TYPES OF OVERHEAD CRANES IN FACTORIES & INSTALLATION METHODS

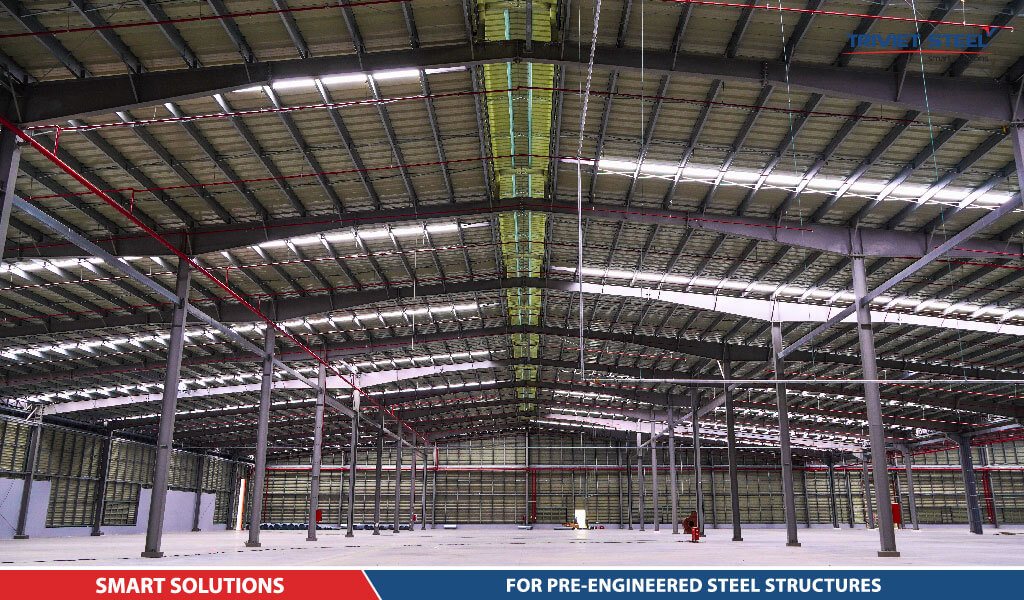

Pre-engineered steel buildings are a modern and time-saving construction solution widely used in the industry. With their convenience and high durability, pre-engineered steel buildings have become a popular choice. In this article, we will explore the types of overhead cranes in factories and their installation methods.

1. Pre-Engineered Steel Buildings: Diverse Options for Factory

1.1. What is a Pre-Engineered Steel Building ?

A pre-engineered steel building is a type of construction assembled by fitting together pre-fabricated steel components manufactured in a factory. These steel components are produced using advanced technology, ensuring precision and high quality. Moreover, a pre-engineered steel building offers numerous advantages, such as rapid construction, cost-effectiveness, and design flexibility.

1.2. Notable Features of Pre-Engineered Steel Buildings

Pre-engineered steel buildings stand out not only for reducing construction time but also for their flexibility in design. This allows for quick response to specific project requirements, particularly in constructing overhead cranes in factories.

2. Steel Structures in Pre-Engineered Steel Buildings

2.1. What are Steel Structures ?

Steel structures are the building components of pre-engineered steel buildings that are interconnected and come in various shapes and sizes. They possess remarkable characteristics such as high load-bearing capacity and resilience to harsh weather conditions. Therefore, these structures are sturdy and minimize material consumption compared to other types of structures like concrete or wood. Due to these outstanding advantages, steel structures are always a preferred choice for engineers when constructing various projects.

2.2. Common Types of Steel Structures

Steel frame structures are widely used and common in applications such as warehouses, factories, industrial plants, shopping centers, office buildings, conference centers and transportation infrastructure like airports and train stations. The following are typical types of steel structures:

- Frame structures: beams and columns

- Grid structures: arched roofs and grid-shaped structures

- Girder bridges

- Cable-stayed bridges

- Truss structures: truss members or frameworks

- Arch bridges

- Dome architecture

- Suspension bridges

- Truss girder structures

3. What is an Overhead Crane in a Factory ?

In the manufacturing environment of factories, an overhead crane plays a crucial role in the transportation and lifting of materials and products. Understanding the different types of overhead cranes and their installation procedures is essential to ensure efficiency and safety in the production process. In fact, there are several common types of overhead cranes used in factories.

An overhead crane in a factory is a heavy-duty crane system that consists of a bridge crane running on an overhead runway, combined with one or more hoists to lift and move materials or goods during the production process. The structure of an overhead crane in a factory includes the main beam, end beams, lifting mechanism, and control system.

