PRE-ENGINEERED STEEL BUILDINGS DESIGN – PROCESS & CONSIDERATIONS

This article will introduce the pre-engineered steel buildings design process and things to consider when implementing it. In addition, we will also learn about the concept of pre-engineered steel buildings, the structure of steel buildings, and about Tri Viet Steel Buildings Company – one of the companies with many years of experience in this field.

1. Introduction to Pre-Engineered Steel Buildings

1.1. What is Pre-Engineered Steel Building ?

Steel components make up pre-engineered steel buildings. They are designed and manufactured with precise quantities and detailed dimensions according to the technical drawings at the factory, and then they transport them to the site for the installation and completion stage.

When installing, connect the components to each other using bolts. Thus, we can understand that the process of making a finished product (including combined inspection and quality control steps) of pre-engineered steel buildings goes through three main steps: Design – Manufacturing – Installation.

1.2. Structure of Pre-Engineered Steel Buildings

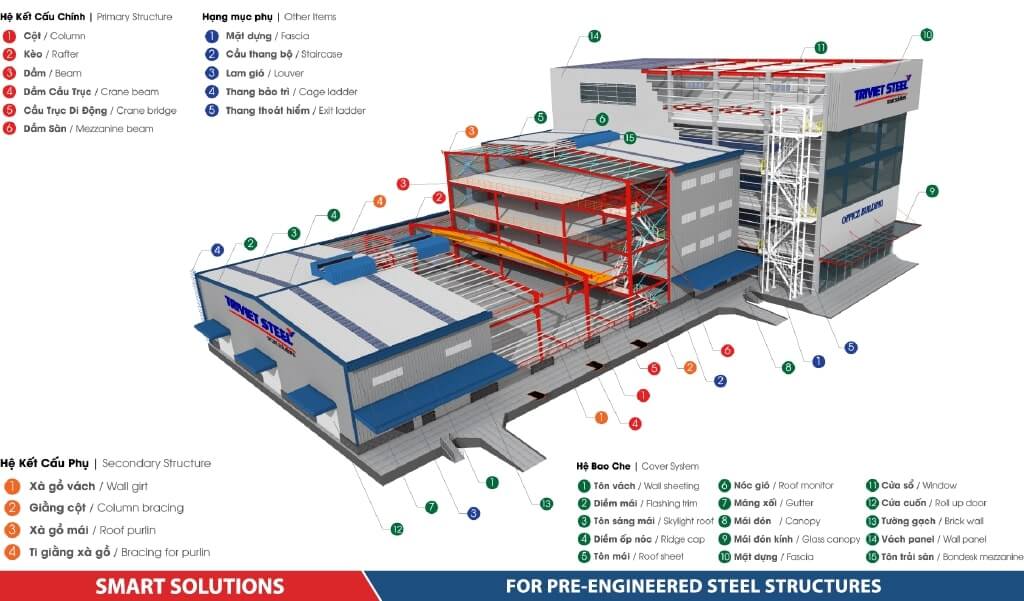

The structure of pre-engineered steel buildings includes the following main components:

- Main frame: It is the system of columns, beams, trusses, etc. that bear the main load of the structure.

- Secondary frame: It is the system of braces, purlins, etc. used to reinforce the strength of the main frame.

- Columns: They are the main load-bearing components of pre-engineered steel buildings, usually made of I-beams, H-beams, etc.

- Beams: They are the secondary load-bearing components of pre-engineered steel buildings, usually made of I-beams, H-beams, etc.

- Trusses: They are the secondary load-bearing components of pre-engineered steel buildings, usually made of I-beams, H-beams, etc.

- Purlins: They are the components that make up the secondary frame of pre-engineered steel buildings, usually made of C-shaped or U-shaped steel.

- Braces: They are the components that reinforce the strength of the main frame, usually made of I-beams, H-beams, etc.

1.3. Why Choose Pre-Engineered Steel Buildings ?

Pre-engineered steel buildings have many advantages over traditional buildings, such as:

- Fast construction time: Pre-engineered steel buildings undergo prefabrication at the factory, followed by transportation to the construction site for assembly in accordance with the design drawings, resulting in a rapid and cost-effective construction process.

- Good load-bearing capacity: Steel structures have high load-bearing capacity and durability, so pre-engineered steel buildings can withstand the effects of nature such as storms, wind,….

- Variety of designs and styles: Designers can create a variety of styles and designs for pre-engineered steel buildings to fulfill customer requirements.

- Easy to disassemble and move: Pre-engineered steel buildings allow for easy disassembly and relocation, enabling the reuse of components when needed.

