembled in another location.

1.2. Where Are Prefabricated Steel Buildings Suitable?

- Warehouses, factories, workshops

- Offices, stores, hotels, restaurants

- Schools, hospitals, dormitories

- Residential houses, villas, apartments

- Stadiums, outdoor stages

In general, most civil and industrial construction projects can apply this construction technology.

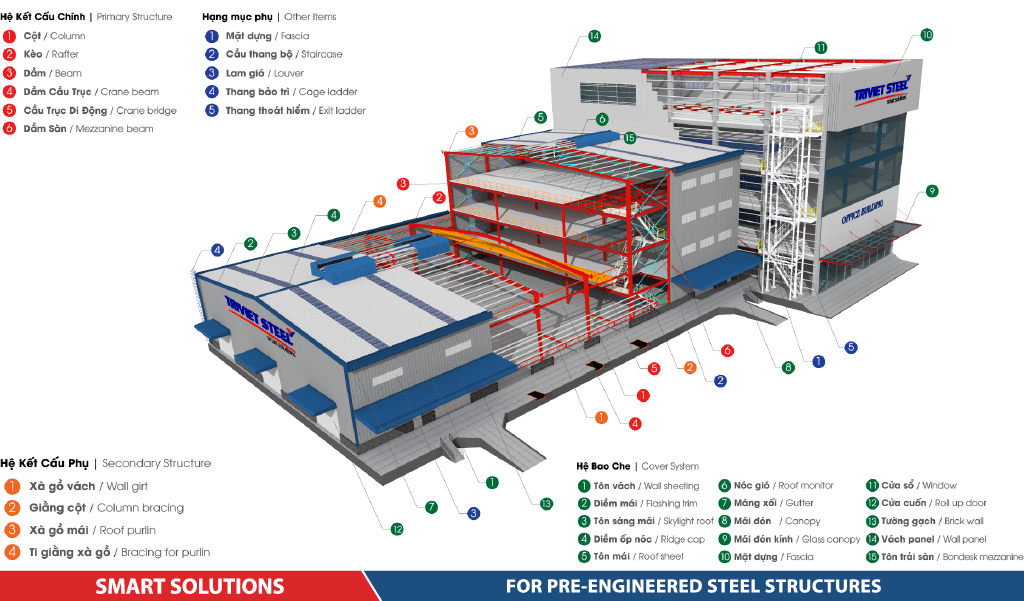

2. Structure of Pre-Engineered Steel Buildings

It consists of three main components:

- Frame Structure: A combination of steel columns, beams, and trusses

- Secondary Structural System: Purlins (Z, C, and U purlins), roof bracing, wall studs, wall girts, and other structural elements.

- Cladding and Accessories: Roofing sheets, wall panels, and additional accessories.

Furthermore, to meet the specific needs of the owner or customer, prefabricated buildings can integrate additional structures such as:

- Mezzanine floors, crane beams (for supporting crane systems), bracing systems, and walkways.

- Various accessories: canopies, extensions, flashings, downspouts, ridge caps, ventilation systems, and cable bracing.

3. Design and Production Process of Pre-Engineered Steel Buildings

3.1. Prefabricated Steel Buildings Design Process

- Step 1: Receiving Architectural Drawings from the Customer

When a customer intends to construct a building, Trí Việt Steel will receive the architectural drawings for the project. - Step 2: Calculation and Detailed Cost Estimation

Based on the drawings, a meticulous calculation is performed to create a detailed cost estimate, including materials, labor, production, and installation costs. - Step 3: Contract Signing with the Customer

After the customer approves the cost estimate, both parties sign a contract to finalize the scope of work. - Step 4: Design and Construction Drawing Preparation

Tri Viet Steel will prepare detailed construction drawings to guide the construction and installation processes. - Step 5: Detailed Production Drawing Design

Detailed production drawings are designed as a basis for manufacturing prefabricated steel components. - Step 6: Installation Drawing Design

Installation drawings provide detailed instructions for assembling the steel components into a complete structure.

In this way, the production process for prefabricated steel structures involves six meticulous steps, from design to production and construction, all requiring precision and accuracy.