4. Types of Overhead Cranes in Factories

In factories, various types of overhead cranes are used to meet different lifting and transportation requirements. Here are some popular types of overhead cranes:

4.1. Single Girder Overhead Crane

Furthermore, the single girder overhead crane offers excellent versatility and efficiency in handling various materials and goods. It is widely utilized in industries such as manufacturing, warehousing, and logistics due to its compact design and ease of operation. Additionally, this type of crane can be equipped with advanced safety features and remote control systems, ensuring enhanced productivity and worker safety.

- Structure: Consists of one main girder and a hoist assembly below.

- Lifting capacity: 0.5-5 tons.

- Advantages: Simple design, low cost, suitable for small factories.

- Examples: 3-ton overhead crane, 5-ton overhead crane.

4.2. Double Girder Overhead Crane

The double girder overhead crane is an upgraded version of the single girder overhead crane. It consists of two parallel running bridge cranes on the runway and two independent hoist assemblies. Double girder overhead cranes have the ability to lift and move loads more quickly and efficiently compared to single girder cranes. They are more commonly used in businesses and factories with higher lifting capacities. Double girder overhead cranes can be adjusted for speed and provide stable operation to meet the production needs of businesses.

- Structure: Consists of two main girders, two end beams, control system, lifting mechanism.

- Lifting capacity: 3-15 tons. Suitable for heavier lifting tasks than single girder cranes.

- Examples: 5-ton overhead crane, 10-ton overhead crane.

4.3. A-Frame Overhead Crane

The A-frame overhead crane, unlike other overhead cranes, is a type of crane designed in the shape of an “A.” It is characterized by a bridge crane running on an A-shaped overhead runway and a hoist assembly positioned in the middle. Therefore, A-frame overhead cranes are ideally suited for factories with limited space and require flexible movement.

- A-shaped structure, capable of 360-degree rotation.

- Lifting capacity: 5-30 tons. Suitable for narrow spaces and heavy transportation within warehouses.

- Suitable for industrial production and heavy machinery transportation.

4.4. Monorail Overhead Crane

The monorail overhead crane, operating on a single rail, stands out as a space-efficient lifting solution. This crane configuration comprises a bridge crane traversing along a horizontal rail, complemented by a hoist assembly dedicated to the seamless lifting and movement of goods. Specifically designed for confined spaces and short travel distances, monorail overhead cranes provide optimal performance in scenarios where space is at a premium, making them a versatile choice for efficient material handling in industrial environments.

- Rail mounted high on the ceiling or wall, with only one beam moving along the rail.

- Lifting capacity: 5-50 tons. Suitable for large spaces and heavy transportation across different areas.

4.5. Rotating Overhead Crane

The rotating overhead crane, renowned for its capacity to pivot around an axis, represents an innovative solution for seamless material handling. This crane configuration incorporates a bridge crane seamlessly traversing along a dedicated runway, accompanied by a highly adaptable hoist assembly capable of independent rotation around its axis. Specifically designed to excel in lifting and transporting goods within expansive spaces, rotating overhead cranes are essential for operations demanding not only strength but also unparalleled flexibility in movement. This makes them a preferred choice for efficiently managing material handling challenges in large industrial settings.

- Capable of 360-degree rotation around the crane post to access all directions.

- Lifting capacity: 10-100 tons. Suitable for tasks that require multi-point access.

5. Installation of Overhead Cranes for Warehouse Safety

Ensuring the safe and effective installation of workshop overhead cranes involves following specific steps:

5.1. Basic Preparation

Before starting the installation, accurately determine the positioning of the overhead crane within the warehouse. Ensure that the warehouse floor is sufficiently sturdy to support the crane’s load. If necessary, reinforce the floor.

5.2. Installation of End Beams

To start the installation process, first, carefully position the two end beams on both ends of the main beam. These end beams are vital as they not only provide cushioning but also serve as the crane’s final stopping point. For a secure and safe installation, utilize bolts, screws, and connecting accessories.

5.3. Installation of Remaining Components

Install other components such as auxiliary beams, crossbars, and guardrails. These components provide support and protection for the overhead crane. Use bolts, screws, and connecting accessories to ensure their tight installation onto the main beam.

5.4. Lifting the Crane onto the Rails

Use two appropriately rated cranes to lift the overhead crane onto the rails. Take careful consideration of aligning and balancing the crane to avoid any misalignment or damage during operation.

5.5. Hoisting the Crane Cabin

To commence the installation, carefully hoist the crane cabin into position using durable steel cables and reliable suspension hooks. The crane cabin, which typically encompasses the control system and operator cabin, is vital for seamless remote or on-site crane control. Prioritize a balanced and secure hoisting process to guarantee optimal safety and functionality. Moreover, ensure proper alignment of the cabin with the main beam to facilitate efficient operation.

