WHAT TYPE OF GALVANIZED IRON SHEET SHOULD PREFABRICATED STEEL WORKSHOPS USE ?

Prefabricated steel workshops using preassembled steel structures. Prefabricated steel workshops have fast construction times and low costs. The roofing is an important part of prefabricated steel workshops. It protects the structure from weather impacts like sunlight, rain, wind, etc.

Currently, there are many different types of galvanized iron sheets on the market. Each type has its own advantages and disadvantages. When selecting the appropriate roofing sheet for prefabricated steel workshops, consider factors such as roof area, climate conditions, heat resistance, and noise insulation.

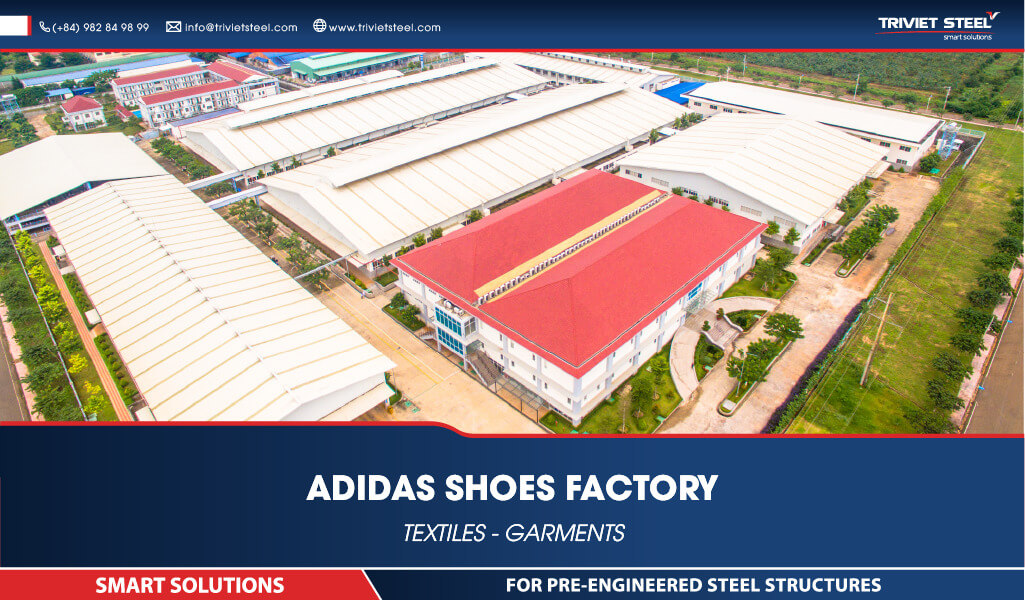

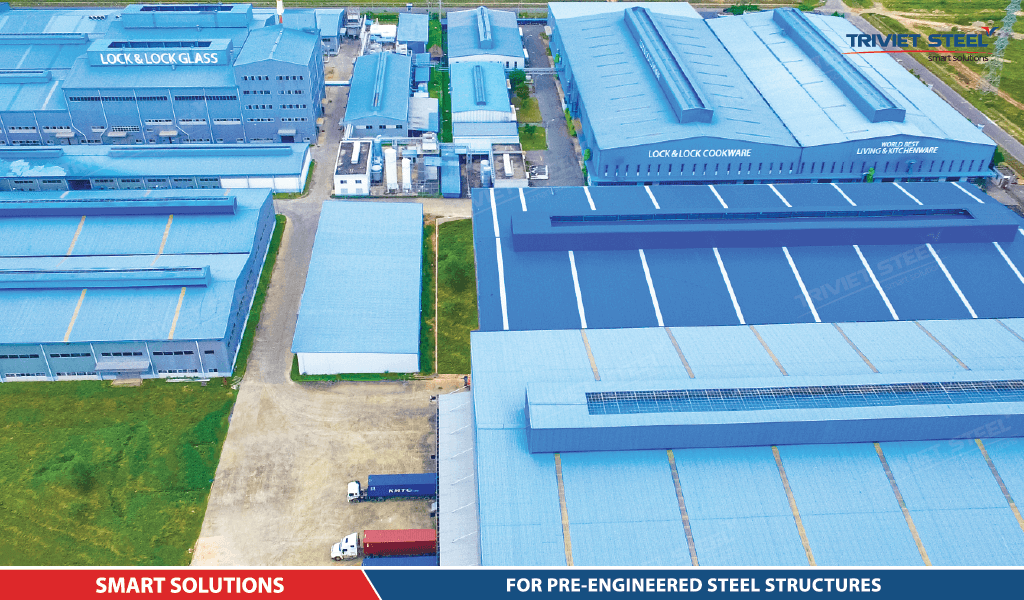

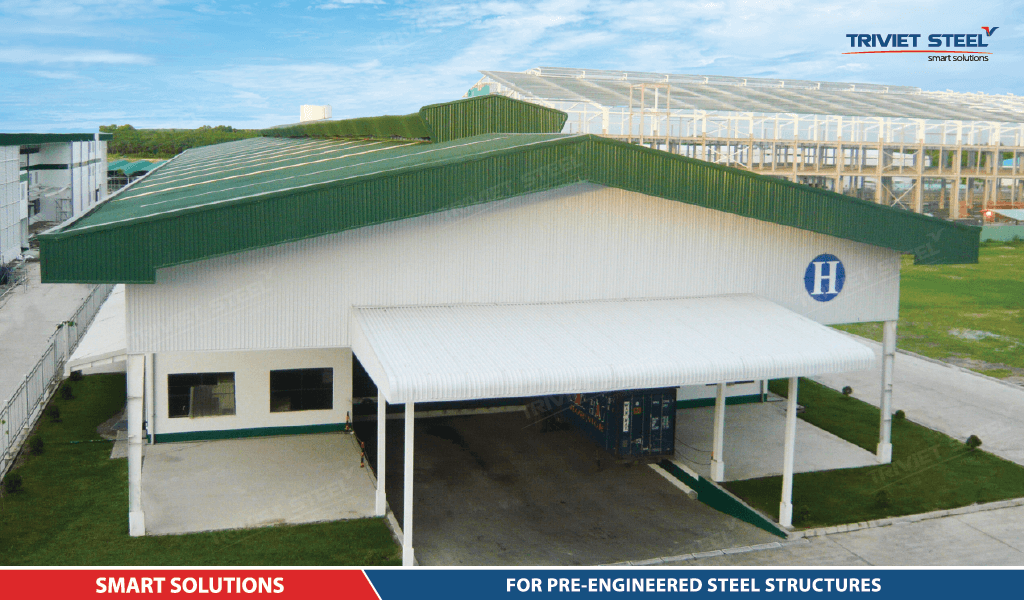

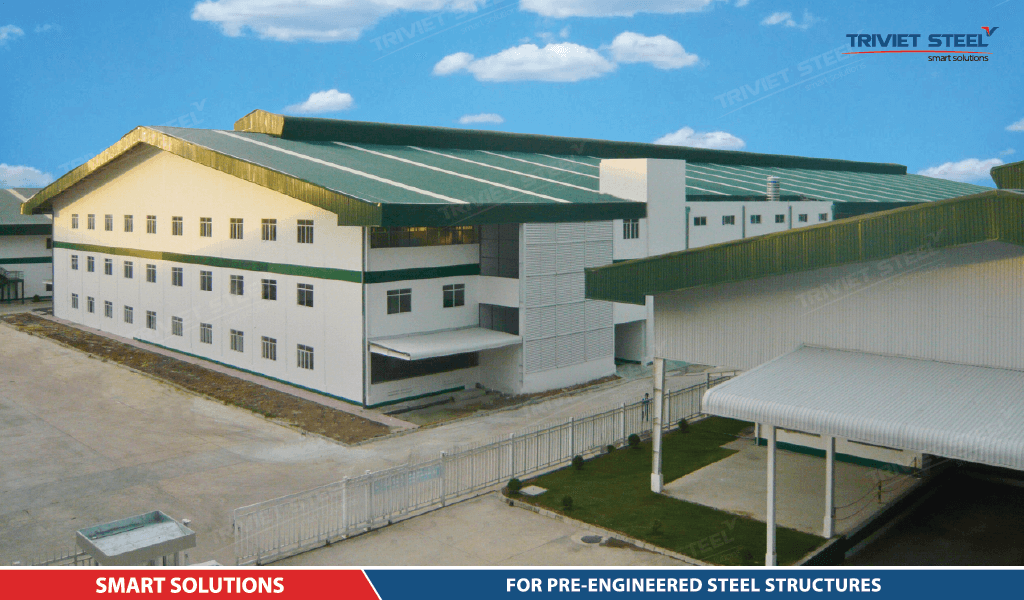

