FIRE PREVENTION AND FIRE FIGHTING SYSTEM FOR PRE-ENGINEERED STEEL BUILDINGS

In the 21st century, pre-engineered steel buildings have become not only a trend but also a practical and sustainable construction solution. However, to ensure the safety of these structures, compliance with Fire Prevention and Fire Fighting (FPFF) standards is essential. In this article, we will explore the standards of Fire Prevention and Fire Fighting (FPFF) for Pre-engineered Steel Buildings, highlighting the requirements and regulations that individuals must follow to ensure safety.

1. Introduction to Pre-engineered Steel Buildings

1.1. What are Pre-engineered Steel Buildings (PEBs) ?

Pre-engineered steel buildings (PEBs) are considered one of the most advanced and modern construction technologies utilized globally. By integrating steel structures with pre-manufactured building components, PEBs provide numerous advantages for construction projects, resulting in time, labor, and resource savings.

In addition to their cost-efficiency, PEBs exhibit remarkable versatility, rendering them suitable for various types of structures. Whether residential houses, warehouses, or industrial and commercial buildings, individuals can tailor the components of PEBs to meet specific project requirements. This flexibility allows for customized design and seamless installation, optimizing both space arrangement and structural efficiency.

1.2. Structure of Pre-engineered Steel Buildings

The structure consists of three main components:

- Structural framework: a combination of columns, steel trusses, beams,….

- Substructure: Z-shaped, C-shaped, and U-shaped purlins, wall bracing, wall studs, and other components.

- Enclosure system and accessories such as roof panels, wall panels,…..

Additionally, to meet the needs of investors and customers, the designs of pre-engineered buildings can incorporate additional structures such as:

- Mezzanine floors, overhead crane beams (to support crane systems), roof support systems, walkways,….

- Detailed accessories: canopies, extensions, fascia, downspouts, ridge caps, ventilation systems, bracing cables,….

1.3. Why Choose Pre-engineered Steel Buildings ?

- Cost-saving: Optimize construction material and labor costs by implementing efficient strategies.

- Versatility: Users can combine pre-engineered steel buildings with other structures and accessories such as overhead crane beams, mezzanine floors, operational walkways, fascia, partition walls, etc., making them suitable for various purposes.

- Fast construction and erection time: The design, manufacturing, and processing of steel components take place at the factory, and they are later transported to the construction site for installation. This construction method is highly scalable and can accommodate additional functions based on diverse requirements from investors and customers.

- Excellent moisture and mold resistance: Pre-engineered steel buildings are designed with high-quality waterproof materials and vertical roof connections, including ridge caps, to ensure effective water drainage and prevent moisture and mold issues.

- Environmental friendliness: Pre-engineered steel buildings have lightweight structures and components made from recyclable materials, resulting in reduced construction waste. These buildings also have a lifespan of over 100 years, contributing to long-term sustainability.

2. FPFF Standards for Pre-engineered Steel Buildings

Pre-engineered steel buildings (PEBs) are constructed using pre-manufactured steel structures assembled on-site. This type of construction offers advantages such as fast construction time, low cost, and high durability. However, pre-engineered steel buildings are more susceptible to fire hazards compared to other types of structures. Therefore, ensuring Fire Prevention and Fire Fighting (FPFF) safety for pre-engineered steel buildings is crucial.

2.1. General Regulations for FPFF in Pre-Engineered Steel Buildings in Vietnam:

The following legal documents stipulate the general regulations for Fire Prevention and Fire Fighting (FPFF) in pre-engineered steel buildings in Vietnam:

- Fire Prevention and Fire Fighting Law 2001

- Decree No. 79/2014/ND-CP dated July 31, 2014, of the Government, detailing the implementation of the Fire Prevention and Fire Fighting Law

- Circular No. 64/2014/TT-BCA dated November 15, 2014, of the Ministry of Public Security, regulating the approval of designs and acceptance of fire prevention and fire fighting for construction projects

According to these regulations, PEBs in Vietnam must meet the following FPFF requirements:

- Have fire prevention and fire fighting designs that comply with technical standards

- Have a fire alarm and fire fighting system installed and regularly operated to ensure effective operation

- Have an approved fire prevention and fire fighting plan

- Have an organized fire prevention and fire fighting force, trained personnel, equipped with fire fighting vehicles and tools as required

