TOP 7 COMMON MISTAKES WHEN INSTALLING PREFABRICATED STEEL BUILDINGS AND HOW TO FIX THEM

Prefabricated steel buildings are becoming increasingly popular due to their advantages of fast construction speed and reasonable cost.

Improper installation can lead to many errors, significantly impacting the project’s quality. So what are the common mistakes and how to fix them when installing prefabricated steel buildings ? Let’s find out with Tri Viet Steel Company.

>> See More: Solutions For Ventilation In Pre-Engineered Steel Frame Buildings

1. Introduction to prefabricated steel buildings

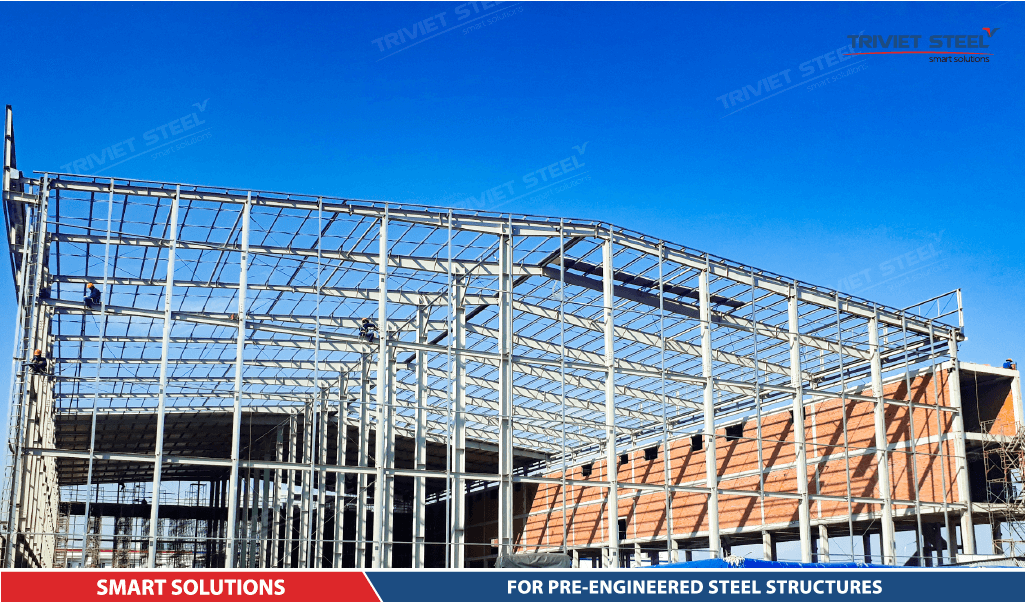

Structures designed, manufactured and assembled in a factory according to standards characterize prefabricated steel buildings. Subsequently, the components are transported to the construction site and assembled into a complete unit.

Compared to traditional construction methods, prefabricated steel buildings offer many advantages:

- Save construction time, only takes 30-40% of traditional construction.

- Investment costs are 10-15% cheaper thanks to mass production.

- The quality of the project is uniform and has fewer errors thanks to the closed process.

- Durable steel material, low maintenance, long life.

- Easy to disassemble and move if necessary.

- Environmentally friendly.

