PREFABRICATED FACTORY CONSTRUCTION TO MEET PRODUCTION DEMANDS

Prefabricated factory building construction is becoming a popular choice for many businesses looking to expand their production scale or construct new factory facilities. With its convenience and efficiency, Prefabricated factory construction has gained favor among investors. However, to ensure that the project meets production requirements, attention to various essential factors is crucial.

1. What is a Prefabricated Factory Building?

Prefabricated factory buildings are structures manufactured and assembled in a factory or construction site before being transported and installed at the final location. These buildings are typically designed and produced according to the specific requirements of the client, including size, interior and exterior design, and other amenities.

2. Benefits of Prefabricated Factory Buildings

- Time Savings: Compared to traditional construction, Prefabricated Factory buildings significantly reduce construction time, allowing you to start using the facility sooner.

- Cost Savings: By using prefab components, you can save on transportation costs and optimize resource utilization.

- Stability and Reliability: Prefabricated Factory buildings are manufactured in a strictly controlled environment, ensuring uniformity and the quality of the final product.

3. Why Choose Prefabricated Factory Building Construction Services?

To ensure the success of a Prefabricated Factory building project, it’s essential to seek professional construction services. Companies specializing in Prefabricated Factory construction have experience and a deep understanding of the process and critical factors involved in building these structures.