3.2. Prefabricated Steel Buildings Structure Production Process

- Step 1: Material Selection

The input materials are various types of steel sections and steel coils. It is essential to choose high-quality steel that meets the standards.

- Step 2: Cutting Steel into Small Parts

The steel is cut into individual bars or sheets of appropriate dimensions for component fabrication.

- Step 3: Shaping Components

After cutting, the steel parts are bent and shaped to form components such as beams, columns, and trusses.

- Step 4: Welding Components into Structures

Once the components are shaped, they are welded together to form complete structures.

- Step 5: Aligning and Adjusting Structures

Inspecting and adjusting the shape of the structures to ensure accuracy.

- Step 6: Welding for Surface Finishing

Re-welding joints to achieve a smooth surface finish on the components.

- Step 7: Grinding and Surface Shot Blasting

Grinding to smooth the surface, removing any rough edges or welding marks. Shot blasting to enhance shine and durability.

- Step 8: Surface Coating

Applying a surface coating and paint to the components to improve corrosion resistance and aesthetic appeal.

- Step 9: Packaging and Transportation

The completed components are carefully packaged and transported to the construction site.

The Pre-engineered Steel Buildings component production process ensures quality at each step to deliver a perfect end product.

3.3. Prefabricated Steel Buildings Construction Process

- Step 1: Site Preparation

– Level the ground, prepare the foundation

– Install underground drainage systems

– Pour concrete for the floor

- Step 2: Erection of Steel Frame Structure

– Transport steel components to the construction site

– Assemble columns, beams, and connect joints using bolts

– Install trusses, purlins, and roof bracing

- Step 3: Roof Installation

– Attach roofing materials such as color steel sheets, cold-formed steel, or panels to the steel frame

– Set up a rainwater drainage system, gutters, and downspouts

- Step 4: Completion

– Construct interior partitions if necessary

– Install entrance doors, windows, and staircases (if applicable)

– Finish the flooring

– Install electrical and lighting systems

4. Price List of the Latest Pre-Engineered Steel Buildings

4.1. Factors Affecting Cost

- Building area: The larger the area, the lower the average unit price.

- Function of the building: Warehouses and factories are cheaper than houses and offices.

- Type of materials used: Prefabricated steel, color steel, glass, stone, etc.

- Grade of the building: Higher grades are more expensive.

- The degree of interior finishing

- Construction location: Cities have higher unit prices.

- Investment time: High season has higher unit prices.

4.2. Reference price list of some types of Prefabricated Steel Buildings:

To get the best price, you should send a direct quotation request to Tri Viet Steel to receive immediate advice and free quotation.

| Type of building | Unit price/m2 |

| Factory, warehouse, factory | Contact |

| Office, shop, hotel, restaurant | Contact |

| School, hospital, dormitory | Contact |

| House, villa, apartment | Contact |

| Stadium, outdoor stage | Contact |

5. Advantages of Pre-Engineered Steel Buildings:

- Cost savings of 10-25% compared to traditional solutions.

- Construction progress is 3-5 times faster than traditional methods.

- Consistent and accurate construction quality thanks to industrial production.

- Large load-bearing capacity, high building life, and much better durability over time than traditional building materials.

- One can easily relocate, disassemble, and reassemble pre-engineered steel buildings multiple times without compromising quality.

- Diverse designs, suitable for many purposes, and can easily expand or shrink space.

6. Notes for the design and construction of Pre-Engineered Steel Buildings:

- Design that is suitable for the climate and topography of the project.

- Choose the right type of prefabricated steel and the optimal structural solution.

- Ensure high aesthetics, in harmony with the surrounding landscape.

- Comply with design standards and regulations.

- Closely monitor the production, transportation, and installation of steel components.

7. Frequently Asked Questions About Pre-Engineered Steel Buildings

- How many types of Prefabricated Steel Buildings are there ?

- There are several types of prefabricated steel homes, including warehouses, workshops, villas, residential houses, and large industrial structures. Each type has its own unique design and application.

- Are Prefabricated Steel Buildings reliable ?