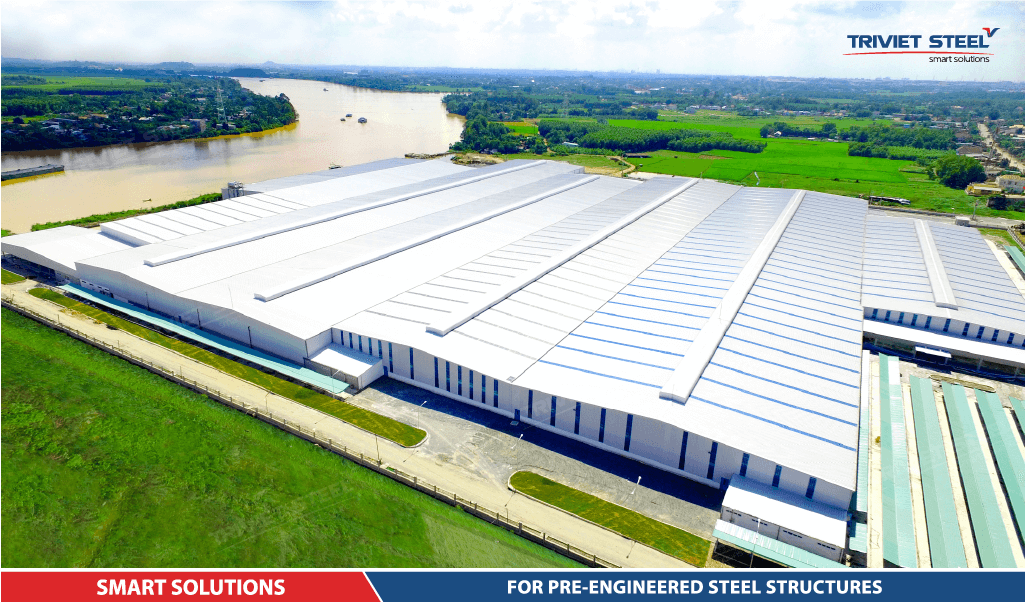

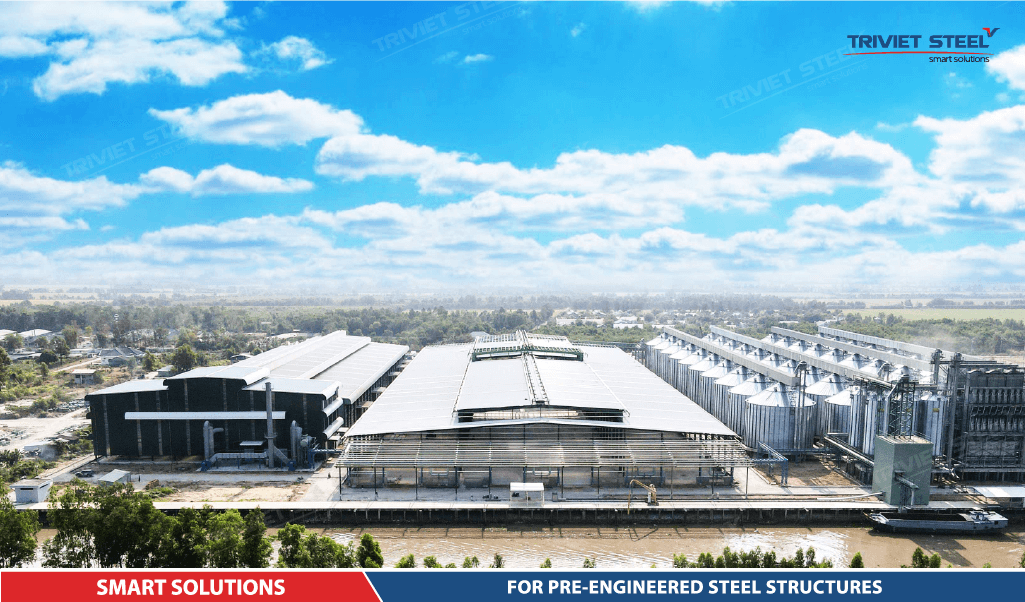

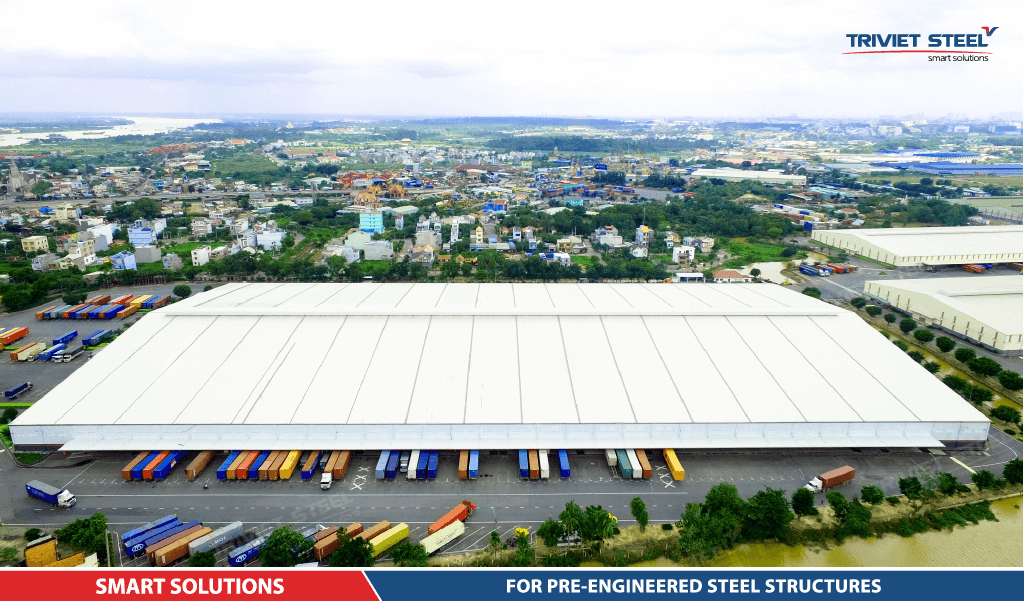

1. What are Prefabricated Steel Workshops?

Prefabricated steel workshops are an ideal solution for industrial facilities, factories, enterprises or warehouses. With the advantages of flexibility, fast construction, and reasonable costs, prefabricated steel workshops are a popular choice among project owners and businesses.

>> Read more: Pre-Engineered Steel Buildings – Construction Trend In 2023

1.1. Benefits of Prefabricated Steel Workshops

- Cost savings: No need for concrete pouring or bricklaying, costs are 20-25% lower than traditional construction.

- Fast construction time: 3-4 times faster than traditional construction methods.

- The design is flexible: allowing for easy expansion or reduction of space.

