STEEL STRUCTURE INTRODUCTION

The steel structure is the most ideal solution for construction projects that want to optimize cost-effectiveness because of its flexible and durable features. Learn about steel structure introduction with Triviet Steel Buildings

What is structural steel?

Structural steel is a structure made up of steel structures linked together to be able to transmit and bear the building load. Because of the steel structure, this type of construction is very sturdy and has high bearing capacity. Using less materials than other types of construction such as concrete, wood

Currently, modern constructions such as: industrial factories, commercial centers, heavy industrial plants, office buildings, stadiums, and traffic infrastructure works mostly use steel structures. for construction.

Learn more: WHY SHOULD CHOOSE STEEL FRAME STRUCTURES WHEN BUILDING AN INDUSTRIAL FACTORY?

Steel structure introduction

The steel structure will be manufactured and fabricated with specific chemical compositions, shapes, and standards according to the technical requirements of each work and project. Typical and common shapes of steel structures are:

- I-Beam

Has an I-shaped cross section, widely used in the construction of pre-engineered steel buildings, steel structure workshops because of its solid structure, good bearing capacity.

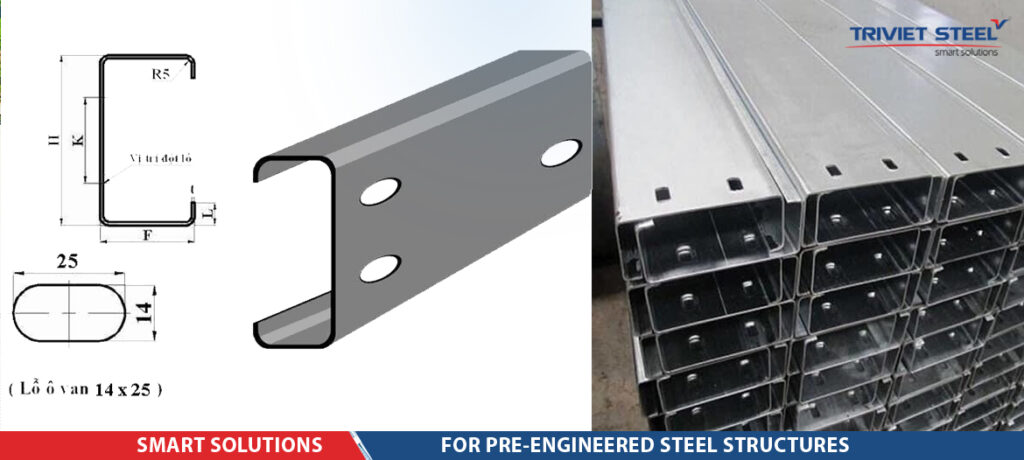

- C-shaped steel (also known as C purlin):

C purlins usually have 2 main types: galvanized purlins (preferred materials) and black purlins, products with many different specifications depending on the needs of each project. It is the main component used for steel truss frame of factory buildings.

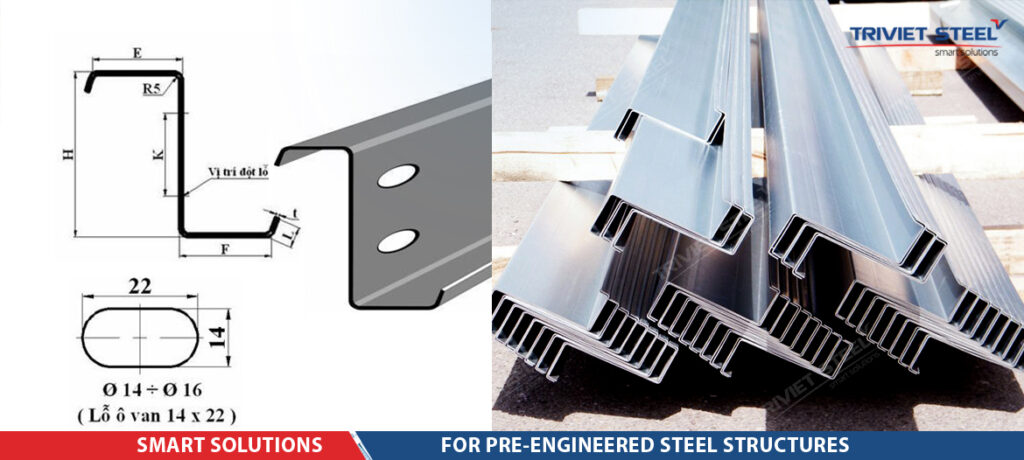

- Z-shaped steel (Z purlin):

Z purlins have extremely high bearing capacity, they can be stacked on top of each other to form continuous beams with large loads. Z purlins are often used for factory buildings with large column steps because they can be overlapped. Increase the bearing capacity and reduce the deflection of the purlin.

Various sizes and lengths of Z purlins are suitable for all construction structures.