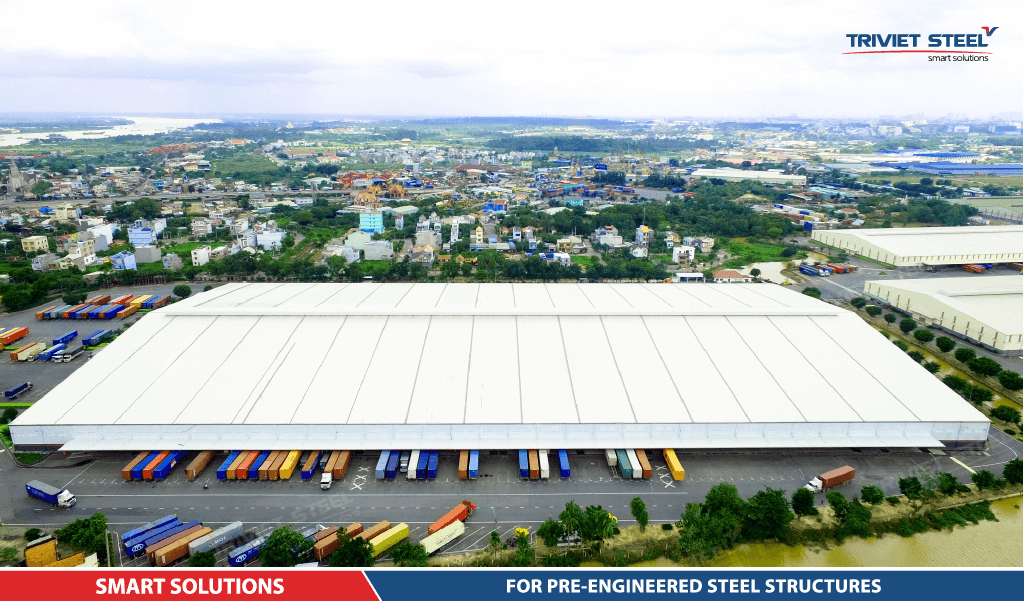

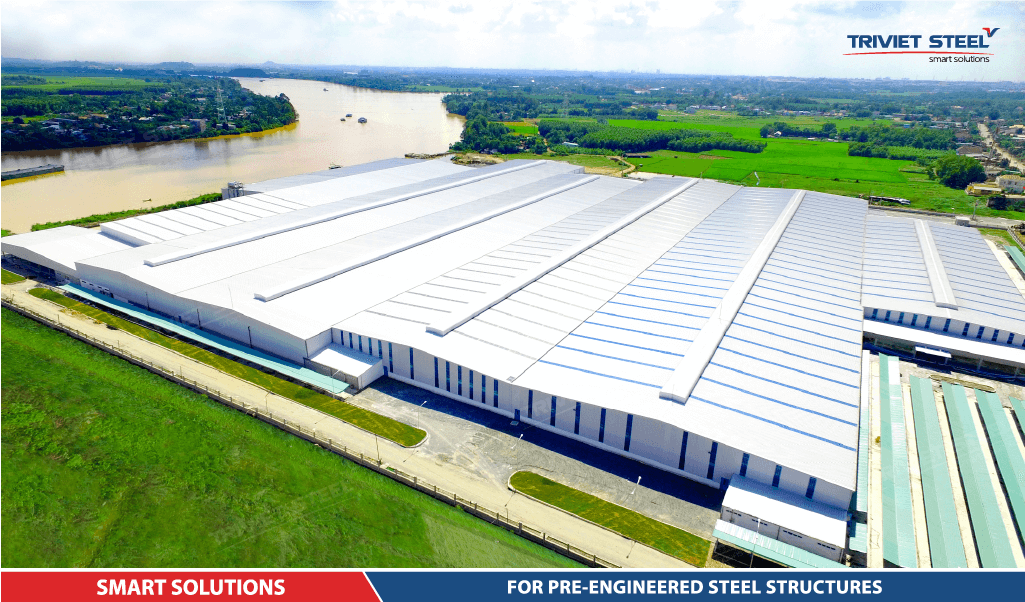

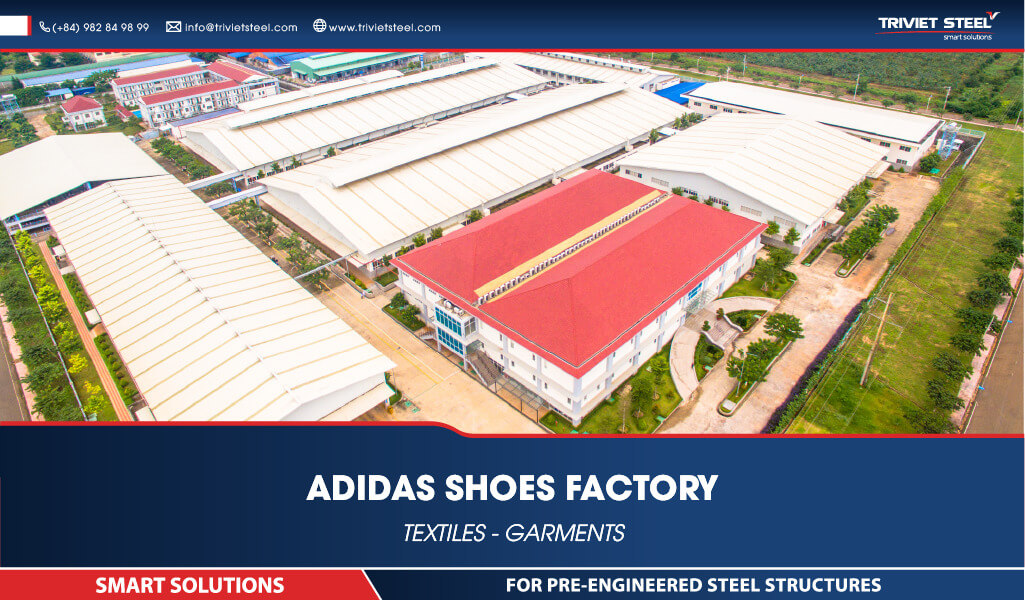

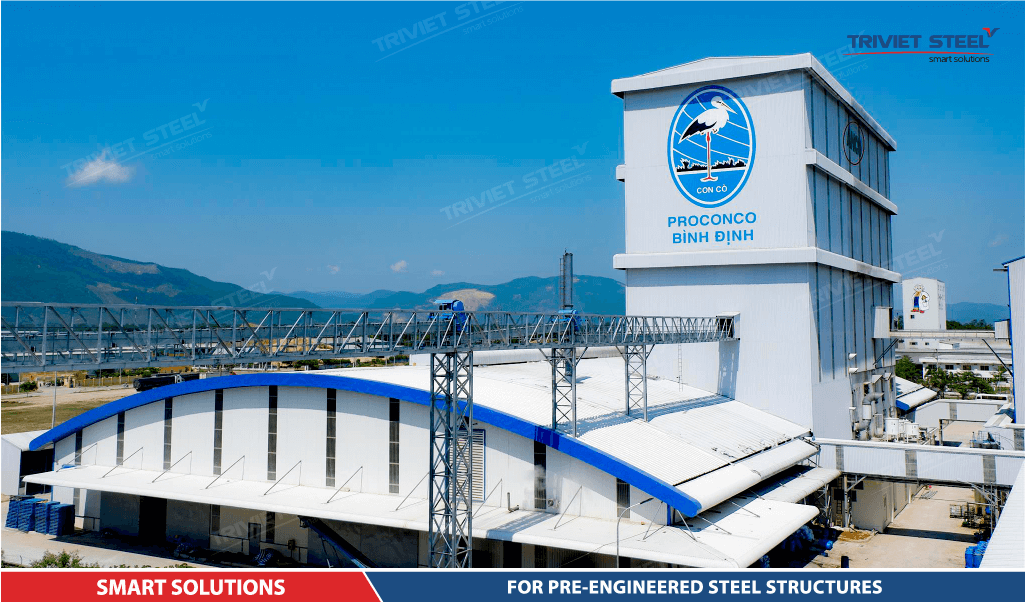

Tri Viet Steel is one of the leading reputable companies for Prefabricated factory construction in Vietnam. With nearly 20 years of experience in this field, Tri Viet Steel has successfully completed numerous Prefabricated factory projects for both large and small businesses nationwide.

4. Prefabricated Factory Construction To Meet Production Demands

4.1. Choosing the Right Location

Selecting an appropriate location is crucial, including determining the site’s position, size, and the surrounding environment. Ensure the chosen location meets infrastructure, transportation, and worker safety requirements.

4.2. Designing According to Production Needs

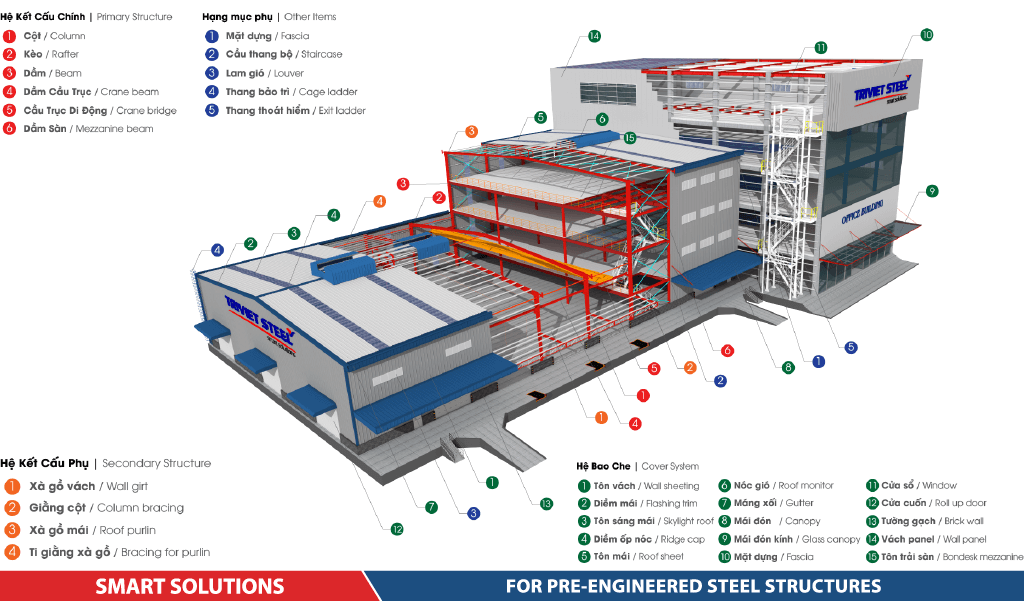

An important step is designing the factory to match your production scale, workflow, and specific industry requirements. The design must ensure efficient space utilization and meet all production needs.

- Factory Usage: Factories serve various purposes, such as manufacturing or warehousing, each with specific design requirements.

- Factory Size: The size should match the land area and usage requirements. Steel Structure: The steel structure must provide strength and durability.

- Roof, Walls, Doors: Roof, walls, and doors should be weather-resistant, heat-insulated, and soundproof.

- Electrical and Plumbing Systems: These systems must be safe and meet usage requirements.

4.3. Choosing a Reliable Construction Partner

Selecting a reputable and experienced partner is essential to ensure construction quality and project performance. This involves reviewing their previous project portfolios, assessing their workforce, and ensuring they comply with safety standards.

4.4. Using Quality Materials

Using quality construction materials is a critical factor. The quality of materials affects the durability, soundproofing, and insulation of the factory.

4.5. Adhering to Safety and Environmental Standards

Lastly, ensure that the construction process complies with all safety and environmental standards. This is particularly important in industries like manufacturing and processing, where safety is a top priority.