1.4. Applications of Pre-Engineered Steel Buildings

Pre-engineered steel buildings find wide application in various fields, including:

- Residential: People use pre-engineered steel buildings for constructing houses, factories, offices, and more.

- Industrial: Industries employ pre-engineered steel buildings to create factories, warehouses, and other facilities.

- Commercial: Businesses use pre-engineered steel buildings to develop supermarkets, shopping malls, and similar structures.

- Agriculture: Farmers utilize pre-engineered steel buildings to establish greenhouses and other agricultural facilities.

2. Information about Pre-engineered Steel Buildings Design

2.1. Definition of Pre-engineered Steel Buildings Design

Pre-engineered steel buildings design is the process of creating and planning to construct a building using prefabricated steel structures and components. The goal of this design is to create a durable, quick-to-build, and responsive to the requirements of the investor.

2.2. Basic Parameters in Pre-engineered Steel Buildings Design

The basic parameters include:

- Steel weight: This is the amount of steel used in the pre-engineered steel building structure, measured in kilograms or tons.

- Dimensions and shape of steel components: Including the length, width, thickness, and shape of components such as columns, beams, and structural frames.

- Safety factor: This is an important factor to ensure the safety and durability of the structure. The safety factor is applied to calculate the load, bearing capacity, and resistance capacity of the steel structure.

- Structural standard: Structural standards such as ASTM, ISO, or other national standards are also applied in pre-engineered steel buildings design to ensure the quality and reliability of the project.

2.3. Standards and Regulations for Pre-engineered Steel Buildings Design

When designing steel buildings, it is necessary to comply with the current standards and regulations such as:

- Vietnamese standard: TCVN 5574:2012 – technical regulations on technical requirements for prefabricated steel structures. This standard includes regulations on materials, design, construction, acceptance,…..

- International standard: AISC 360-16 – technical regulations on technical requirements for steel structures. This standard is widely applied worldwide, including Vietnam.

- National technical regulation: QCVN 09:2009/BXD – technical regulations on technical requirements for prefabricated steel buildings. This standard is issued by the Ministry of Construction of Vietnam.

In addition, when designing pre-engineered steel buildings, we need to pay attention to the following regulations:

- Environmental Protection Regulations: To meet environmental protection requirements, you need to consider regulations related to the use of materials and energy conservation.

- Occupational Safety Regulations: Ensure that the design process also meets occupational safety regulations to ensure the safety of those involved in construction.

The pre-engineered steel buildings design process requires careful consideration and attention to standards and regulations. This ensures that the building is built with high quality and safety for everyone.

3. Pre-engineered Steel Buildings Design Process

3.1. Architectural Drawings from Customers

The first step in the pre-engineered steel buildings design process is to receive architectural drawings from customers.

Architectural drawings will provide basic information about the project, such as:

- Project dimensions: length, width, and height of the project.

- Number of floors: number of floors of the project.

- Function of use: function of use of the project.

- Aesthetic requirements: aesthetic requirements of the project.

3.2. Calculation – Design and Quotation

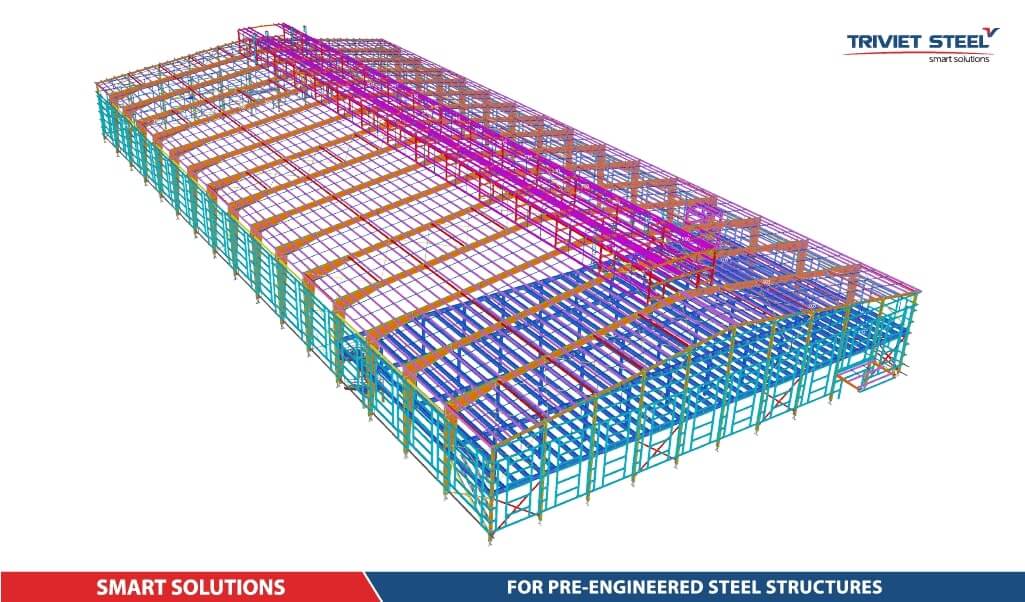

Based on the architectural drawings, the design engineer will proceed to calculate the steel structure of the project. The calculation results will be shown in the design drawings.