2.2. Specific FPFF Requirements for Pre-Engineered Steel Buildings in Vietnam:

The following technical standards stipulate the specific Fire Prevention and Fire Fighting (FPFF) requirements for pre-engineered steel buildings (PEBs) in Vietnam:

- TCVN 2622-1995: “Fire Prevention and Fire Fighting for Buildings – Design Requirements”

- TCVN 5738-2001: “Fire Alarm Systems – Technical Requirements”

- TCVN 5760-2001: “Fire Fighting Systems – General Requirements for Design, Installation, and Use”

- TCVN 6379:1998: “Fire Fighting Equipment – Fire Hydrant – Technical Requirements”

- TCVN 4513-88: “Internal Water Supply – Design Standards”

- TCVN 3256-89: “Fire Safety – General Requirements”

- TCVN 3890-2009: “Fire Prevention and Fire Fighting Equipment for Buildings and Structures – Equipment, Layout, Inspection, and Maintenance”

- TCVN 5684:2003: “Fire Safety for Oil and Petroleum Facilities – General Requirements”

- TCVN 4879:1989: “Fire Protection – Safety Signs”

- TCVN 48:1996: “Fire Prevention and Fire Fighting for Commercial Enterprises and Service Providers – General Regulations”

Vietnamese Standards:

- QCVN 06-2020/BXD: “National Technical Standards for Fire Safety in Buildings and Structures”

- QCVN 08: 2009/BXD: “National Technical Standards for Underground Urban Structures”

According to these standards, PEBs must fulfill the following FPFF requirements:

- Steel structures must be fire-resistant, with a minimum fire resistance rating of 120 minutes.

- Entrances and windows should be made of non-combustible or fire-resistant materials.

- The FPFF system must include the following components:Automatic fire alarm system

- Automatic fire suppression system

- Water-based fire suppression system

- Gas-based fire suppression system

3. Components of the FPFF System for Pre-Engineered Steel Buildings in Vietnam:

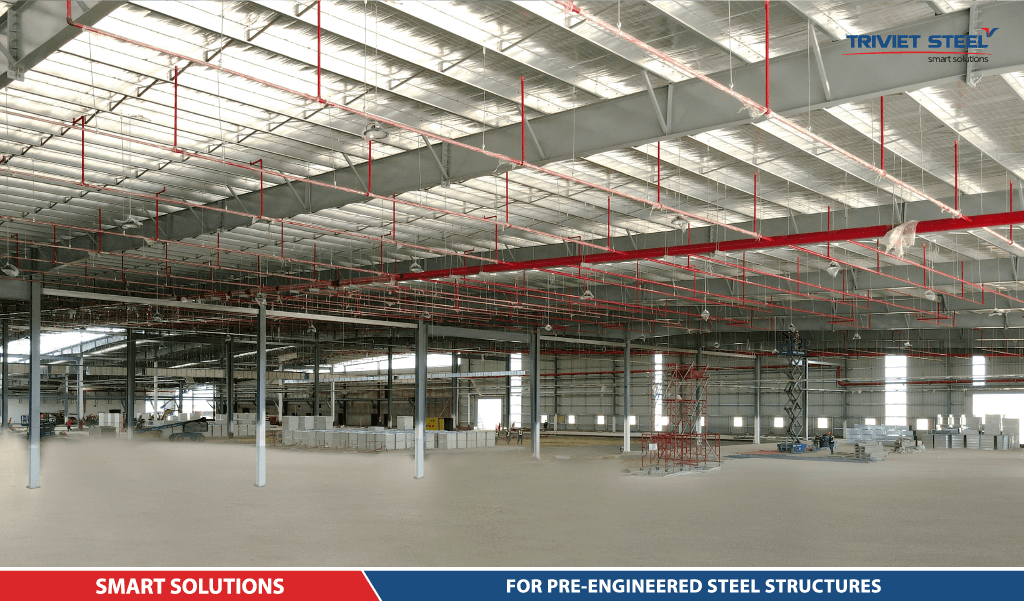

The Fire Prevention and Fire Fighting (FPFF) system is a crucial element for ensuring maximum safety in PEBs. It not only protects assets but also ensures the safety of occupants and workers. The key components of the FPFF system for PEBs are as follows:

3.1. Fire Alarm System

The fire alarm system consists of the following components:

- Fire sensors: Utilizing temperature sensors, smoke sensors, or a combination of both to detect fire incidents.

