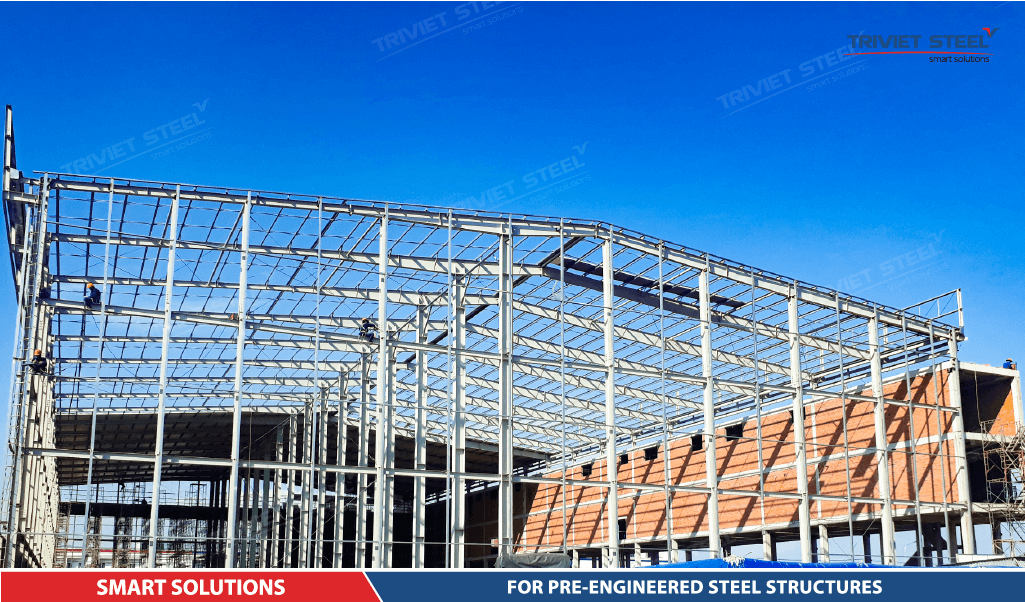

PRE-ENGINEERED STEEL BUILDINGS INSTALLATION – A GROWING TREND

Pre-engineered steel buildings are becoming one of the popular and efficient choices for construction projects in 2023. With technological advancements and changes in the construction industry, using Pre-engineered steel buildings offers significant benefits for investors and contractors. In this article, we will explore the important trends in Pre-engineered steel buildings installation at the end of 2023.

1. What is Pre-Engineered Steel Buildings ?

Pre-engineered steel buildings are a type of structure constructed using pre-fabricated steel components produced in factories and then transported to the construction site for assembly. Pre-engineered steel buildings offer several distinct advantages:

- Cost-effectiveness: Pre-engineered steel buildings generally have lower upfront construction costs compared to traditional concrete and steel buildings.

- Faster construction: The assembly time for pre-engineered steel buildings is approximately one-third of the time required for traditional concrete and steel structures.

- High load-bearing capacity: These buildings can withstand heavy loads and offer high structural strength.

- High flexibility: Pre-engineered steel buildings can be designed and constructed in various shapes and sizes, making them suitable for various applications.

- Longevity: Pre-engineered steel buildings have a long lifespan, often up to 50 years.