5.6. Crane and Hoist Installation

Install the crane and hoist onto the main beam using steel cables and suspension hooks. The hoist plays a vital role in lifting and lowering the goods. Additionally, connect the hoist to the electrical system and controls of the crane. It is crucial to ensure proper and safe installation. For more detailed guidance and in-depth insights, please continue reading the following instructions

5.7. Installation of Electrical Cable and Lifting Mechanism

Install the overhead crane’s electrical cable system to provide power to the crane and other devices. Subsequently, install the lifting mechanism, incorporating essential components such as steel cables, pulleys, gears, and motors. This comprehensive setup ensures not only the provision of power but also safe and efficient lifting and lowering of goods. For a more detailed and step-by-step guide, please refer to the following instructions

5.8. Electrical and Control System Installation

Install the electrical system, encompassing the wiring from the power source to the control panel and operator cabin. Utilize conduit pipes, wiring, and connecting accessories for a robust setup that not only ensures safe installation but also facilitates ease of maintenance. To delve into a more detailed and systematic installation process, please proceed to the following comprehensive guidelines

5.9. Inspection and Maintenance

After completing the installation, it is imperative to conduct thorough inspections to guarantee the safety and effectiveness of the overhead crane. Carefully check the bolt connections, screws, and connecting accessories for any signs of discrepancies. Additionally, inspect the electrical system, cables, control panel, and operator cabin to ensure optimal functionality. Verify the performance of critical components such as the hoist, trolley, control system, and cabin. Furthermore, conduct a comprehensive examination of the lifting mechanism, including steel cables, pulleys, gears, motors, and other crane components. This meticulous inspection process aims to ensure that all equipment operates robustly and safely. For a more detailed checklist and inspection guidelines, please refer to the following comprehensive instructions

5.10. Training and Instruction for Warehouse Crane Operations

Lastly, provide training and instructions to the crane operators. They should be familiar with the operation of control devices, safety procedures, and regular maintenance measures. Training ensures that the overhead crane is operated safely and efficiently throughout its service life.

6. Conclusion:

Understanding the different types of overhead cranes and following professional installation procedures not only optimizes production efficiency but also ensures safety and sustainability for industrial warehouses. For any business, investing in the right overhead crane and implementing proper installation processes is key to optimizing operations and reducing maintenance costs in the long term.

Installation Notes for Warehouse Overhead Cranes:

- Install overhead cranes according to the approved design, ensuring safety and efficiency.

- Construct the workshop frame securely to support the overhead crane load.

- Install rails accurately, ensuring flatness and rigidity.

- Properly install main beams, end beams, trolleys, and hanging hooks to ensure safety during material handling.

- Electrical and control systems must be installed following technical standards for safe crane operation.