5. Standardized Prefabricated Factory Construction Process:

Design – Manufacturing – Installation are the 3 main stages in Prefabricated Factory building construction:

1. Design

The design stage plays a crucial role in ensuring the accuracy of dimensions, quantities, and technical requirements. Errors in the design can affect the quality of the project.

- Survey the location, layout, and provide design solutions for the client, offering optimal recommendations.

- Prepare the design construction documentation: architectural drawings, manufacturing details, and estimated design costs.

2. Manufacturing of Steel Components

The manufacturing process of steel components is carried out in a factory using modern machinery and quality control. It involves several steps:

- Receive raw materials and supplies

- Cut steel

- Press and shape components

- Welding and assembling components

- Adjust components

- Complete welding

- Clean the surface

- Paint

- Inspect and store.

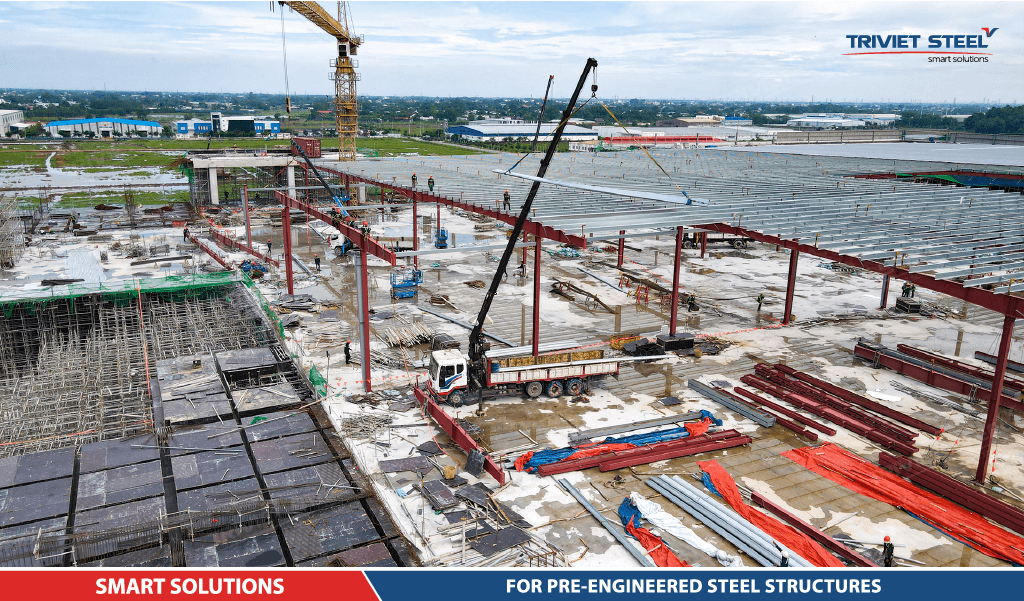

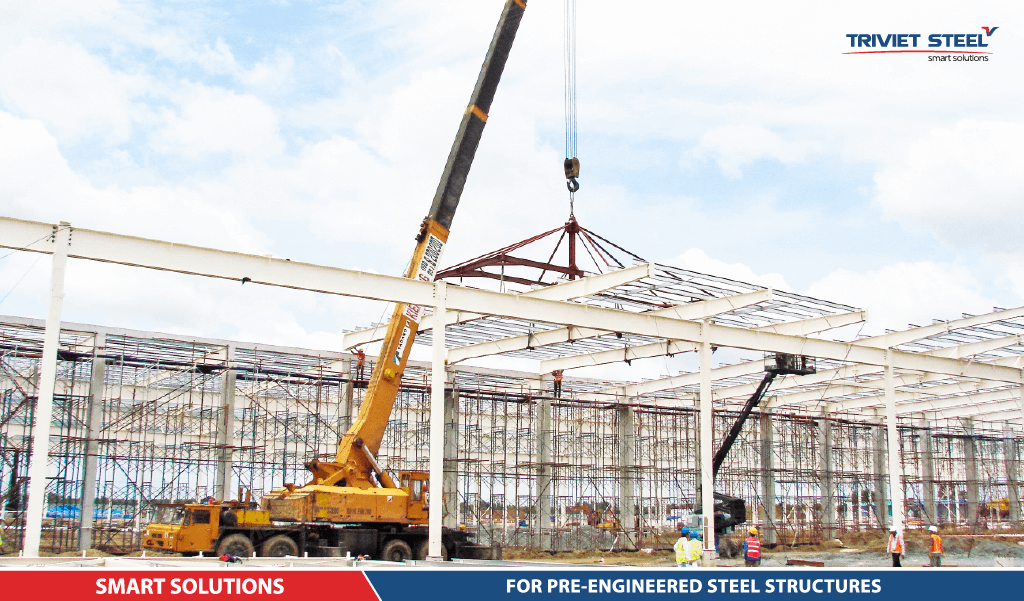

3. Prefabricated Factory Installation

During the construction phase, there will be close coordination among the various departments and divisions of the company to ensure the timely completion of the project. The Progress Supervisor will provide regular updates and reports, along with contingency plans, to ensure adherence to the contract schedule.