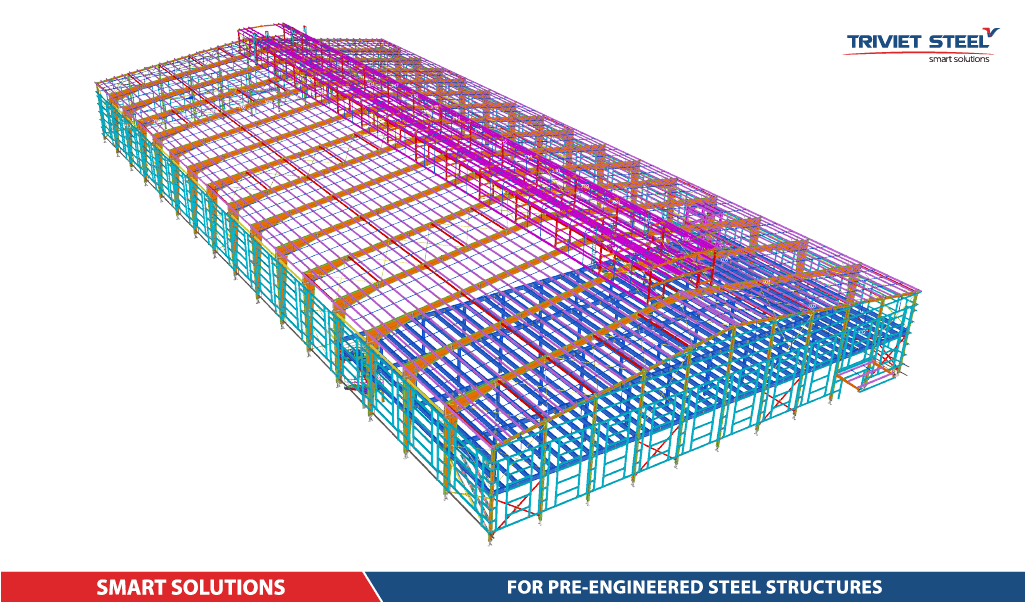

We can categorize the production and construction of pre-engineered steel buildings into three primary stages: design, manufacturing, and installation.

1.1. Structure of Pre-engineered steel buildings

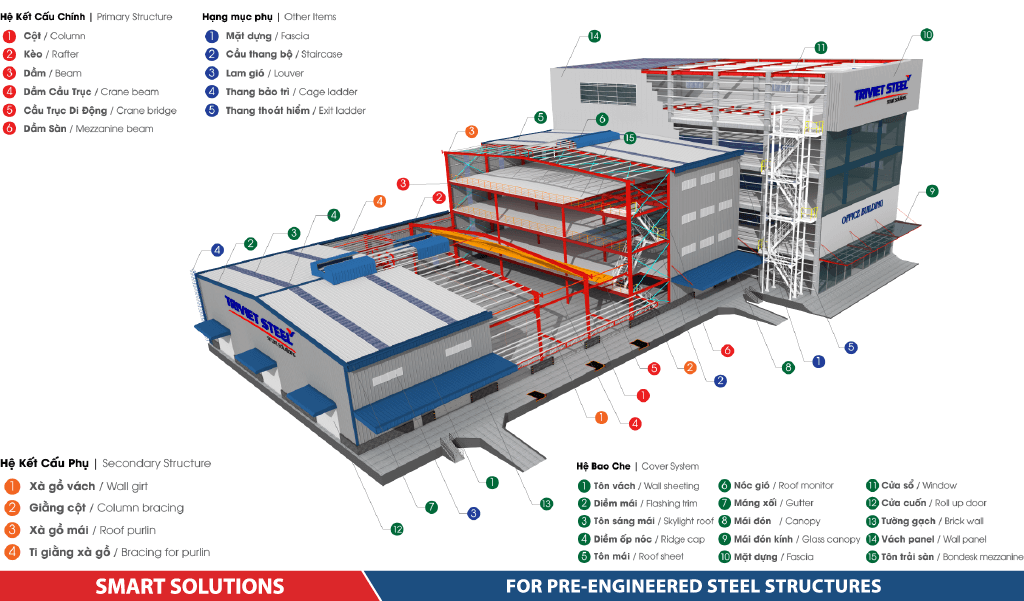

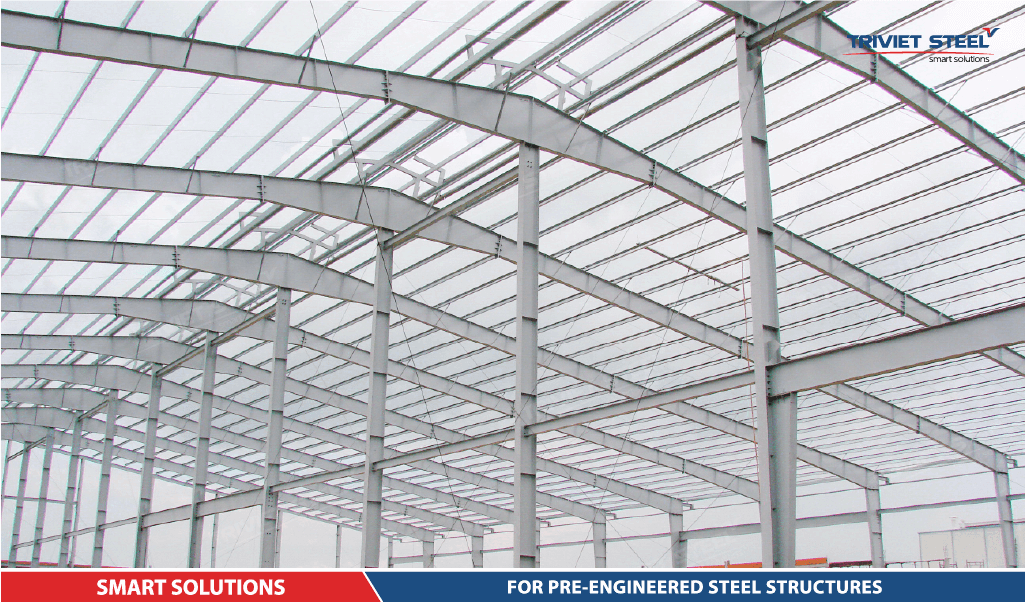

Pre-engineered steel buildings consist of 3 main components:

- Structural frame: This is the primary load-bearing part of prefabricated steel buildings, including columns, trusses, and steel beams.