- Structural strength: Steel structures have good load-bearing capacity and high durability.

- Eco-friendly: Reusable, easy to dismantle, generates little to no construction waste.

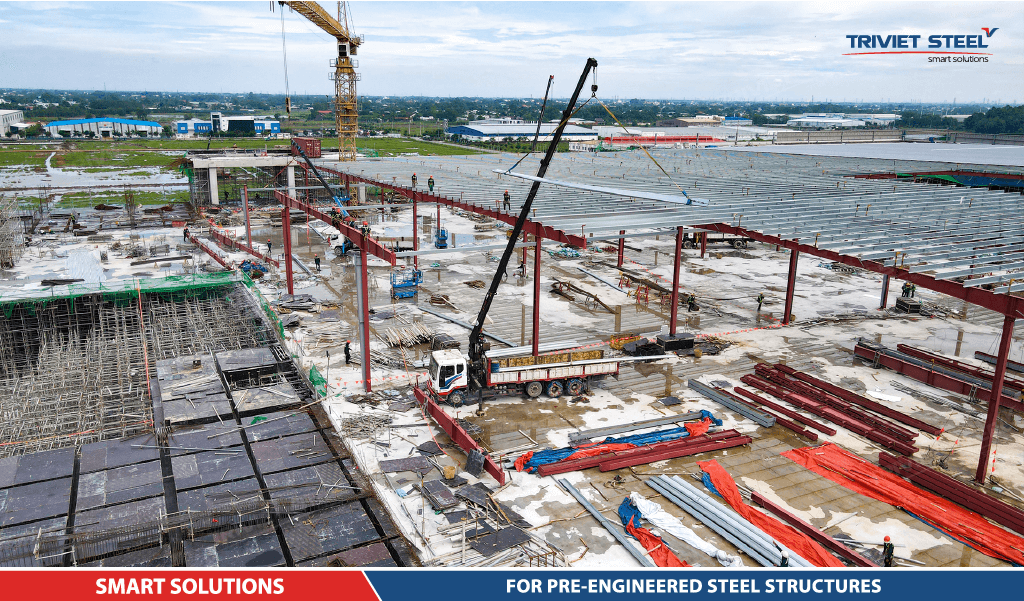

2.2. Structures of Prefabricated Steel Workshops

Prefabricated steel workshops are built with preassembled steel structures, allowing fast construction times and low costs. The structure of prefabricated steel workshops consists of 3 main components:

- Steel frame including: columns, beams, and trusses prefabricated at factories and transported to site for assembly.

- Secondary structures including: purlins, bracings, wall girts, etc.

- Accessories including: roofing, roof extensions, flashings, gutters, ridge capping, ventilation systems, stay cables, etc.

Additionally, to serve the needs of project owners and clients, prefabricated steel workshop designs can integrate the following structures:

- Mezzanine floors: Floors built at a higher level than the main workshop floor, often used for offices, rest areas, etc.

- Overhead crane beams: Load-bearing beam systems to support overhead cranes, often used in manufacturing and assembly facilities.

- Roof bracing: Additional steel structures installed to enhance roof load-bearing capacity, used for large span workshops or in areas with high winds.

- Walkways: Walkways designed within the workshop for worker and vehicle circulation.

Detailed accessories include: roofing, roof extensions, flashings, gutters, ridge capping, ventilation systems, stay cables, etc.

2. Roofing Sheet Types for Prefabricated Steel Workshops:

Roofing is an important component of prefabricated steel workshop construction. Choosing the right roofing sheet type can greatly influence the quality and performance of the building.