- Prefabricated steel homes can be very reliable if designed and constructed properly. Using experts and adhering to technical standards are essential to ensure the safety and durability of the structure.

- Are Prefabricated Steel Buildings suitable for all types of projects ?

- Prefabricated steel homes are suitable for many types of projects, but they are not always the best choice. The decision depends on the specific needs of the project and environmental conditions..

- Can Prefabricated Steel Buildings be reused?

- Yes, some aspects of prefabricated steel homes can be reused after the structure is no longer in use. This helps reduce construction waste and optimize resource utilization.

8. tri viet steel – The Expert in Design – Manufacturing – Installing Pre-engineered Steel Buildings

Tri Viet Steel is proud to be a leading company with over 20 years of experience in the design – manufacturing and Installing of Pre-engineered Steel Buildings.

Innovative Design: Tri Viet Steel has a team of professional engineers and designers who are always innovating and leveraging advanced technology to create breakthrough design solutions for prefabricated steel buildings. We are committed to providing you with unique solutions that meet the objectives of your project.

Quality Manufacturing: With state-of-the-art equipment and advanced manufacturing processes, Tri Viet Steel ensures reliable and significant product quality. We leverage high-tech to produce strong steel frames with superior load-bearing capacity and durability, helping to save time and resources for your project.

Professional Construction: Construction capability is a key factor in the successful completion of a project. Tri Viet Steel has a professional construction team that always adheres to the schedule and ensures safety during construction. We are committed to bringing you satisfaction through completed projects.

Attentive Consulting: We understand that building prefabricated steel buildings can be challenging. Tri Viet Steel’s consulting team will always listen to and advise you throughout the project, helping you make smart decisions and save money.

Tri Viet Steel has confidently established itself as a reliable partner in the prefabricated steel building industry. Contact us today to explore potential projects and create outstanding structures for a sustainable future.