- Secondary structural system: It includes purlins, bracing elements, wall studs, and wall beams.

- Roof and wall cladding systems and accessories: These components comprise roof sheets, wall sheets, etc.

1.2. Pre-engineered steel buildings Installation Process

The following steps carry out the installation process of Pre-engineered steel buildings.

- Level, compact, and lay a concrete foundation layer to prepare the construction site.

- Assemble steel components according to the design drawings to create the structural frame.

- Install purlins, bracing elements, wall studs, and wall beams following the design drawings to complete the secondary structural system installation.

- Install roof sheets, wall sheets, etc., based on the design drawings to complete the installation of roof and wall cladding systems.

2. Why Pre-Engineered Steel Buildings Are Becoming a Top Choice?

2.1. Convenience and Time Savings

Installing pre-engineered steel buildings reduces construction time compared to traditional methods. Factories manufacture prefabricated components in factories and construction crews then assemble them on the construction site, significantly saving time and resources.

2.2. Customization to Suit Needs

Pre-engineered steel buildings not only save time but also provide flexibility for customization. You can tailor the design, size, interior structure, and other elements to meet your specific needs and style.

2.3. Environmental Resilience

Pre-engineered steel buildings are designed to withstand harsh weather conditions such as rain, storms, and high temperatures, making them a safer choice in changing climate conditions.

Engineers often design these buildings with insulation and energy-saving systems, thereby reducing energy consumption and electricity costs in the long term while also benefitting the environment.

2.5. Long-Term Investment

Installing pre-engineered steel buildings is not just construction but also a long-term, valuable investment. The durability of materials and customization options can increase the property’s value over time.

3. Late 2023 Pre-Engineered Steel Building Installation Trends

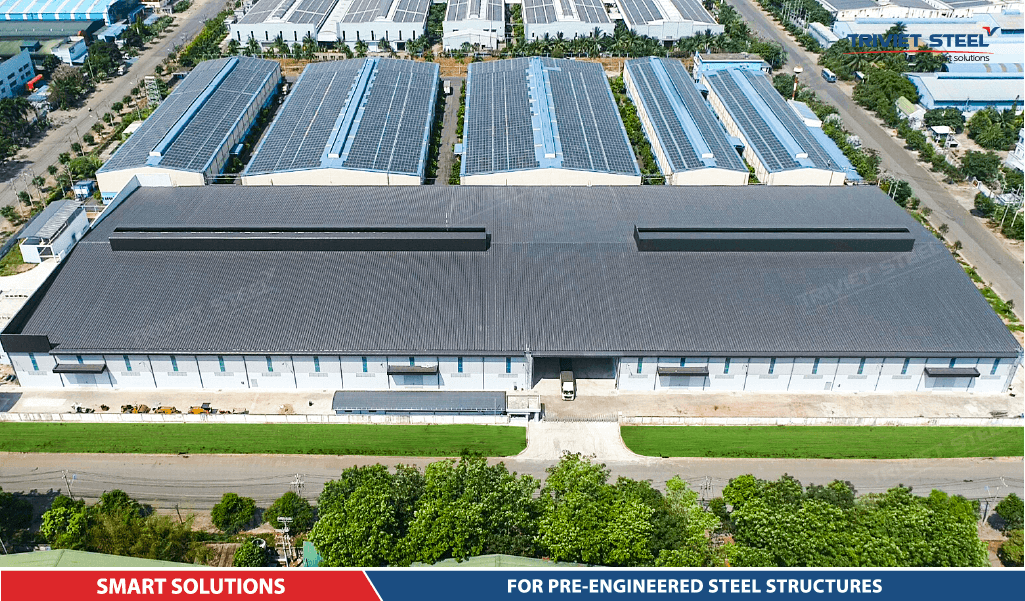

3.1. Enhanced Sustainability

With growing environmental concerns, pre-engineered steel building projects focus on using eco-friendly materials and energy-efficient construction methods.

3.2. Technology Integration

Advancements in technology have brought new solutions to the construction industry, including pre-engineered steel buildings. Technologies like BIM, CAD, VR/AR make the design, construction, and management of these buildings more convenient and efficient.