- Control panel: Receives signals from fire sensors and activates the alarm and fire suppression system.

- Alarm system: Includes audible devices such as sirens and visual devices such as flashing lights to alert occupants and surrounding individuals of a fire incident.

3.2. Fire Fighting System

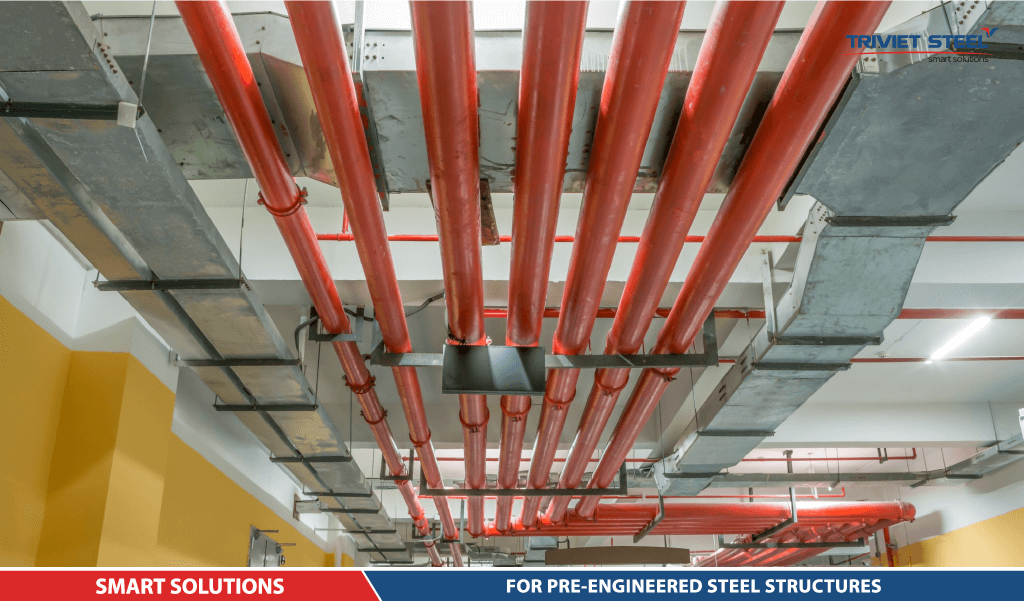

The fire fighting system comprises the following components:

- Fire extinguishers: These devices supply fire extinguishing agents such as water, fire extinguishing powder, or CO2 gas to extinguish flames.

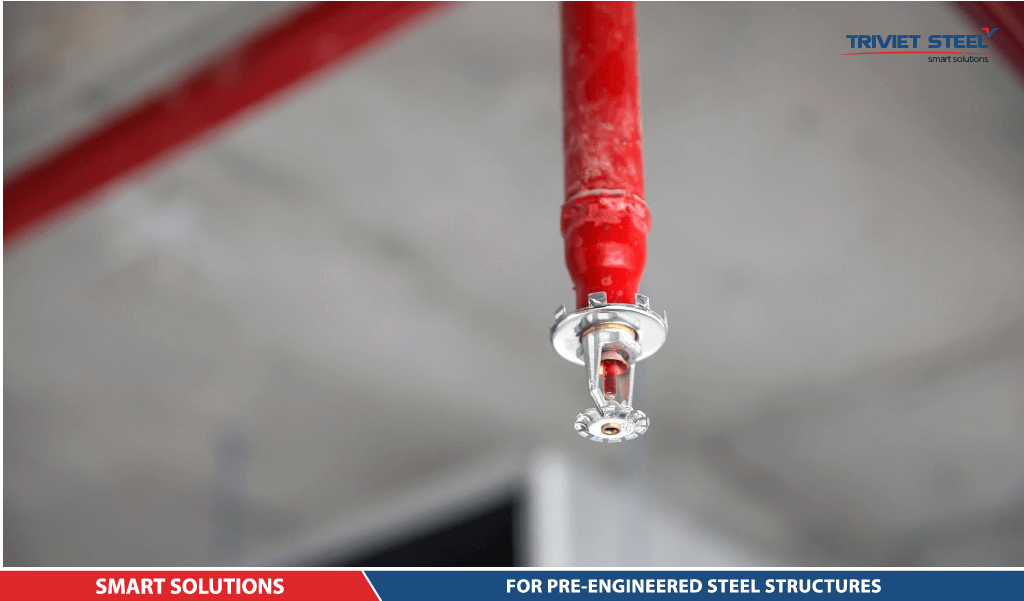

- Sprinkler system: It is an automatic water spray system installed with sprinkler heads on the ceiling or walls. When the fire sensors are triggered, water is sprayed to suppress or control the fire.