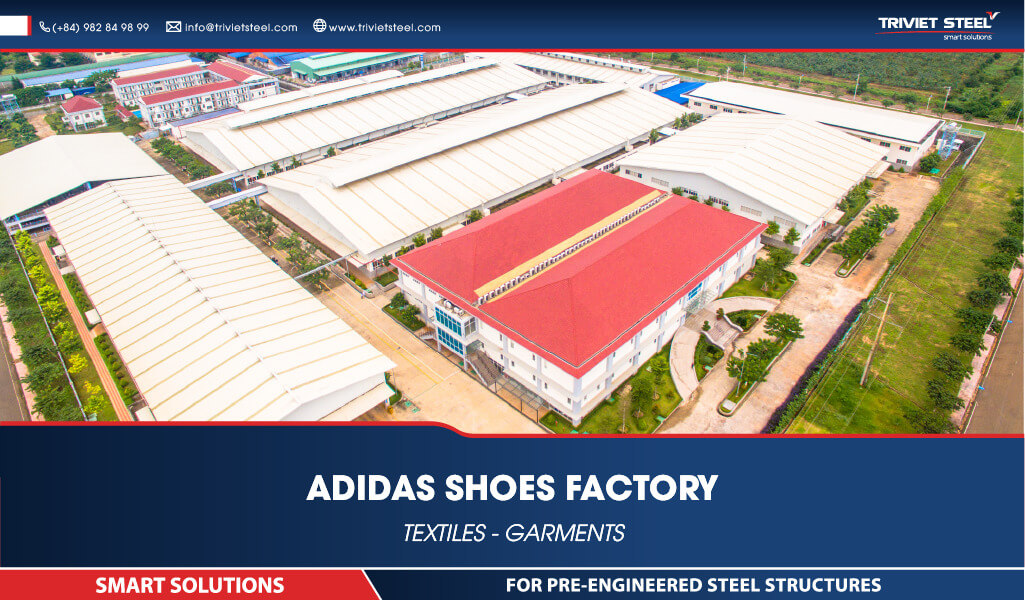

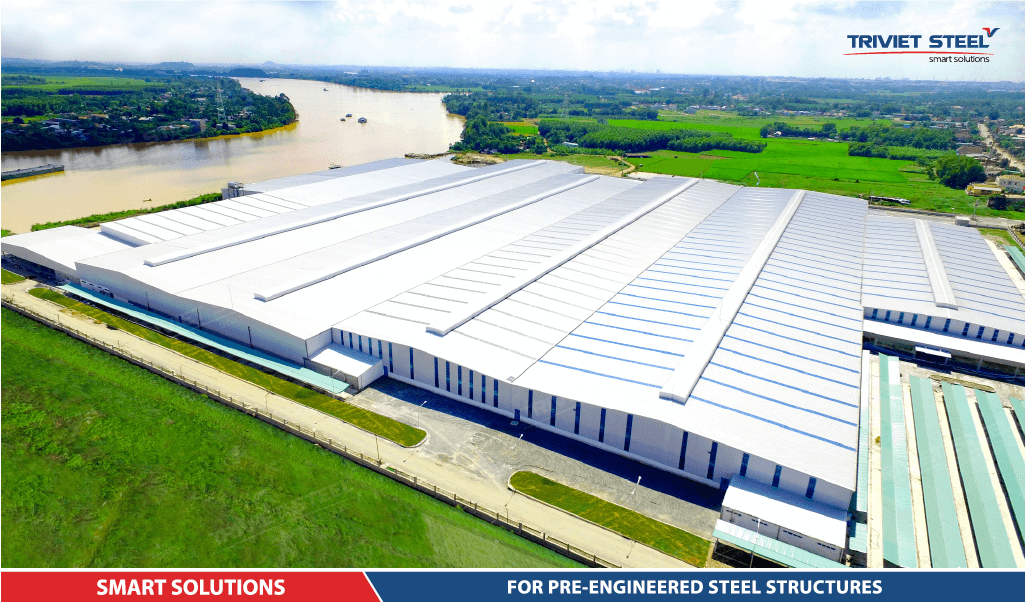

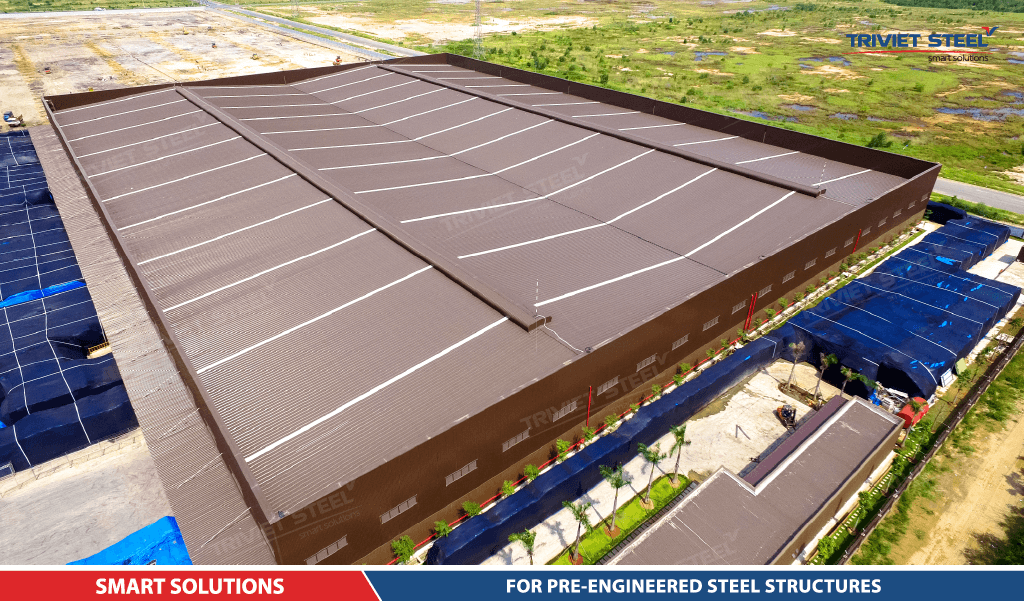

9. Featured Pre-Engineered Steel Buildings Projects

Pre-engineered Steel Buildings can be designed in a variety of styles. Here are some of the large, multi-industry projects in Vietnam that Tri Viet Steel has designed and built:

English

English Tiếng Việt

Tiếng Việt