A significant investment has been made in safety equipment, and occupational safety monitoring is consistently updated and maintained across all steel structure construction sites.

Key Steps in the Construction Process Include:

- Receiving and storing construction materials

- Installing anchor bolts

- Assembling the main frame

- Roof installation

- Wall panel installation

- Completing the project

6. Recommendations for Customizing Prefabricated Factory Construction to Match Production Needs

6.1. For Small-Scale Manufacturing Businesses

Businesses can choose a single-story factory option. This option has a low investment cost, making it suitable for businesses with limited capital.

6.2. For large-scale manufacturing businesses

Businesses can choose a multi-story factory option. This option helps businesses save land area, making it suitable for businesses with large production needs.

6.3. For manufacturing businesses with high load requirements:

Businesses need to use steel materials with high thickness and strength to ensure the bearing capacity of the factory

6.4. For manufacturing businesses with high environmental requirements:

Businesses need to choose insulation and heat-resistant materials to ensure good working conditions for workers.

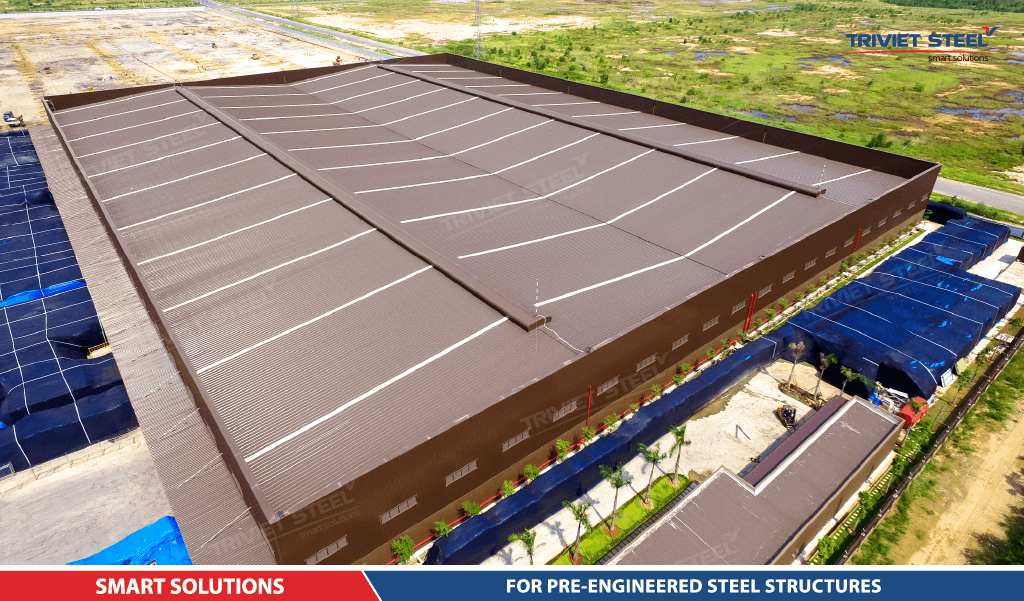

7. Tri Viet Steel – A Trusted Prefabricated Factory Construction Company

Tri Viet Steel boasts a team of skilled engineers and experienced workers. The company employs modern and advanced machinery and equipment to ensure project quality. Tri Viet Steel is committed to delivering high-quality Prefabricated factory buildings at competitive prices.

Some Advantages of Prefabricated factory Buildings Constructed by Tri Viet Steel Include:

- Rapid Construction: Tri Viet Steel completes Prefabricated factory buildings in just 30-45 days.

- Low Initial Investment: Prefabricated factory buildings are more cost-effective compared to traditional concrete and steel buildings.

- High Load Capacity: These buildings can withstand heavy loads, ideal for industries with high load requirements.

- Flexible Expansion: Prefabricated factory buildings can be easily expanded or upgraded when needed.

English

English Tiếng Việt

Tiếng Việt