EFFICIENT SOLUTION OF PRE-ENGINEERED STEEL BUILDINGS CONSTRUCTION

Pre-engineered steel buildings are increasingly becoming a popular trend in construction and building projects. Moreover, with their rapid construction, cost-effectiveness and high durability. Pre-engineered steel buildings emerge as a great choice for modern construction projects.

If you’re seeking the latest 2023 pricing information for pre-engineered steel buildings construction, delve into this article for a comprehensive and reliable overview.

1. What is Pre-engineered steel buildings ?

Firstly, let’s delve into the concept of “Pre-engineered steel buildings.”

Pre-engineered steel buildings, also known as “composite steel buildings”, refer to a construction method where the primary structural components of the project are manufactured and assembled at a specialized production facility, then transported to the construction site for assembly.

Incorporating pre-engineered steel building structures into construction projects is not only a modern trend but also brings numerous superior advantages. The steel structure comprises these three main components:

- Steel Frame: The steel frame is responsible for bearing the primary load of the construction, including columns, beams, braces, and purlins designed to provide stability and durability. Furthermore, connective accessories ensure the seamless integration and firm fixation of the steel frame, creating a solid foundation for the entire structure.

- Partition Walls: Transitioning to partition walls, these play a crucial role in sound and thermal insulation. In addition, they use insulated panels or other materials to create individual spaces.

- Roofing System: Shifting our focus to the roofing system, it plays a role in protecting the entire construction from the impact of weather and external environmental factors. Simultaneously, insulated panels or other materials are used to build the roof, helping to prevent rainwater and external heat from entering the interior. This dual function not only creates a comfortable environment but also serves as a protective barrier for the valuable assets inside.

The pre-engineered steel building structure not only optimizes construction time but also provides significant stability, durability, and insulation performance for the house.

2. Benefits & Advantages of Pre-Engineered Steel Buildings in Construction

Before delving into the pricing details, let’s explore the benefits that pre-engineered steel buildings offer. These are the strengths of using pre-engineered steel buildings:

2.1. Time Optimization:

Manufacturers produce pre-engineered steel buildings in advance, allowing for quick assembly and reducing construction time compared to traditional methods.

2.2. Cost Savings:

Readily available materials and efficient production processes help minimize the risk of cost overruns and enhance budget predictability in construction projects.

2.3. Durability and Safety:

Designers create pre-engineered steel buildings to withstand harsh weather conditions, ensuring fire resistance, termite resistance, and resilience against natural disasters.

2.4. Customization:

Various pre-engineered steel building design models are available, allowing for customization to meet the specific needs of a project.

3. Influencing Factors on Pricing

The quotation for pre-engineered steel buildings construction can vary based on several factors, including:

- Size and design of the project: Larger and more complex projects may require more resources.

- Quality of materials: The choice of material quality and the source of material supply also affect the cost.

- Construction location: Geographic location and environmental conditions can increase transportation costs and installation work.

4. Pre-engineered Steel Buildings Design and Construction Process

The pre-engineered steel building design and construction process is a complex undertaking carried out by a professional team to ensure the safety and efficiency of the project. Here is an overview of this process:

Step 1: Customer Requirements Determination

Before commencing any design work, it is essential to understand the customer’s requirements. This process involves identifying the construction site, determining the intended purpose of the structure, taking budget constraints into account, and considering other factors that may influence the design and construction.

Step 2: Architectural Design

Upon gathering information from the customer, the team of architects will create architectural drawings. This involves defining the shape, size, and external appearance of the pre-engineered steel building. Furthermore, the design process includes calculating and integrating architectural elements such as windows, entryways, and interior features.

Step 3: Engineering Design

After obtaining the architectural drawings, the engineering team takes on the responsibility of conducting the technical design. They specify the type of steel to use, calculate load-bearing capacity, and verify that the design adheres to technical and safety standards.

Step 4: Manufacturing and Pre-fabrication of Steel

Once the design is finalized, the construction team will use the technical drawings to manufacture and pre-fabricate the steel components. The factory will fabricate these parts, and the construction team will transport them to the construction site.

Step 5: Construction

Once the steel components are ready, the construction process begins at the construction site. Construction workers will assemble the steel parts according to the drawings, using specialized techniques and equipment to ensure accuracy and safety during the construction process.

Step 6: Completion and Inspection

Once the construction team finishes the prefabricated steel structure, they will proceed with tasks such as painting and installation. Subsequently, a technical inspection should be conducted to ensure safety and compliance with standards.

Step 7: Handover to the Customer

Finally, after all construction and inspections have been completed, the project will be handed over to the customer. Pre-engineered steel buildings construction often bring many benefits such as rapid construction speed, stability, durability, and high customization capabilities.