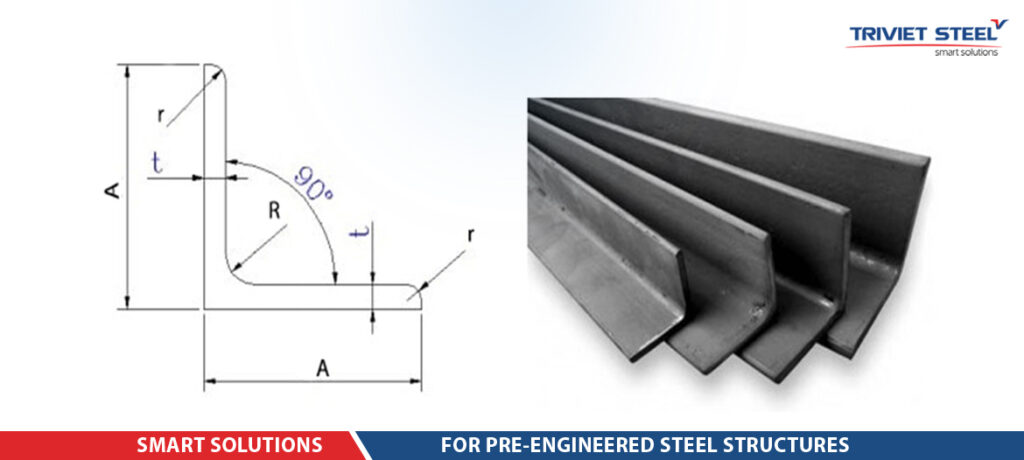

- Angle Steel

As a steel with an L-shaped cross section, the outstanding feature is very high hardness and durability, so it has a large bearing capacity. Resistant to strong vibrations and adverse effects of weather and chemicals.

Hot-dip galvanized L-shaped steel also has very good resistance to rust and corrosion. This is the highlight of this steel. Due to its ability to withstand gravity and extreme weather, this steel is used in many different sections of the building.

- Tee bar (T-shaped steel structure)

Has a T-shaped cross-section. The most common application is to make steel bars connecting between I-shaped steel bars or other shapes. Good bearing capacity, able to bend L-shaped steel due to the depth and symmetry of the steel.

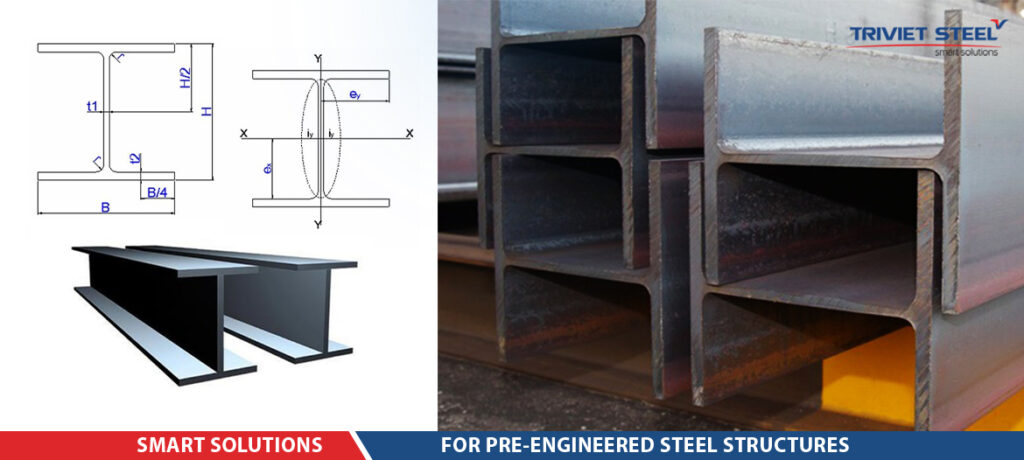

- H-beam

The steel is designed in the shape of an H-shape, very sturdy and has great bearing capacity. Ability to balance and eat whole in the structure of the building.

H-shaped steel is very diverse in weight, size and thickness. Specifications of each type are suitable for different projects and works. Often used as trusses, frames of prefabricated house structures.

- HSS (High Speed Steel)

HSS steel bar or HSS steel bar is a high-speed fast-cutting steel with high hardness and resistance to high temperatures. There are cross-section, hollow section, tubular. The shapes of HSS steel can be square, rectangular…

HSS steel bars are often used as cutting tools such as metal drill bits, welded steel frames

- Ray

Has high hardness, good crack resistance. Often used as guide rails for cranes of factories, railway installations, transport rails in factories, mining areas…

Types of common steel frame structure

- Frame structure: Beam and column

- Grid or dome structures

- Girder bridge

- Cable-stayed bridge

- Prestressed structure

- Truss structure: bar or truss

- Suspension bridge

- Truss bridge

- Arch bridge, arch architecture

- Truss bridge: truss structure

Installation of steel structure

After agreeing on technical drawings, steel structures are manufactured at the factory. Through the quality control process, it will be transported to the site for installation. The basic steps to install steel structure are as follows:

- Gathering materials and components

- Installation of bolts

- Preparation for erection: check equipment, erection materials, safety….

- Column erection

- Erection of rafter

- Erection of purlins, bracing system

- Adjust the frame of the first house

- Installation of cover system: corrugated iron roofing, drainage system and finishing

The above article has shown steel structure introduction, providing customers with necessary information about the type of construction work from structural steelTriviet Steel Buildings specializes in providing package solutions: Design – Manufacturing – Installation of pre-engineered steel buildings and steel structures with the following criteria: Quality – Safety – Aesthetics

For any information, please contact us immediately for quick support and advice:

Hotline: (+84) 982 849 889 – Email: info@trivietsteel.com

English

English Tiếng Việt

Tiếng Việt