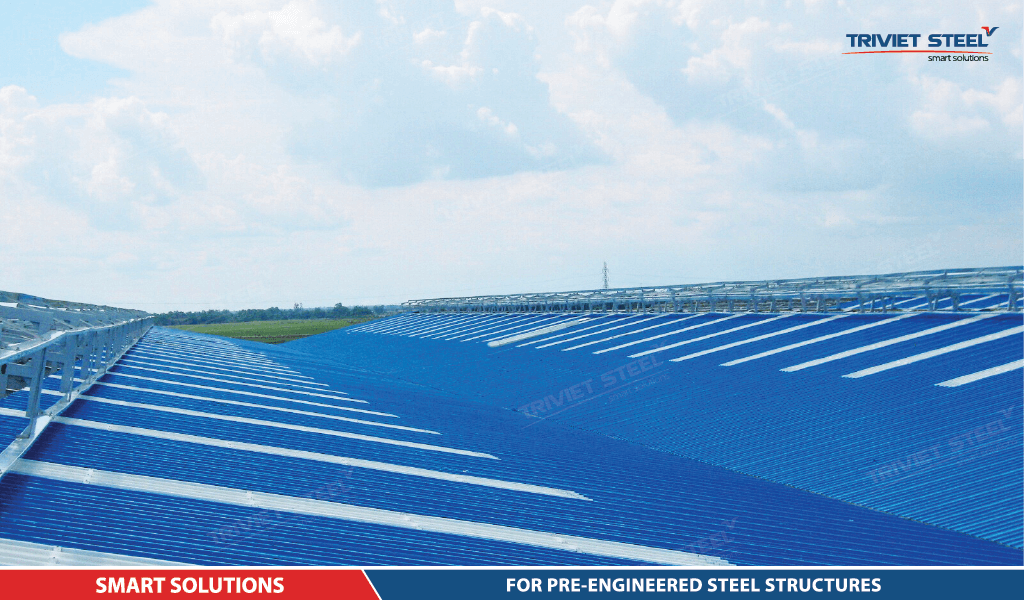

1. Trapezoidal Sheet: Stability and Water Resistance

Trapezoidal sheets, also called 5-wave sheets, are commonly used for prefabricated steel workshop roofs. Their strength lies in the relatively tall wave height, which creates a stable roof surface with good water runoff. This is especially important in high rainfall areas or when maximum weather protection is desired.

Pros:

- Good water runoff performance

- High rigidity

- Cost savings on purlins

Cons:

- Thin sheets have lower heat and noise insulation

2. Square Wave Sheet 7: Aesthetics for Wall Cladding

Square wave sheets with 7 waves are often used as wall cladding in prefabricated steel workshops. With a lower wave height compared to trapezoidal sheets, they create a smooth wall surface suitable for buildings requiring high aesthetics. Besides water resistance, this sheet type plays an important role in creating an attractive facade.

Pros:

- Good heat insulation

- Thicker sheets offer good noise insulation

Cons:

- Lower water runoff performance than trapezoidal sheet

3. Square Wave Sheet 9: Aesthetics and Contrast

Square wave sheets with 9 waves have short height and high frequency waves. This creates a unique and aesthetic wall surface. This sheet type is often used to enhance visual appeal, especially when contrast and creativity are desired. It provides an interesting option to make a distinctive statement with the workshop design.

Pros:

- High aesthetics

- Good heat insulation

Cons:

- Lower water runoff than trapezoidal sheet

4. Klip-Lock Sheet: Durability and Puncture Resistance

Klip-Lock sheets are commonly used for prefabricated steel workshop roofs. Their standout feature is interlocking joints without screws. With a tall wave height up to 84mm, Klip-Lock offers excellent puncture resistance, protecting structures from external damage.

Pros:

- Excellent puncture resistance

- Good heat and noise insulation

Cons:

- Higher cost than other sheet types

5. Seamlock Sheet

Seamlock sheet is the most premium roofing sheet today. With an extreme wave height up to 84mm, Seamlock provides absolute water runoff resistance. It also has superior heat and noise insulation capabilities.

Pros:

- Absolute water runoff resistance

- Extreme heat and noise insulation

Cons:

- The most expensive among roofing sheet types

3. The Importance of Roofing for Prefabricated Steel Workshops

The roof is a crucial part of prefabricated steel workshops, protecting the structure from adverse weather impacts. For workshops, choosing the right roofing type is extremely important as it determines the building’s lifespan and performance.