- Foam system: This system utilizes foam as a fire suppression agent to prevent fire spread by creating a foam layer on the burning surface.

- CO2 system: Carbon dioxide gas is used to create a non-combustible atmosphere, thereby extinguishing the fire.

3.3. Emergency Escape System:

The emergency escape system ensures the safe evacuation of occupants. The main components include:

- Emergency exit doors: These doors provide safe exits from the building. They must comply with regulations regarding size, location, and ease of opening.

- Emergency staircases: They provide a means of egress from higher floors of the building. Emergency staircases should be designed to withstand loads and ensure safety during use.

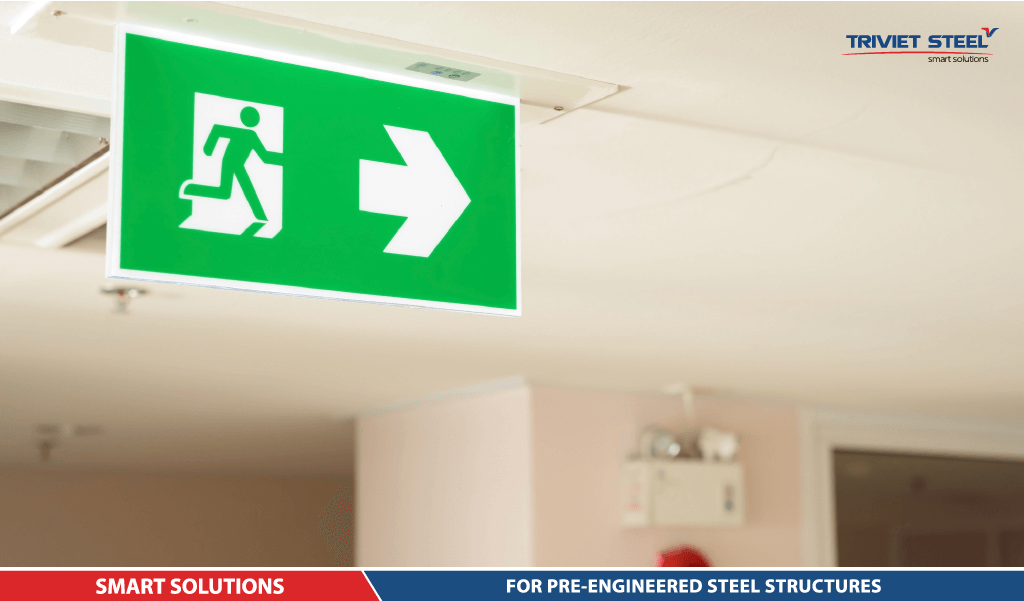

- Exit pathways: These are designated routes leading out of the building, including corridors, wide passageways, and clearly marked signs to guide people to evacuate safely.

- Smoke evacuation system: This system ensures the removal of smoke and toxic gases during the evacuation process. It may include smoke exhaust fans or ventilation systems to maintain clean air for safe evacuation.

- Emergency lighting system: It provides backup lighting in case of power failure, enabling users to see clearly and move safely during the evacuation process.

3.4. Smoke Extraction System:

The smoke extraction system plays a crucial role in ensuring the safety of occupants during a fire incident by eliminating smoke and toxic gases. This creates a safe environment for evacuation and enables effective rescue operations. The key components of this system include:

- Smoke exhaust fans: These fans are specifically designed to extract smoke and toxic gases from the building. By creating a negative pressure environment, they effectively push the smoke outside, preventing its circulation within the structure.

- Smoke ducting system: To ensure the proper direction of smoke, smoke ducts are strategically installed. These ducts serve the purpose of guiding the smoke from fire areas to the exterior of the building.

3.5. Fire-resistant Materials:

Pre-engineered steel buildings incorporate fire-resistant materials as a proactive measure to minimize the risk of fire and prevent its spread. These materials may include fire-resistant paint, fire-resistant coatings, or fire-resistant materials applied to the steel surfaces to reduce the flammability and protect the steel structure from fire damage.