The design drawings will include the following information:

- Technical specifications of the steel structure: dimensions, shape, material, …..

- Plan view: shows the shape and dimensions of the rooms and areas in the project.

- Elevation view: shows the shape and dimensions of the sides of the project.

- Detailed view: shows the details of the steel structure such as welds, bolts,….

Based on the design drawings, the design company will create a quotation for the project.

3.3. Signing the Contract

After the customer agrees to the quotation, the two parties will proceed to sign a design and construction contract. The contract will clearly stipulate the rights and obligations of the two parties.

3.4. Construction Drawings

Based on the design drawings, the construction engineer will proceed to create construction drawings. Construction drawings will be used for the production and erection of the project.

3.5. Production Drawings

Based on the construction drawings, the manufacturing plant will proceed to produce the steel components of the project. The steel components will be manufactured according to the standards and technical regulations.

3.6. Erection Drawings

Based on the construction drawings, the construction team will proceed to erect the project. The project will be erected according to the drawings and technical standards.

4. Things to Consider When Designing Pre-engineered Steel Buildings

4.1. Choose a Reliable Design Firm

A reliable pre-engineered steel buildings design firm will have a team of experienced and qualified engineers and architects. They will ensure that the design drawings meet current standards and regulations, ensuring the quality and safety of the project.

4.2. Comply with Current Standards and Regulations

When designing a pre-engineered steel buildings, it is important to comply with current standards and regulations, such as:

- Vietnamese Standard: TCVN 5574:2012 – Prefabricated Steel Structures

- International Standard: AISC 360-16 – American Institute of Steel Construction

- National technical regulation: QCVN 09:2009/BXD – National technical regulation on prefabricated steel buildings

4.3. Calculate the Technical Specifications Accurately

The steel structure is the most important component of a prefabricated steel building. Therefore, it is important to accurately calculate the technical specifications of the steel structure to ensure that the building has good load-bearing capacity and high durability.

4.4. Choose High-quality Steel Materials

Steel materials are an important factor that determines the quality and lifespan of the building. Therefore, it is important to choose high-quality steel materials that meet technical standards.

4.5. Thoroughly Review the Design Drawings Before Construction

The design drawings are the basis for construction and acceptance of the project. Therefore, it is important to thoroughly review the design drawings before construction to ensure that the drawings meet current standards and regulations, ensuring the quality and safety of the project.

5. Conclusion

Thus, designing a prefabricated steel building is a challenging technical process with a variety of factors to consider. To ensure that the construction project is successfully completed and meets all requirements, businesses need to note the points that Tri Viet Steel Building has mentioned in this article.

When all of these factors are considered and taken into account during the design process, your business will have a warehouse or prefabricated steel workshop that meets all requirements, from durability, energy efficiency to aesthetics.

If you are looking for experts in the field of prefabricated steel building design and installation, please contact Tri Viet Steel Building for professional advice and support. We are always ready to ensure that your project is carried out successfully and meets all requirements.