>> See More: Pre-Engineered Steel Buildings Installation – A Growing Trend

2. What is the structure of a prefabricated steel buildings ?

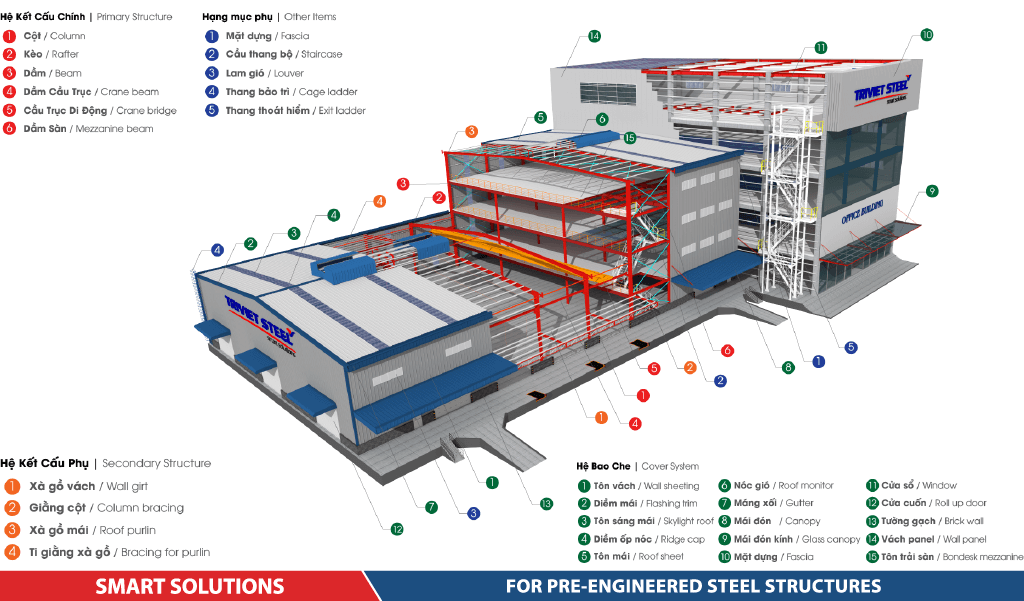

The structure of a prefabricated steel buildings is the components and parts of the buildingds made of steel. Specifically, the steel structure in a prefabricated buildings includes:

- Steel frame: columns, beams, purlins

- Roof sheeting: roof sheeting, wall sheeting

- Fastening accessories: screws, bolts, rivets, etc.

- Other parts: doors, windows, stairs, etc.

All are prefabricated with high-strength steel such as square steel, welded steel pipe, etc. to ensure firmness and good bearing capacity for the structure.

3. Advantages of the structure of a prefabricated steel buildings

- Convenience and time savings: Construction with prefabricated steel structures saves significantly more time than traditional methods. Parallel production and easy assembly help to shorten the construction time.

- Cost-effective: Manufacturing steel components in bulk helps to reduce production costs, and more efficient use of infrastructure. This often leads to lower project costs.

- Durability and safety: Steel is a strong material that can withstand the effects of weather, wind, and heavy loads. Prefabricated steel structures typically have a reliable degree of stability and durability, ensuring the safety of the structure and its users.

- Aesthetics and flexibility: Steel structures have the ability to be shaped and designed flexibly. This allows architects to express their creativity and create buildings with high aesthetic value.

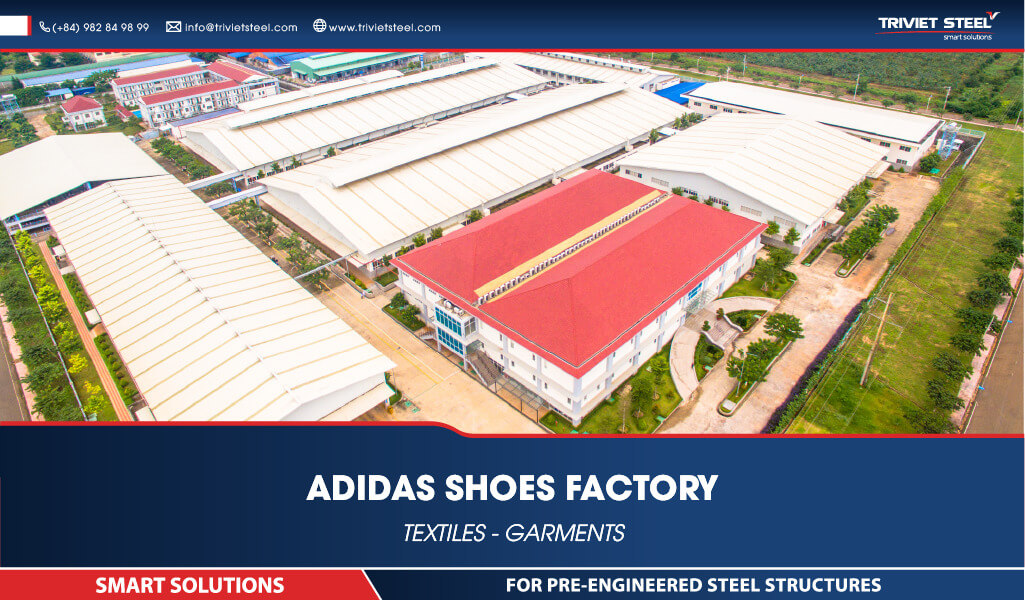

4. Applications of the structure of a prefabricated steel buildings

The structure of a prefabricated steel buildings has many applications in the construction industry:

- Residential: Prefabricated steel buildings are increasingly being used for the construction of villas, houses, and other residential houses. It brings convenience and durability to families.

