4 KEY CONSIDERATIONS IN DESIGNING STRUCTURAL STEEL DRAWINGS

Structural steel pre-engineered buildings have become a current trend in construction. Every pre-engineered steel workshop or building requires a complete and detailed structural steel drawing. So, how many types of drawings are there, and what should be considered when designing structural steel drawings?

1. What is a Structural Steel Drawing ?

A structural steel drawing is a technical plan that outlines the construction details of buildings, factories, and industrial workshops. It serves as a roadmap, providing guidance for the construction processes. Typically, architectural drawings are prepared prior to structural steel drawings. However, in certain cases, structural steel drawings are developed based on existing architectural drawings.

A structural steel drawing, also known as a blueprint, depicts the connections of steel materials utilized in construction. It serves as a comprehensive guide for contractors in selecting, ordering, and assembling construction materials. Essentially, a structural steel drawing illustrates the positions, dimensions, and specifications of each type of structural steel material employed in the project, ensuring precise coordination and alignment during the construction process. With the detailed information provided in the drawing, contractors can accurately estimate material quantities, plan for efficient construction sequences, and ensure the structural integrity and safety of the final structure.

The main components of a structural steel drawing include:

- Building height: This shows the exterior walls of the building.

- Structural layout: The layout diagram shows the positions of floors, foundations, and roofs of the building. This section may also indicate where structural elements are located.

- Contractor’s construction ideas: This section depends on the requirements of the contractor that the construction designer and builder implement.

2. Types of Structural Steel Drawings

Common types of structural steel drawings for steel structures include:

- Foundation drawings: These drawings present specifications for foundation details, thickness, length, and construction options for the workshop.

- Column positioning drawings: These drawings present the shape, dimensions, and precise positioning of columns.

- Steel floor plan drawings: These provide detailed descriptions of the steel layout positions for the workshop floor.

- Structural elevation drawings: These drawings show important data regarding the floor structure, beam structure, positions, heights, thicknesses, etc.

Required drawings in the construction drawing of a structural steel project:

- Foundation design drawings

- Sketch design drawings

- Construction design drawings

- Shop drawings

3. Top 4 Key Considerations in Designing Structural Steel Drawings

To ensure the quality of the completed project, the design drawings must accurately and clearly depict the details. Therefore, the following 4 considerations should be kept in mind to avoid errors during the design process:

3.1. Accuracy and Clarity

The designers must present the design drawings with precision and clarity, leaving no room for misinterpretation. Additionally, they should include clear labels, dimensions, and annotations to facilitate understanding and implementation

3.2. Compliance with Codes and Standards

In addition, structural steel drawings must adhere to applicable building codes and industry standards. This ensures that the design meets safety and regulatory requirements

3.3. Material Selection and Specifications

Moreover, the choice of steel materials and their specifications should be clearly indicated in the drawings. This includes specifying the grade of steel, dimensions, and any special requirements for fabrication and construction.

3.4. Coordination with Other Disciplines

Structural steel drawings should be coordinated with other disciplines, such as architectural and mechanical drawings. This ensures that all elements of the project work together seamlessly and avoids conflicts during construction.

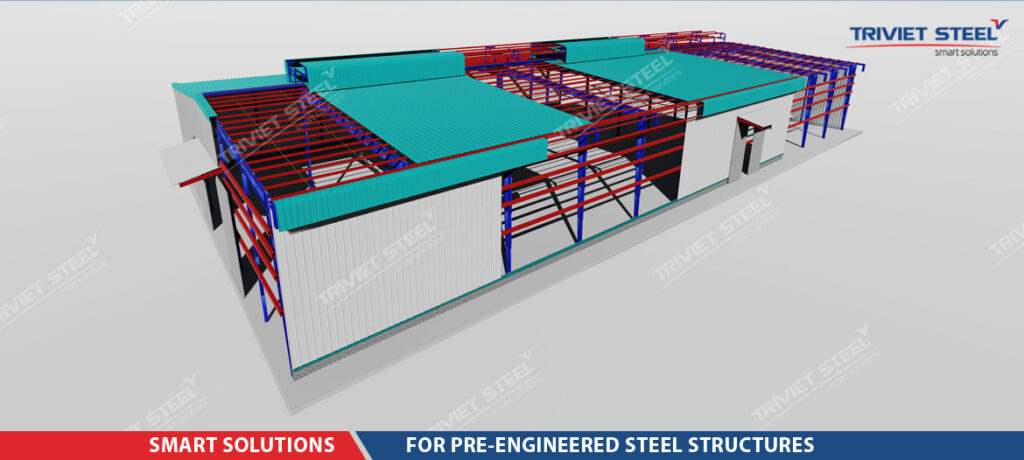

4. Tri Viet Steel Buildings – Smart Solutions for Pre-Engineered Steel Buildings

Tri Viet Steel Buildings, being a premier company in the domain of pre-engineered steel building construction in Vietnam, has garnered extensive expertise over the course of 19 years. Through their unwavering commitment to excellence, Tri Viet Steel Buildings has accomplished an impressive portfolio of thousands of pre-engineered steel building projects all across the nation. These projects encompass a diverse range of structures, including residential homes, workshops, as well as public, commercial, and industrial edifices. By virtue of their unrivaled industry knowledge, Tri Viet Steel Buildings has emerged as a trusted name in the realm of pre-engineered steel construction in Vietnam.

English

English Tiếng Việt

Tiếng Việt