KEY FACTORS IN PREFABRICATED STEEL BUILDING CONSTRUCTION

Prefabricated Steel Buildings is increasingly chosen by businesses for the superior advantages this building method offers. So what are the benefits of Prefabricated Steel Building Construction, how much does it cost, and what are the construction steps? Keep reading this article to find the most useful information.

1. What is “Prefabricated Steel Buildings”?

Prefabricated Steel Buildings refers to a type of building that is designed and manufactured with complete parts and components at a factory. These parts are then transported to the construction site and assembled according to a predetermined design.

Prefabricated steel buildings typically have an all-steel frame structure. The building parts and components are prefabricated at the factory with high precision and good quality, then rapidly assembled on site.

Some common types of prefabricated steel buildings include:

- Industrial steel buildings: Suitable for structures like warehouses, storage facilities, or industrial facilities.

- Steel panel buildings: Consist of a steel frame, walls and roofing made of attached steel panels.

- Pre-cast steel buildings: Include a pre-cast steel frame structure and roofing materials like steel sheets or panels.

- Light steel buildings: Have a steel frame, slag wool insulation, and a design similar to conventional houses.

2. Advantages of Prefabricated Steel Buildings

Constructing prefabricated steel buildings has many superior advantages, making it an ideal choice for businesses needing to build factories or warehouses. Some key benefits of Prefabricated Steel Buildings include:

2.1. Fast Construction

Since all building parts and components are pre-manufactured, the construction process is very rapid. Typically, projects can be completed 3-4 times faster than conventional construction.

2.2. Reasonable Costs

Construction costs for prefabricated steel buildings are equal to or 10-15% lower than other building types of the same size and standards. Therefore, it is a cost-optimal investment choice.

2.3. High Quality, Long Lifespan

Prefabricated steel is manufactured in factories with modern procedures, ensuring the best quality. The durability of steel structures can be up to 50-70 years with proper maintenance.

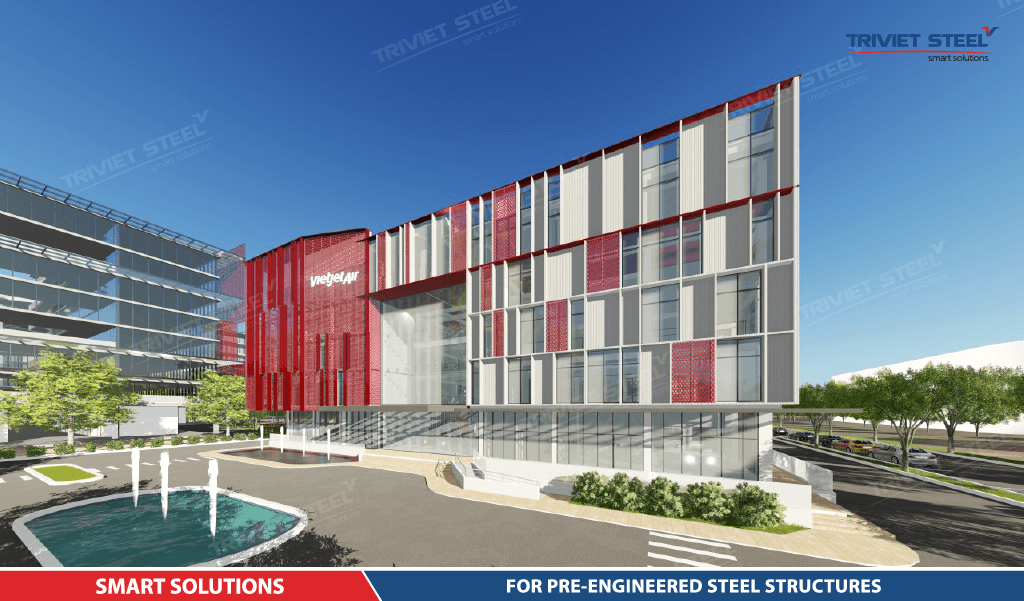

2.4. Diverse Designs

Prefabricated steel can accommodate any architectural design, from classic to modern, suitable for any lifestyle or space.

2.5. Easy Expansion and Modification

When needing to expand or modify the design, building owners simply order additional steel frames, without needing to demolish and reconstruct entirely. The process is quick, cost-efficient and safe.