3.3. Diverse Customization and Design

Customers demand unique and personalized projects. Pre-engineered steel buildings offer flexibility in design, from size to technical features, allowing you to build structures that meet specific goals.

3.4. Safety as a Top Priority

In addition to speed and cost savings, the construction industry knows pre-engineered steel buildings for their safety. Strictly controlled production processes adhere to safety standards, reducing the risk of accidents and project delays.

3.5. Economic Value and Time Savings

Using pre-engineered steel buildings minimizes construction time and costs. Production in factories and on-site installation reduces the time needed compared to traditional construction, resulting in cost savings and improved profitability.

4. Key Considerations for Pre-Engineered Steel Building

Installation Select a reputable construction contractor: A trustworthy contractor ensures material quality, proper construction techniques, and on-time completion.

Thoroughly inspect material quality: Steel materials used for pre-engineered steel buildings must meet quality standards and have clear origins.

Prioritize labor safety: The installation of pre-engineered steel buildings requires skilled labor and a focus on labor safety to prevent accidents.

Adhere to installation procedures: Strictly follow installation procedures to ensure quality and safety for the project.

5. Conclusion

In late 2023 and beyond, people expect the trend of installing pre-engineered steel buildings to continue due to the clear benefits it offers. Advancements in technology and design will make pre-engineered steel buildings more diverse and efficient.

These trends not only signify the growth in the construction industry but also demonstrate a commitment to sustainable construction and environmental protection. Due to its efficiency and resource savings, industry experts expect pre-engineered steel buildings to remain a top choice in the construction industry in the future.