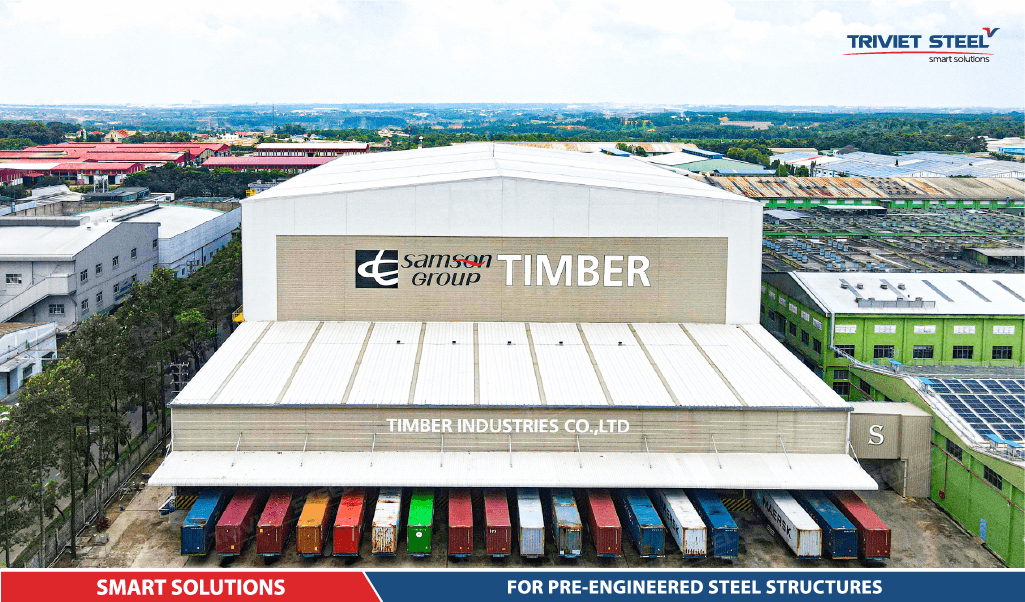

- Industrial: Steel structures are often used for factories, factories, and other industrial structures. They ensure safety and scalability.

- Commercial: In the construction of office buildings, shopping malls, and shopping centers, prefabricated steel structures are becoming the top choice with a combination of aesthetics and performance.

- Bridges and other transportation infrastructure: Steel structures are used in the construction of bridges and other transportation infrastructure due to their durability and high load bearing capacity.

- Hotels and resorts: The construction of hotels, resorts, and tourist areas with prefabricated steel structures ensures fast construction speed and high quality.

>> See More: Prefabricated Steel Building: Convenience & Modernity

5. Top 7 common mistakes when installing prefabricated steel buildings

5.1. Choosing the wrong contractor

First, choosing a contractor is essential. If you choose a company with insufficient experience and skills, it can lead to improper installation, which can seriously affect the quality of the project.

Here are some things to keep in mind when choosing a contractor:

- Choose a company with many years of experience in the field of design and construction of prefabricated steel buildings.

- Review the completed projects and customer feedback carefully.

- Prioritize companies with clear certificates and business licenses.

- Compare the construction costs of multiple companies to ensure that you are choosing the right market price.

Therefore, you need to choose reputable companies with many years of experience in the field of prefabricated steel buildings construction. At the same time, you should carefully review the completed projects and customer feedback before making a decision.

5.2. Inadequate Building Design

Proper building design is fundamental to the quality of a construction project. Flawed initial designs can result in unstable, unattractive, and inefficient structures.

Common design errors to avoid include:

- Neglecting to account for wind loads, vibrations, or heavy loads, leading to a less stable structure.

- Poor architectural design or inefficient layouts, resulting in unattractive structures and wasted space.

- Inadequate consideration for usability, circulation, and ventilation.

Therefore, select a reputable design firm with the experience and capability to ensure a sound and standards-compliant design, avoiding critical errors from the start.