2.6. Fire Resistant

Prefabricated steel buildings primarily use steel materials, giving them excellent fire resistance. The buildings ensure high safety for occupants.

3. Prefabricated Steel Building Structure

3.1. Steel Frame

The prefabricated steel frame often uses steel tubes or square hollow sections, providing good load-bearing capacity and durability. The frame bears the load and connects all building parts into an integrated unit.

Common frame types:

- Simple frames: columns, I-beams, H-beams

- Complex frames: additional wind bracing, girts, etc. to increase frame rigidity.

3.2. Roofing System

Steel building roofs typically use steel sheets, cold-formed steel or composite panels. The roofing type is chosen according to the architectural space.

Some common roofing types:

- Steel roofing: Thick anti-corrosive steel sheets.

- Cold-formed steel: Lightweight, easy installation, economical.

- Composite panels: Lightweight, good insulation, diverse colors.

3.3. Flooring System

Steel building floors often use steel decking, stainless steel or reinforced concrete. The flooring is modular for easy installation and replacement.

3.4. cladding system

The exterior of steel buildings can be clad with materials like:

- Brick walls

- Galvanized steel sheets, aluminum sheets

- Aluminum or composite panels

- Glass

Cladding with various panels and materials improves aesthetics and insulation.

4. Why Choose Steel Structure in Prefabricated Steel Building Construction ?

Steel structure is an important factor in prefabricated steel construction. Why should you consider choosing this structure? Let’s take a look at some of the key advantages.

4.1. Advantages of Steel Structures

Steel structures are a material with superior properties of durability and flexibility, allowing you to create complex architectural designs without many restrictions.

4.2. Weather Resistance

Prefabricated steel structures have better weather resistance than other materials. This is especially important when you are building in harsh climates.

4.3. Time Savings

Using prefabricated steel structures can help to reduce construction time, which can lead to labor cost savings and project optimization.

5. Latest 2023 Quotes for Prefabricated Steel Design & Construction

Design fees for prefabricated steel buildings are typically 5-10% of total construction costs. Construction costs are calculated per sqm of floor area. Currently, average market rates depend on the design complexity and construction requirements.

Additionally, construction materials account for about 60-70% of project costs. Steel pricing and secondary structures depend on the design, area and supplier.

The above only provides general market rate guidance. For detailed and accurate quotes, please contact our company directly to receive the best pricing.

6. Key Factors in Prefabricated Steel Building Construction

Prefabricated Steel Building Construction is a process that requires close coordination between designers, manufacturers, and contractors. To ensure the quality and progress of the project, it is important to pay attention to the following key factors:

1. Survey, Design

- Survey construction site, foundation soil.

- Architectural, structural and technical system designs.

- Detailed design of building parts, finishing concepts.

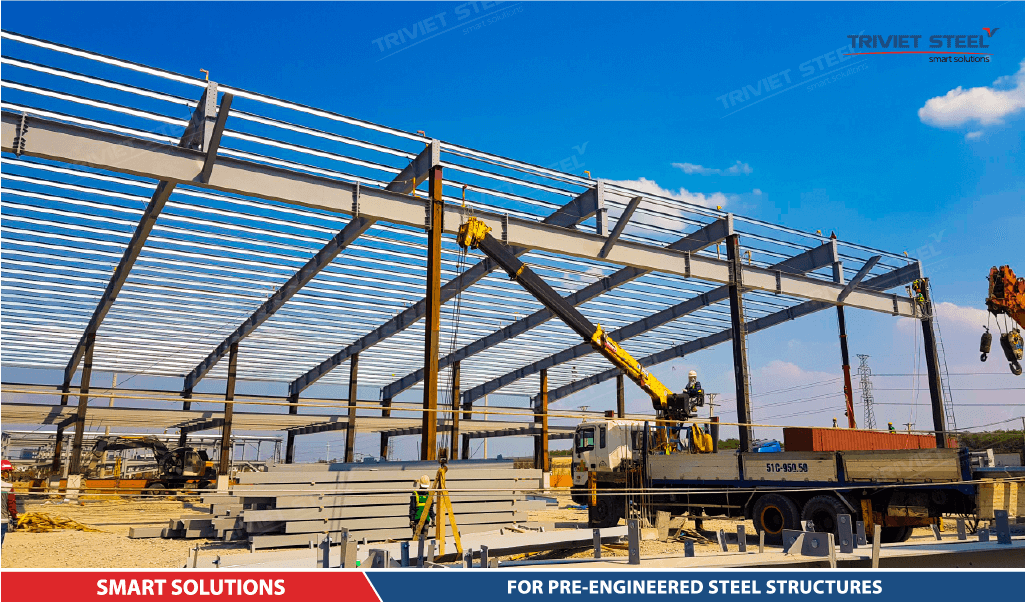

2. Manufacture Building Parts at Factory

- Fabricate steel frames, load-bearing structures.