6. Pre-engineered Steel Buildings Design Firm

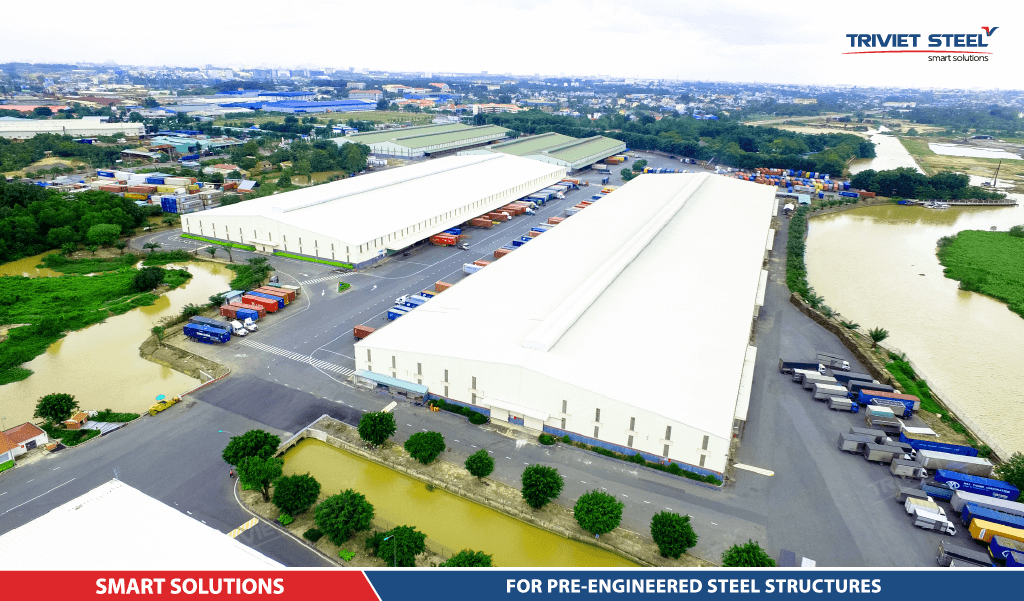

6.1. Tri Viet Steel Building – Reputable Design, Manufacturing and Installation Firm for Pre-engineered Steel Buildings

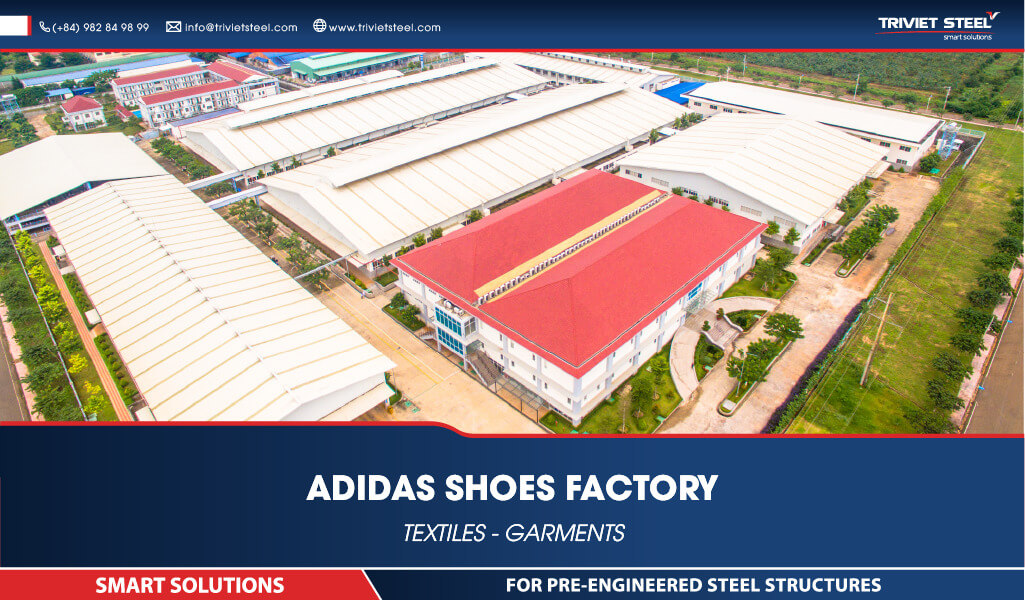

Tri Viet Steel Building is one of Vietnam’s leading firms in design, manufacturing and installation of pre-engineered steel buildings. With nearly 20 years of experience in the field. We have delivered thousands of high-quality pre-engineered steel buildings to our clients, meeting all their usage requirements.

- Comprehensive service from design to installation: Tri Viet Steel provides a comprehensive service from design, manufacturing to installation of prefabricated steel buildings. Customers only need to provide their needs and Tri Viet Steel Buildings will advise and provide the best solution.

- Professional engineers and workers: Tri Viet Steel has a team of professional engineers and workers with high skills and experience. The prefabricated steel buildings constructed by Tri Viet Steel Buildings all ensure quality, safety, and aesthetics.

- Modern technology: Tri Viet Steel has invested in a modern machinery and equipment system to produce prefabricated steel building components. This helps to ensure the quality and accuracy of the components.

6.2. Reasons to choose Tri Viet Steel Building

- High quality, ensuring safety

- Competitive price

- Professional service

- Fast construction time

- Professional team with high skills

- Modern machinery and equipment for production, meeting high standards

- One of the long-standing firms in the steel building industry

English

English Tiếng Việt

Tiếng Việt