4. Important Considerations for Fire Prevention and Fire Fighting in Pre-Engineered Steel Buildings in Vietnam

When designing and constructing pre-engineered steel buildings in Vietnam, it is crucial to pay attention to and comply with Fire Prevention and Fire Fighting (FPFF) regulations. This ensures that the structures not only meet safety standards but also minimize the risk of fire and explosions.

1. Expert FPFF Consultation:

Prior to commencing any construction project, it is essential to consult and collaborate with FPFF experts. They can provide specific recommendations on integrating suitable FPFF systems based on the structure and intended use of pre-engineered steel buildings.

2. Selection of Fire-Resistant Materials:

Incorporating fire-resistant materials is a critical factor in ensuring the safety of pre-engineered steel buildings. By applying fire-resistant coatings to steel structures, individuals can prevent the rapid spread of fire and protect the structural integrity of the building. This proactive measure significantly reduces the potential damage caused by fires and enhances the overall fire safety of the structure.

3. Proper Sensor Placement:

To ensure early detection of fire hazards, it is important to strategically determine the placement of fire sensors. Give priority to areas that contain electrical sources and storage areas for flammable materials.

4. Smart Fire Suppression Systems:

When selecting fire suppression systems, it is advisable to seek smart solutions. This includes automated systems that adjust water volume based on fire risks, minimizing water damage to the steel structure.

5. Employee Training:

Workers involved in the construction and operation processes should receive comprehensive training in safety and the use of FPFF equipment. Their understanding of emergency response procedures can significantly reduce the risk of fire and explosions.

6. Regular Inspections and Maintenance:

FPFF systems need to be regularly inspected to ensure their effective operation. Scheduled maintenance helps ensure that all equipment is in optimal working condition.

7. Defining Safe Zones:

When constructing pre-engineered steel buildings, identifying safe zones is crucial. This not only helps keep workers away from fire and explosion hazards but also supports emergency response procedures.