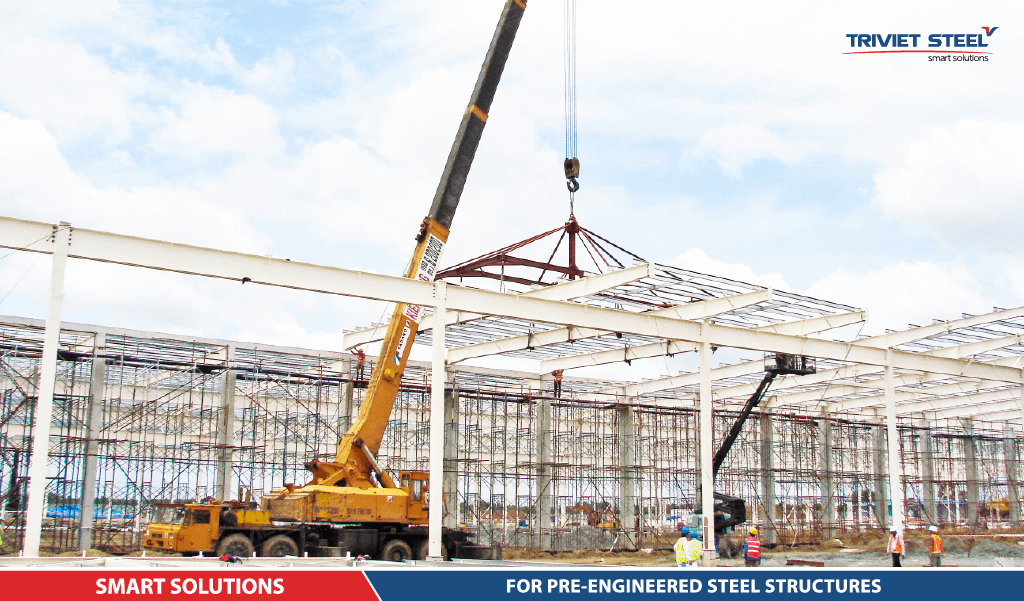

5.3. Improper transportation and storage of steel components

Careful transportation and storage of steel components are essential to prevent deformation. Errors in this process can lead to component deformities, making assembly challenging.

Here are some common issues:

- The components are not securely fixed on the transportation vehicle, leading to vibration and displacement.

- The components are exposed to direct contact with the ground, becoming damp and rusty.

- The components are stacked on top of each other, causing deformation.

- The components are not properly covered, exposing them to harsh environments such as rain, sun, salt, chemicals, etc.

The solution is to pack the components carefully, avoid moisture, and use the appropriate transportation vehicle. At the same time, secure the components firmly on the vehicle to reduce vibration and displacement.

5.4. Insufficient accuracy in installation

The installation process of the components must ensure absolute accuracy. If you are not focused or lack experience, it is easy to lead to structural misalignment, which can damage the aesthetics of the building.

To fix this, the installation workers must have high skills, follow the correct technical procedures. At the same time, use a variety of accurate measuring devices to ensure the accuracy of the building.

5.5. Use of substandard accessories and materials

The types of accessories and materials used in prefabricated steel buildings projects such as screws, bolts, insulation boards, paint, glass, etc., if not meeting the quality standards, will cause the building to deteriorate and damage easily.

To ensure quality, you need to choose to buy accessories and materials from reputable manufacturers and suppliers. Avoid using low-quality, untraceable goods to save investment costs.

5.6. Errors in finishing

After assembly, the surface finishing work such as painting, rust protection for the building is also very important. If you miss these steps, the building will quickly deteriorate.

Here are some common errors:

- Choose poor-quality paint that is not suitable for steel.

- The painting process is not meticulous, leaving gaps.

- The steel surface is not treated before painting, leading to poor adhesion.

- After construction, there are no protection measures, leaving the building exposed to the environment.

Therefore, you need to follow the correct surface finishing process, choose high-quality paint, and meticulous construction. At the same time, there should be protection measures after construction.

5.7. Lack of regular maintenance

After putting into use, regular maintenance is extremely important to extend the life of the building. However, many investors tend to ignore this.

Therefore, it is necessary to establish a regular maintenance plan every year to promptly detect and handle problems such as: roof leaks, structural damage, steel rust, etc., to extend the life of the building.

Here are some regular tasks for a prefabricated steel buildings:

- Check the roof, fix leaks if any.

- Maintain the paint, rust protection for steel components.

- Add screws, tighten joints if necessary.

- Clean drainage, sewers.

- Check electrical, water systems, repair if there is a problem.