- Fabricate interior wall partitions and cladding.

- Process all parts according to design and standards.

3. Prepare Construction Site

- Level ground surface, construct fencing.

- Build foundation, floor slab.

- Install electrical, plumbing systems per design.

4. Transport and Installation

- Transport building parts from factory to site by road or waterway.

- Use cranes/lifting equipment to position parts properly.

- Assemble each section according to design drawings.

5. Finishing

- Install exterior wall cladding, complete exterior.

- Install doors, windows, HVAC systems.

- Decorative finishes, landscaping.

- Inspection, project handover.

In summary, Prefabricated Steel Building Construction provides many benefits for large and small businesses. With rapid construction, modern technology and versatility, it meets all warehouse and factory requirements in Vietnam.

7. Key Factors in Prefabricated Steel Construction

7.1. Detailed Design

Firstly, you need a detailed design for your prefabricated steel building. Work with architects and structural engineers to ensure all aspects are carefully considered.

7.2. Steel Material Selection

Choose high-quality steel suited for your construction environment. Ensure it is protected from oxidation and corrosion.

7.3. On-Site Assembly

On-site assembly must be done precisely according to plan to avoid issues during construction.

7.4. Construction Safety

Follow all safety rules and standards to ensure worker and project safety.

7.5. Maintenance and Cost Management

Post-construction, maintenance and cost management are important. Maintain your steel building regularly to ensure optimal condition and prevent problems.

8. Choosing a Reputable Design and Construction Company

This is the most crucial factor determining build quality and costs. Do thorough research on potential design and construction companies before signing any contracts.

When selecting a design and construction firm, consider these criteria:

- Capability: The company must be capable of executing the project to exact technical specifications and timelines.

- Experience: The company should have experience in Prefabricated Steel Building Construction.

- Reputation: The company should have a good reputation in the market and positive client reviews.