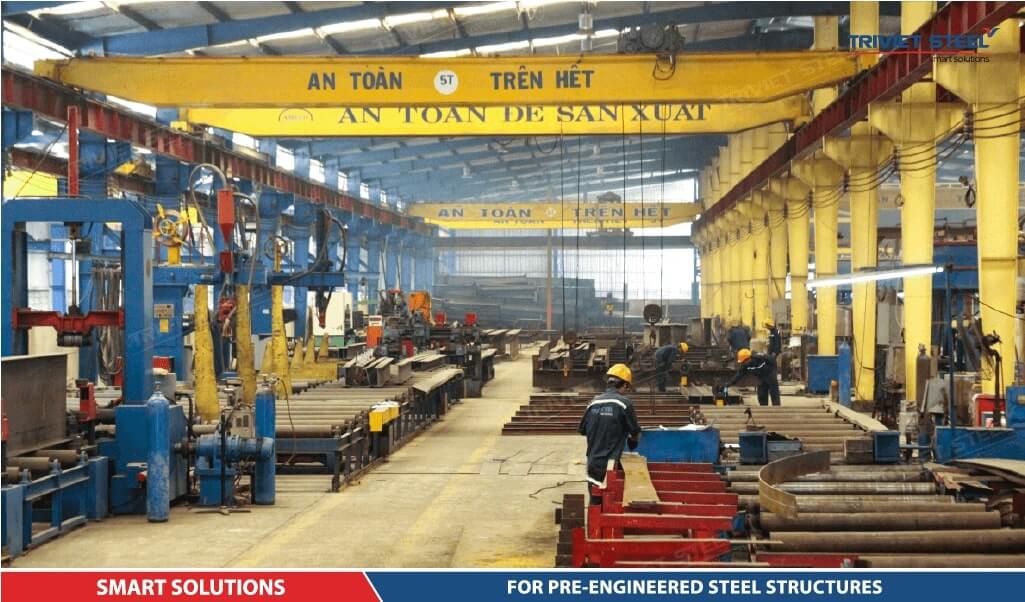

7. Tri Viet Steel Buildings – Smart Solutions for Pre-Engineered Steel Buildings

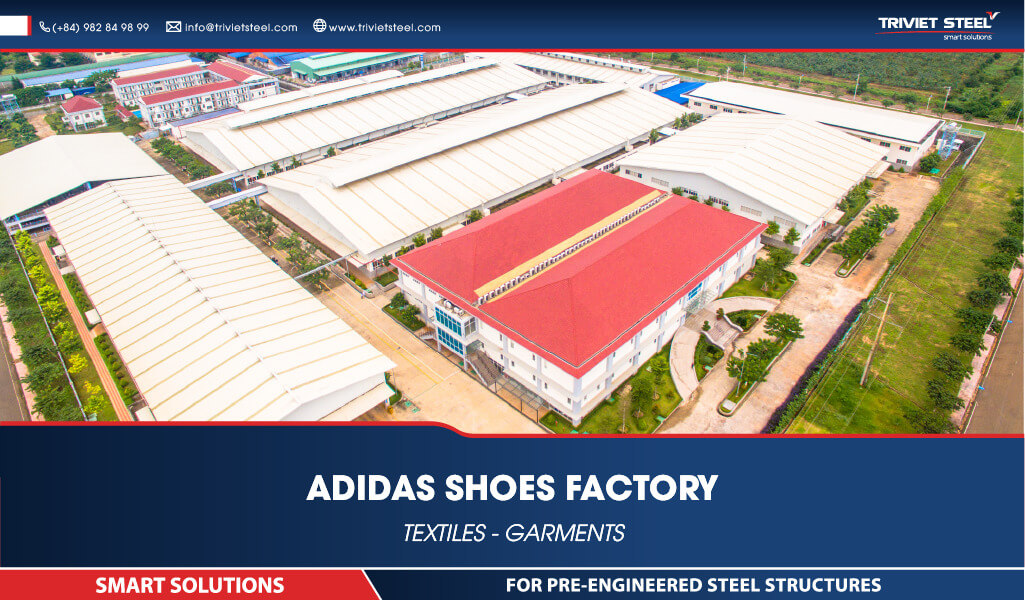

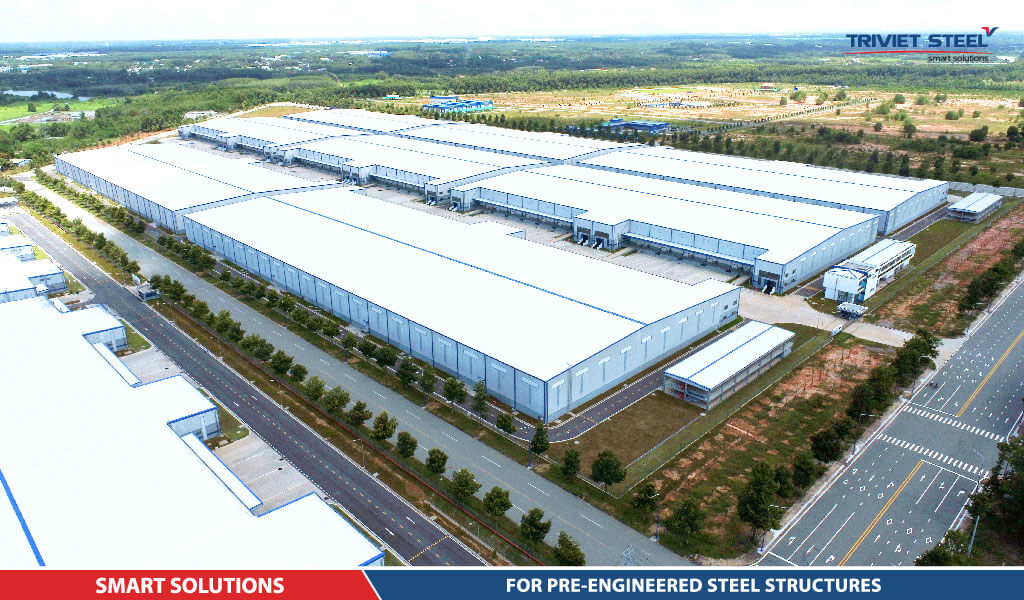

Tri Viet Steel Buildings is a leading company in pre-engineered steel buildings construction in Vietnam. With 19 years of experience, Tri Viet Steel Buildings has successfully completed thousands of pre-engineered steel building projects nationwide, ranging from residential homes and workshops to public, commercial, and industrial structures.

Tri Viet Steel Buildings continuously strives to provide customers with intelligent, high-quality, and competitively priced pre-engineered steel buildings solutions. With a team of experienced engineers and architects, Tri Viet Steel Buildings can meet all customer needs, from simple to complex requirements.

English

English Tiếng Việt

Tiếng Việt