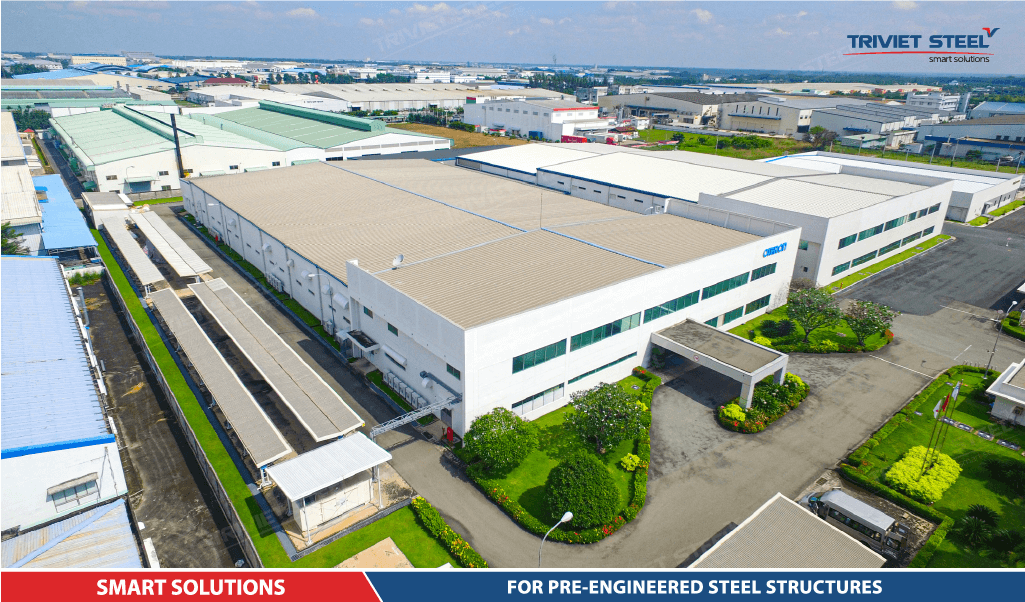

6. Tri Viet Steel – Design, Manufacturing, and Installation of Prefabricated Steel Buildings

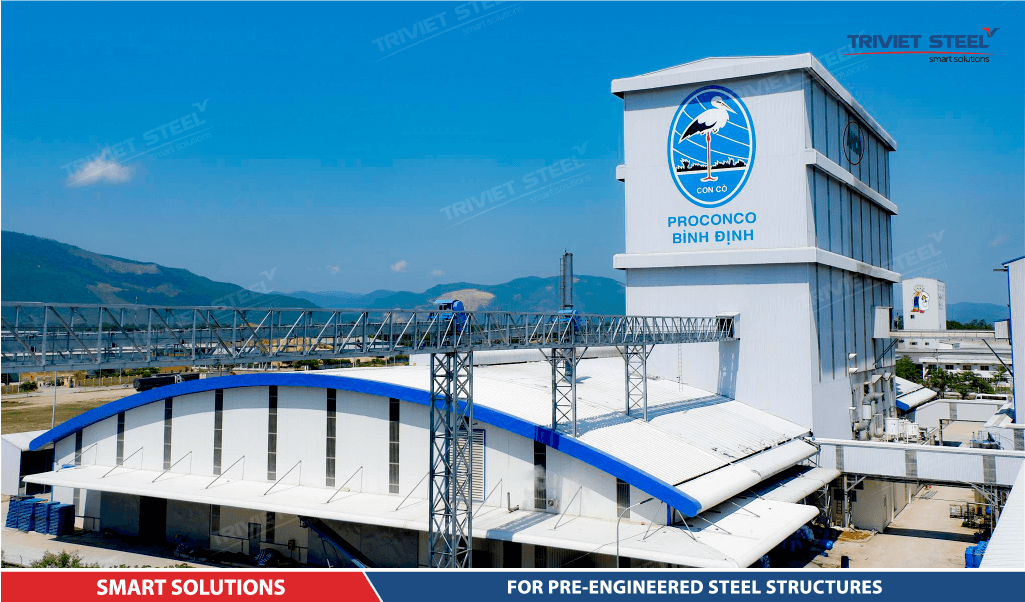

With nearly 20 years of experience in the field, Tri Viet Steel has successfully completed numerous projects across different regions. Their team of architects and engineers, rich in experience, consistently delivers unique, modern, and cost-effective designs to their clients.

>> See More: About Tri Viet Steel Building Company

Tri Viet Steel is committed to providing customers with the highest quality, reliability, and responsibility, underpinned by the core principles of “Quality – Reputation – Responsibility”. They aim to ensure complete customer satisfaction with both their products and services. Contact us today for detailed consultations.

English

English Tiếng Việt

Tiếng Việt