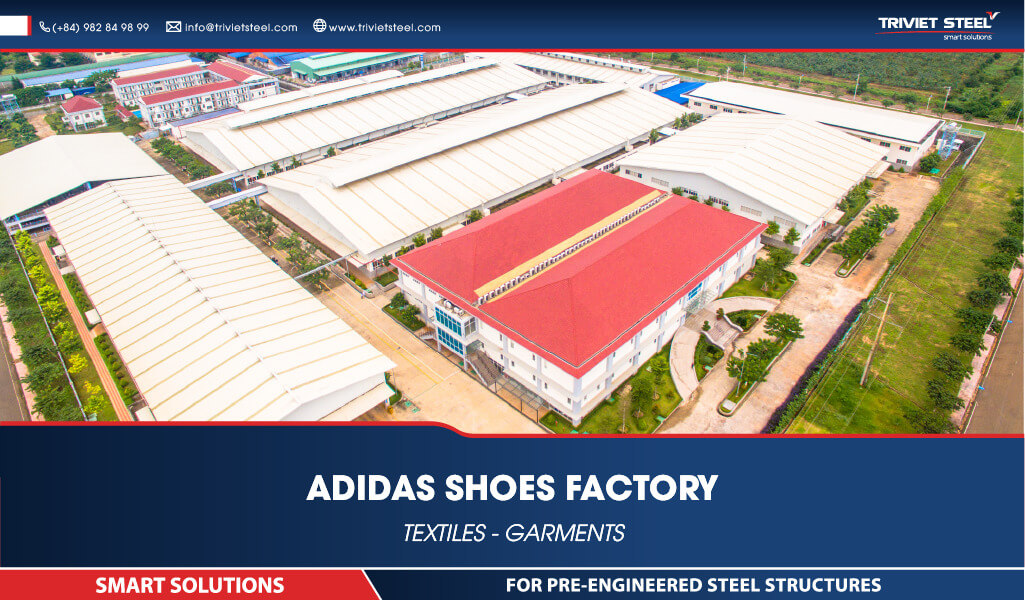

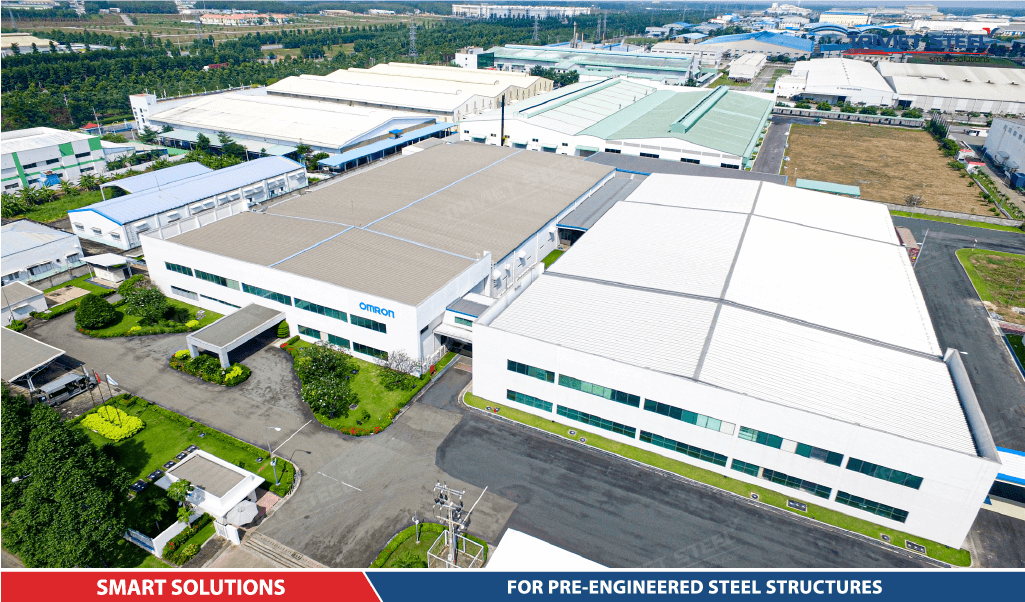

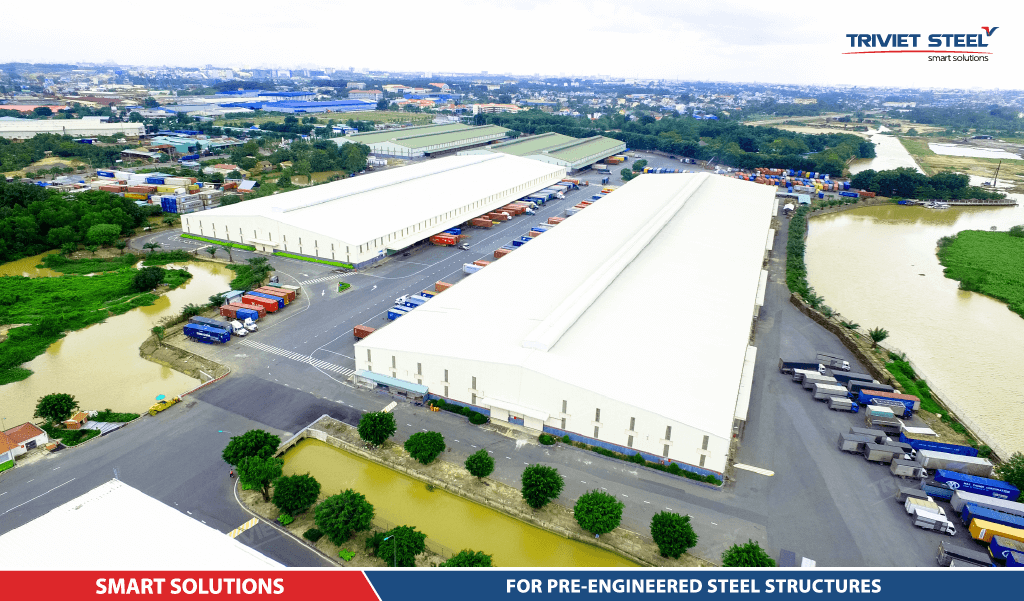

8.1. Tri Viet Steel – A Reputed Steel Structure and Prefabricated Factory Construction Company

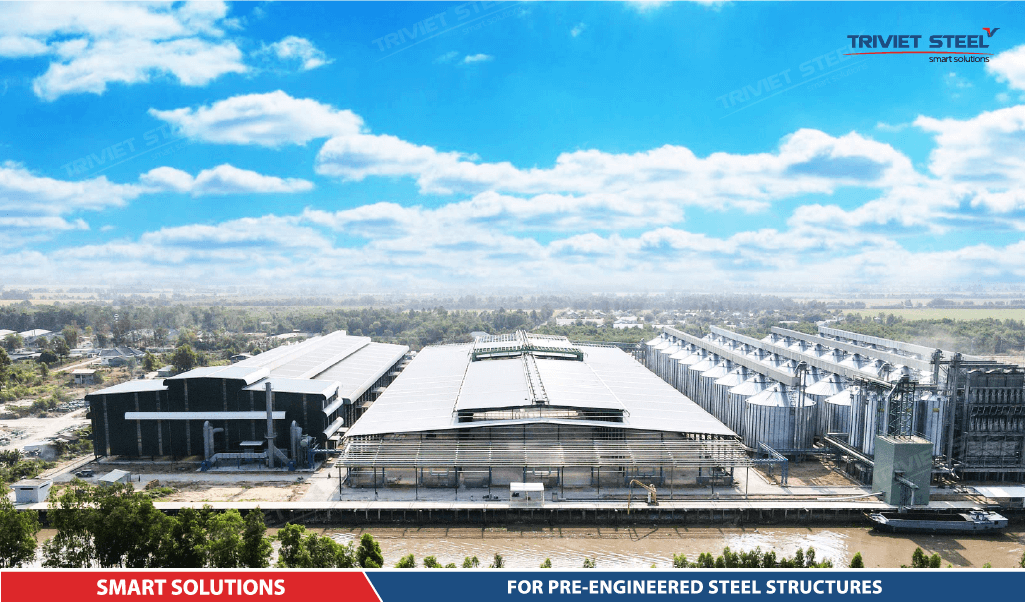

Tri Viet Steel is a leading company in the field of steel structure and prefabricated factory construction in Vietnam. With a team of skilled engineers and experienced workers, the company applies modern construction technology to deliver high-quality steel structures.

Over the course of its operation, Tri Viet Steel has completed hundreds of large and small projects across the country. Our prefabricated steel products are always guaranteed to be of the best quality, with quick turnaround times and competitive prices, bringing satisfaction to customers.

Tri Viet Steel is committed to using leading-edge technologies such as space frame systems, combined frame and bracing systems, etc. to create solid, safe steel structures in all weather conditions. In addition, we also apply closed-loop construction solutions to shorten construction time and save costs for investors.

Tri Viet Steel commits to fast construction, cost saving, customer satisfaction, and always puts reputation and product quality first.

8.2. Reasons to Choose Tri Viet Steel for Prefabricated steel building construction

Why choose Tri Viet Steel for prefabricated steel construction? This is an important question to ask when you are looking for a reliable partner for your construction project. Here are the reasons why we are confident that Tri Viet Steel is a good choice for you:

Top quality

Tri Viet Steel is committed to providing you with top-quality prefabricated steel products on the market. We use modern technology and strict quality standards to ensure that your products achieve optimal performance and long-lasting durability.

Experience and professionalism

With many years of experience in the prefabricated steel construction industry, our team of experts has been involved in and completed many large projects across the country. We understand how to coordinate and execute all tasks in a professional and efficient manner.

Convenience and time-saving

Prefabricated steel from Tri Viet Steel is manufactured in the factory, which helps to reduce on-site construction time. This not only saves time but also reduces costs and risks during construction.

Excellent customer service

We always listen to and meet all customer requirements quickly and efficiently. We are committed to working with you from the design stage to project completion to ensure that you are satisfied with the final result.

Investment value

The combination of high quality, optimal performance, and reasonable prices makes choosing Tri Viet Steel a smart investment for your project. We always strive to provide the best value for our customers.

English

English Tiếng Việt

Tiếng Việt