Overall, the process of designing and constructing prefabricated steel buildings is a complex one that requires close collaboration between various departments to ensure the success of the construction project.

5. Conclusion

The above is a summary of the essential information regarding the latest 2023 Pre-engineered steel buildings construction quotation. Pre-engineered steel buildings are a modern, time-efficient, cost-effective, and environmentally friendly construction solution.

If customers are in need of Pre-engineered steel buildings construction, please contact Tri Viet Steel immediately:

6. Why Choose Tri Viet Steel For Pre-engineered Steel Buildings Construction

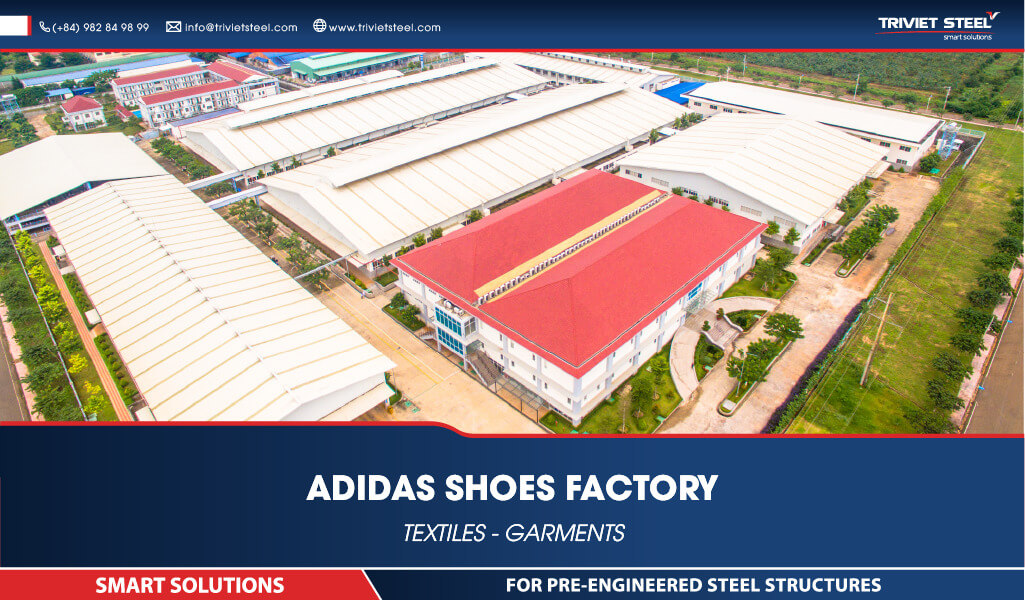

6.1. Tri Viet Steel Building Company

Tri Viet Steel Buildings with headquartered in Vietnam, has built a strong reputation in the construction industry by engaging in the production and design of steel structures. The company, with a mission to offer high-quality steel structure solutions, has actively participated in numerous significant projects, spanning from residential to large industrial ventures.

With a commitment to quality and service, Tri Viet Steel continues to contribute to the sustainable development of the construction industry in Vietnam and internationally.

6.2. 5 Reasons to Choose Tri Viet Steel for Pre-engineered steel buildings construction

Why should you choose Tri Viet Steel for Pre-engineered steel buildings construction ? This is an important question when you are searching for a reliable partner for your construction project. Below are the reasons why we are confident that Tri Viet Steel is a good choice for you:

- 1. High-quality standards:

Tri Viet Steel is committed to providing you with top-quality prefabricated steel building products in the market. We employ modern technology and strict quality standards to ensure that your products perform optimally and have a long lifespan. - 2. Experience and professionalism:

With many years of experience in the Pre-engineered steel buildings industry, our team of experts has been involved in and successfully completed numerous large projects nationwide. We understand how to coordinate and execute all tasks professionally and efficiently. - 3. Convenience and time-saving:

Pre-engineered steel buildings construction from Tri Viet Steel are manufactured in our factory, reducing construction time at the site. This not only saves time but also reduces costs and risks during the construction process. - 4. Excellent customer service:

We always listen to and promptly meet all customer requirements. We are committed to accompanying you from the design phase to project completion to ensure your satisfaction with the final results. - 5. Value for investment:

The combination of high quality, optimal performance, and reasonable prices makes choosing Tri Viet Steel a smart investment for your project. We always strive to provide the best value for our customers. - In summary, Tri Viet Steel takes pride in being a reliable partner in the field of prefabricated steel building construction. We bring together the perfect combination of quality, experience, and excellent customer service to ensure the successful and efficient completion of your project.

English

English Tiếng Việt

Tiếng Việt