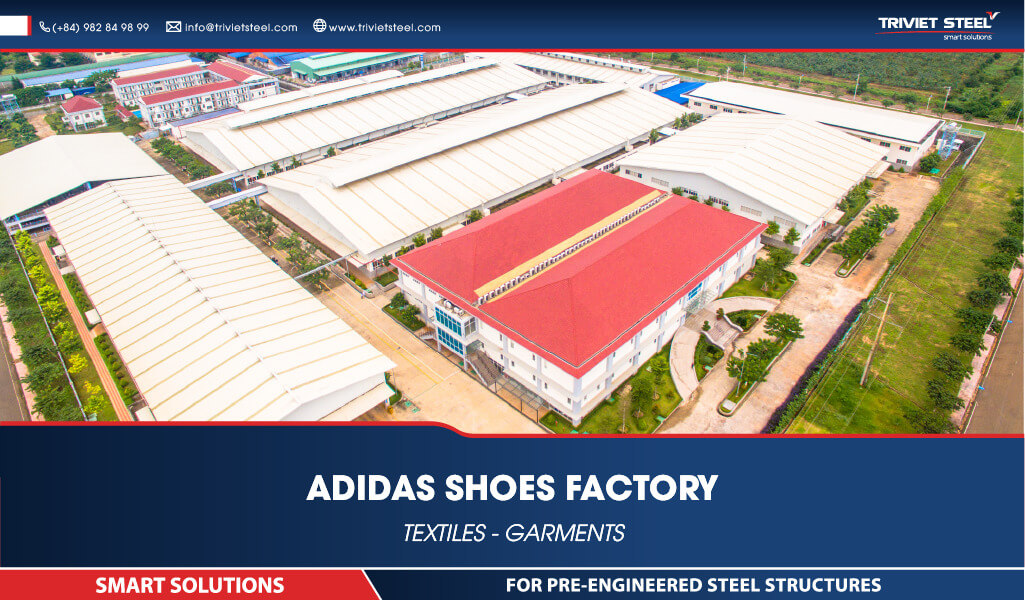

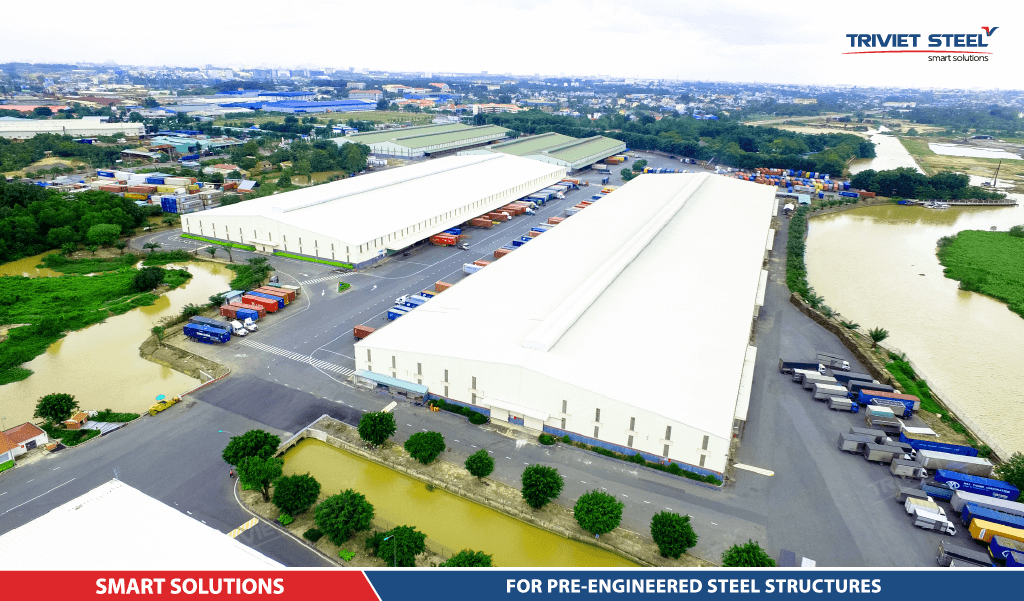

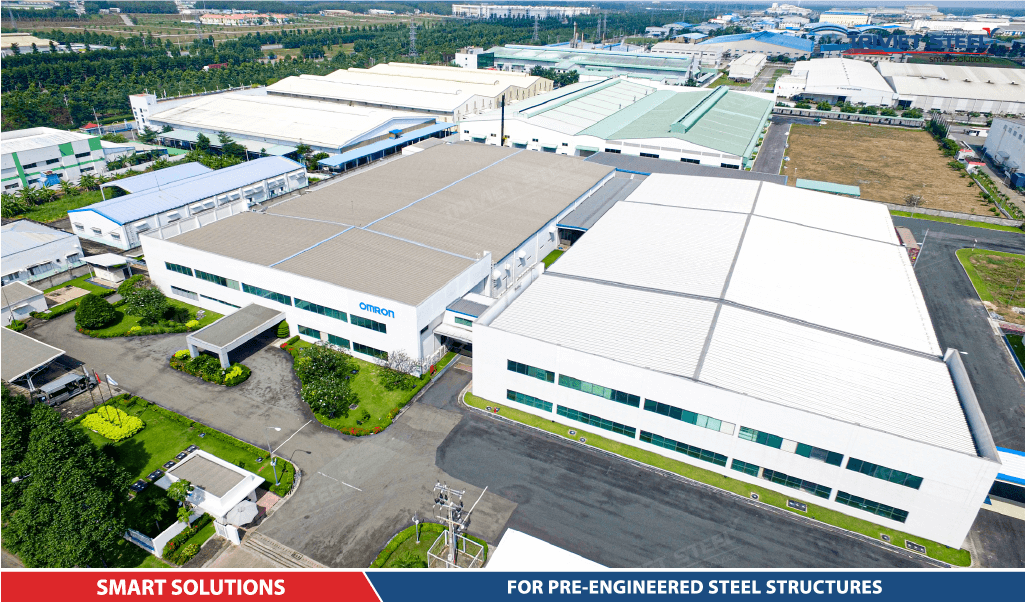

6. Tri Viet steel – A Trustworthy Pre-Engineered Steel Building Installation Company – Quality

Tri Viet Steel possesses a team of skilled engineers and experienced workers. The company uses modern and advanced machinery and equipment to ensure project quality. Tri Viet Steel commits to providing high-quality pre-engineered steel building projects to customers at competitive prices.

Reasons to Choose tri viet steel for Pre-Engineered Steel Building Installation

Why should you choose Tri Viet Steel for your pre-engineered steel building installation? It’s an important question when seeking a reliable partner for your construction project. Here are the reasons why we believe Tri Viet Steel is an excellent choice for you:

High quality: Tri Viet Steel is committed to providing you with top-quality Pre-engineered steel buildings on the market. We use modern technology and strict quality standards to ensure that your project performs optimally and has a long lifespan.

Experience and professionalism: Experience and professionalism: With years of experience in the Pre-engineered steel building construction industry, our expert team has completed numerous large-scale projects nationwide. We understand how to coordinate and execute every task professionally and efficiently.

Convenience and time savings: Pre-engineered steel buildings from Tri Viet Steel are manufactured in factories, reducing on-site construction time. This not only saves time but also reduces costs and risks during construction.

Excellent customer service: We always listen and respond to every customer’s requirements quickly and effectively. We commit to partnering with you from the design stage to project completion to ensure your satisfaction with the final result.

English

English Tiếng Việt

Tiếng Việt