5. Tri Viet Steel Buildings – Smart Solution for Pre-Engineered Steel Buildings

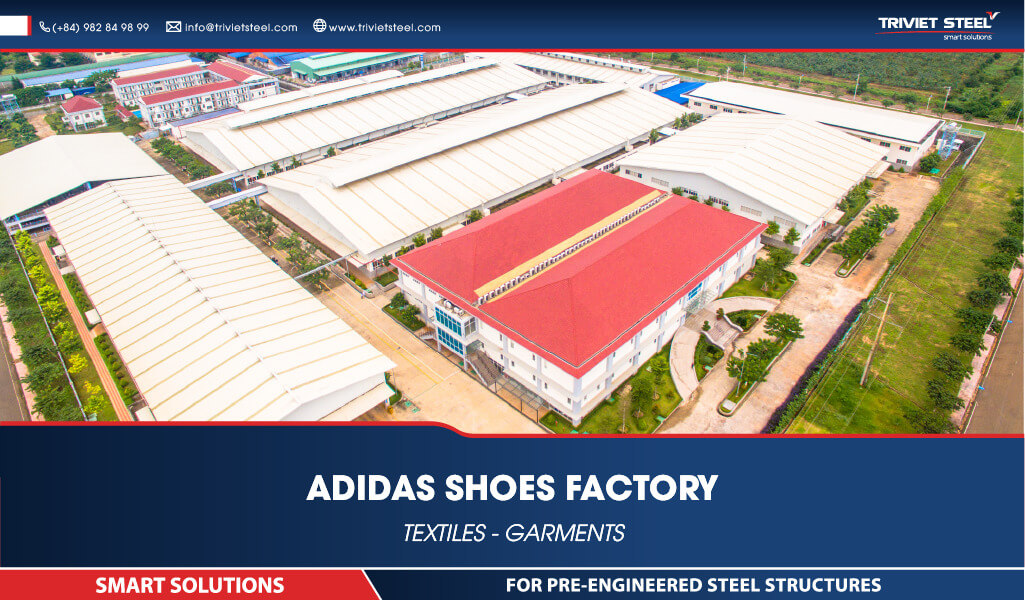

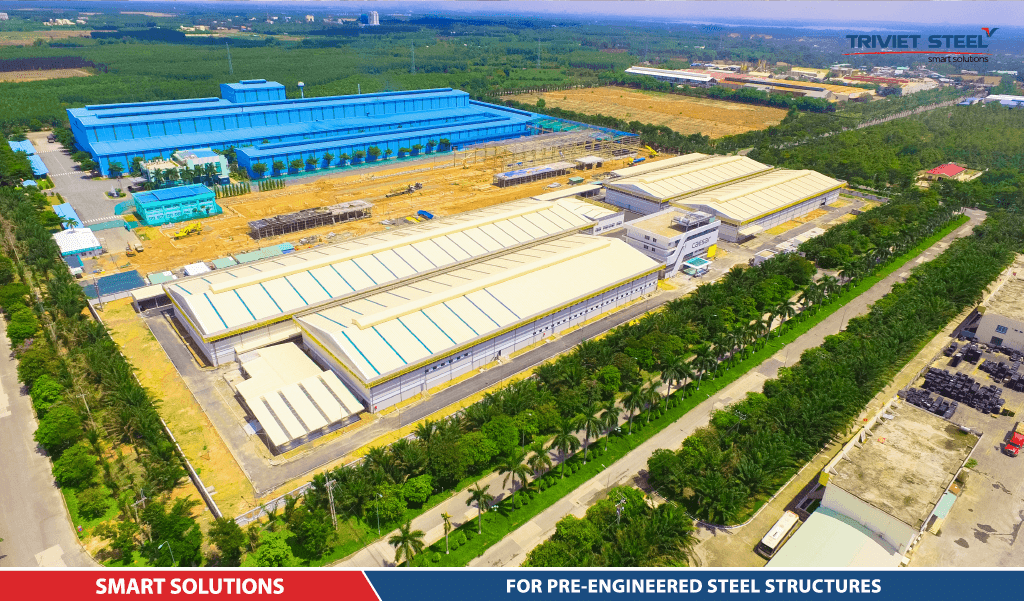

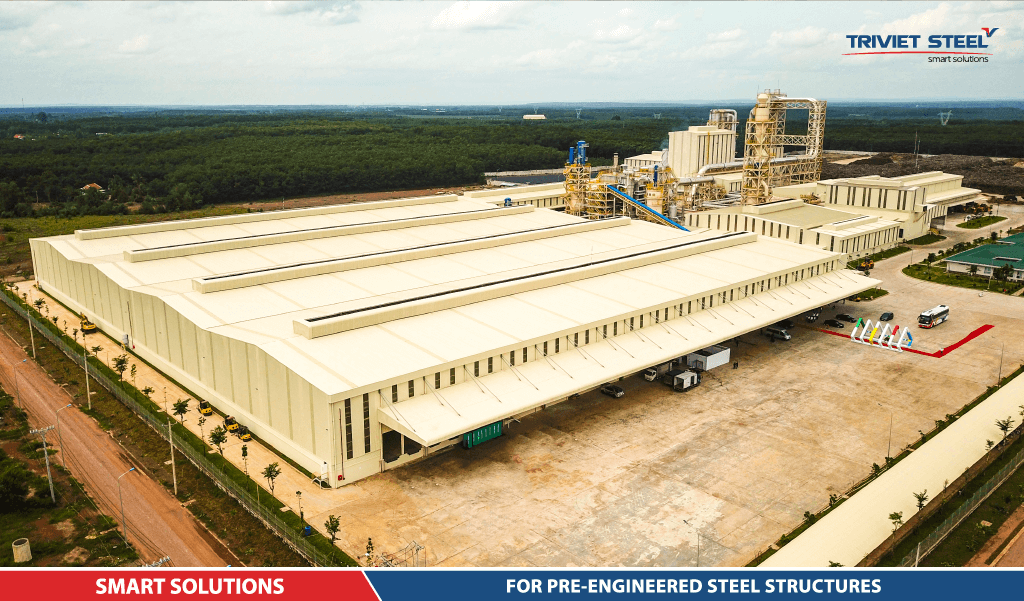

In addition to its extensive experience and successful track record, Tri Viet Steel Buildings stands out as one of the leading providers of pre-engineered steel buildings in Vietnam. With a diverse portfolio that includes residential houses, workshops, warehouses, public facilities, and commercial buildings, Tri Viet Steel Buildings offers comprehensive solutions to meet various construction needs.

When choosing Tri Viet Steel Buildings, you can expect innovative and efficient pre-engineered steel building solutions tailored to your specific needs. With their expertise and unwavering dedication, the company promises exceptional results and invites you to experience the benefits of smart construction.

English

English Tiếng Việt

Tiếng Việt