Metal roofing sheets are considered the optimal choice for most workshop buildings today, thanks to the following superior advantages:

- High structural strength and durability, able to withstand long-term weather impacts

- Lightweight, easy transportation and quick installation

- Low initial investment cost

- Long service life, good color stability, low maintenance costs

- Good aesthetics, easy to integrate with architectural designs

4. Choosing Roofing Sheets for Prefabricated Steel Workshops

When selecting roofing sheets for prefabricated steel workshops, the following should be considered:

- Roof area: Larger roof areas require sheets with taller wave height for good water runoff.

- Climate conditions: Harsh climate areas need sheets with good heat and noise insulation.

- Heat and noise insulation: Sheets with good insulation safeguard worker health and improve productivity.

- Waterproofing: Sheets with excellent waterproofing protect the structure from weather impacts.

- Load-bearing: Sheets with higher load-bearing capacity provide better structural safety.

- Cost: Roofing sheet cost depends on material, thickness, wave height, etc.

5. Why are Metal Roofing Sheets Preferred for Steel Workshops?

Metal roofing can be considered the optimal choice for most steel workshop buildings today, thanks to the following superior advantages:

- Low Initial Investment Cost

Compared to other roofing materials, metal sheets have significantly lower upfront costs, suitable for various project scales and budgets.

- Lightweight – Easy Installation

Metal sheets have relatively lightweight properties compared to bricks, tiles, cement boards, etc. Transportation and installation are easy and convenient.

- Long Lifespan and Durability

Thanks to protective anti-corrosion coatings, metal roofing has an exceptionally long lifespan and durability, lasting decades with proper maintenance.

- High Aesthetics – Design Flexibility

Metal sheets come in diverse colors and profiles to easily match any architectural design.

- Excellent Thermal and Acoustic Insulation

Metal roofs provide great thermal and noise insulation, reducing impacts from heat and ambient sounds.

- High Structural Strength

Made from steel, metal roofs have excellent rigidity and load-bearing abilities, suitable for large-scale constructions.

>> See More: Pre-Engineered Steel Buildings Installation – A Growing Trend

6. Conclusion

The roofing is a crucial component of prefabricated steel workshops. Proper consultation and selection of suitable roofing sheets are vital to ensure building aesthetics and durability.

Tri Viet Steel Building provides complete prefabricated steel workshop solutions and services with guaranteed quality. Contact us for expert consultation and product selection.

7. Tri Viet Steel Building – Quality and Finesse in Prefabricated Steel Workshop Construction

About Tri Viet Steel Building

Tri Viet Steel Building is a professional company specializing in the construction and design of prefabricated steel workshops. We take pride in combining expertise and creativity in each project. With years of experience and a talented team, we are committed to delivering optimal solutions for every construction project.

>> See More: Abouts Tri Viet Steel Building Company

Innovative and Modern Designs We focus on designing prefabricated steel workshops with a progressive and contemporary vision. Our buildings are not just functionally optimal, but also aesthetically impressive. Our projects often have a definitive shaping quality and create landmarks for the area.

Quality Manufacturing and Installation Product and service quality is always the top priority at Tri Viet Steel Building. We own state-of-the-art equipment and utilize advanced technologies to manufacture high-quality steel frames and building materials. Our experienced technical team ensures precise and safe installation.

Smart and Cost-Saving Choice Our prefabricated steel workshops not only meet functional requirements but also provide significant savings in time and resources compared to traditional construction. We are committed to optimizing our clients’ construction budgets without compromising on quality.

Comprehensive Support We provide not only excellent products and services, but also support our clients through every step of the project. From design consultancy and material selection to installation and maintenance, Tri Viet Steel Building continually adjusts and enhances the process to ensure customer satisfaction.CopyRetry

English

English Tiếng Việt

Tiếng Việt